1. Introduction

Internal flows past flexible surfaces are important in the context of physiological flows and microfluidic applications, where flows are bounded by soft materials such as tissue or elastomers. The laminar–turbulent transition is of importance because both the drag force and the mixing rates are significantly higher in turbulent flows in comparison to laminar flows. An increase or decrease in the transition Reynolds number could affect the energy requirements and mixing rates in biological and microfluidic applications. Slow cross-stream mixing in microfluidic devices poses a technological barrier to the effective utilisation of lab-on-a-chip technologies (de Mello Reference de Mello2006; Whitesides Reference Whitesides2006). Due to the small dimension and flow velocity, the flow is laminar, and mixing takes place by molecular diffusion. Numerous novel methods have been proposed for enhancing the mixing rates, both passive (patterning grooves in channel walls (Stroock et al. Reference Stroock, Dertinger, Ajdari, Mezic, Stone and Whitesides2002), multiple bends (Liu et al. Reference Liu, Stremler, Sharp, Olsen, Santiago, Adrian, Aref and Beebe2000; Jiang et al. Reference Jiang, Drese, Hardt, Kupper and Schonfeld2004; Kane et al. Reference Kane, Hoffmann, Baumgartel, Seckler, Reichardt, Horsley, Schuler and Bakajin2008)) and active (ultrasound actuation (Ahmed et al. Reference Ahmed, Mao, Shi, Juluri and Huang2009), microstirrers (Mensing et al. Reference Mensing, Pearce, Graham and Beebe2004)). However, each of these has its disadvantages, such as an increase in pressure drop in grooved and bent channels and the requirement of expensive microfabrication in active strategies.

The diffusion coefficients of liquids comprising small molecules are of the order of

![]() $10^{-9}~\text{m}^{2}~\text{s}^{-1}$

, and the contact time required for mixing liquids across 1 mm (a typical channel width) is of the order or 1000 s. Mixing of multiple fluid streams in microfluidic devices is usually accomplished using long channels with lengths of many tens of centimetres required for a contact time of a few hundreds of seconds; these channels are curved in order to fit onto small microfluidic chips (van Berkel et al.

Reference van Berkel, Gwyer, Deane, Green, Holloway, Hollisb and Morgan2011; Han et al.

Reference Han, van Berkel, Gwyer, Capretto and Morgan2012). Due to the long path lengths and the small channel widths, large pressure drops of the order of atmospheres are required to drive the flow, and this requires pumps and compressors to be integrated into the device. This slow mixing presents a technological bottleneck to the integration of sample preparation strategies in microfluidic devices (de Mello Reference de Mello2006; Whitesides Reference Whitesides2006). Recent experiments (Verma & Kumaran Reference Verma and Kumaran2013) have demonstrated that the laminar flow in a microchannel can be destabilised at a Reynolds number much lower than the transition Reynolds number for the flow in a rigid channel if one of the walls is made sufficiently soft. The flow after transition also exhibits ultra-fast mixing and a reduction in the mixing time of up to five orders of magnitude in comparison to laminar diffusion. The flow velocities, of the order of

$10^{-9}~\text{m}^{2}~\text{s}^{-1}$

, and the contact time required for mixing liquids across 1 mm (a typical channel width) is of the order or 1000 s. Mixing of multiple fluid streams in microfluidic devices is usually accomplished using long channels with lengths of many tens of centimetres required for a contact time of a few hundreds of seconds; these channels are curved in order to fit onto small microfluidic chips (van Berkel et al.

Reference van Berkel, Gwyer, Deane, Green, Holloway, Hollisb and Morgan2011; Han et al.

Reference Han, van Berkel, Gwyer, Capretto and Morgan2012). Due to the long path lengths and the small channel widths, large pressure drops of the order of atmospheres are required to drive the flow, and this requires pumps and compressors to be integrated into the device. This slow mixing presents a technological bottleneck to the integration of sample preparation strategies in microfluidic devices (de Mello Reference de Mello2006; Whitesides Reference Whitesides2006). Recent experiments (Verma & Kumaran Reference Verma and Kumaran2013) have demonstrated that the laminar flow in a microchannel can be destabilised at a Reynolds number much lower than the transition Reynolds number for the flow in a rigid channel if one of the walls is made sufficiently soft. The flow after transition also exhibits ultra-fast mixing and a reduction in the mixing time of up to five orders of magnitude in comparison to laminar diffusion. The flow velocities, of the order of

![]() $1~\text{m}~\text{s}^{-1}$

, are significantly higher than those for conventional microfluidic devices. However, mixing is completed within a path length of the order of 2–3 cm (in contrast to the tens of centimetres required for conventional microfluidic devices). In addition, there is a significant deformation of the soft wall due to the applied pressure gradient (Gervais et al.

Reference Gervais, El-Ali, Guntherb and Jensen2006; Ozsun, Yakhot & Ekinci Reference Ozsun, Yakhot and Ekinci2013). A combination of the small path length and the channel deformation results in a pressure drop of less than 10 kPa, which is significantly smaller than the pressure drop of hundreds of kPa required in microfluidic devices based on laminar mixing, even though the flow rates are significantly higher. This fast mixing significantly enhances the feasibility of incorporating sample preparation steps into microfluidic devices. However, in order to facilitate design, it is necessary to have an accurate characterisation of the nature of the flow after transition. An experimental investigation of the mean and fluctuating velocities in a soft-walled microchannel after transition is the subject of the present study.

$1~\text{m}~\text{s}^{-1}$

, are significantly higher than those for conventional microfluidic devices. However, mixing is completed within a path length of the order of 2–3 cm (in contrast to the tens of centimetres required for conventional microfluidic devices). In addition, there is a significant deformation of the soft wall due to the applied pressure gradient (Gervais et al.

Reference Gervais, El-Ali, Guntherb and Jensen2006; Ozsun, Yakhot & Ekinci Reference Ozsun, Yakhot and Ekinci2013). A combination of the small path length and the channel deformation results in a pressure drop of less than 10 kPa, which is significantly smaller than the pressure drop of hundreds of kPa required in microfluidic devices based on laminar mixing, even though the flow rates are significantly higher. This fast mixing significantly enhances the feasibility of incorporating sample preparation steps into microfluidic devices. However, in order to facilitate design, it is necessary to have an accurate characterisation of the nature of the flow after transition. An experimental investigation of the mean and fluctuating velocities in a soft-walled microchannel after transition is the subject of the present study.

The flow in collapsible tubes is one of the widely studied internal flow models for the flow in airways. Here, there is a turbulent flow through an elastic tube with a constant external pressure. An increase in the flow rate within the tube can result in a decrease in the pressure, which leads to oscillations and collapse of the tube. These flows have been studied using low-dimensional models involving equations for the mass and the streamwise momentum averaged across the cross-section, along with an equation that relates the difference in the inside and outside pressures to the cross-sectional area (Shapiro Reference Shapiro1977; Cancelli & Pedley Reference Cancelli and Pedley1985; Jensen & Pedley Reference Jensen and Pedley1989; Pihler-Puzovic & Pedley Reference Pihler-Puzovic and Pedley2013). These models predict several interesting dynamical features such as tube collapse and steady flow in a collapsed tube (Jensen & Pedley Reference Jensen and Pedley1989), and self-excited and chaotic oscillations (Jensen & Heil Reference Jensen and Heil2003). Many of these features have been observed in experiments on collapsible tubes (Bertram Reference Bertram1986; Bertram, Raymond & Pedley Reference Bertram, Raymond and Pedley1991). In relation to the flow instability and transition problems discussed next, the work on flow through collapsible tubes considers flows that are generally already turbulent, and utilises approximate models which involve the mass and momentum equations coupled with an equation for the dependence of the cross-sectional area on the transmural pressure. The effect of laminar–turbulent transition on the tube collapse is an interesting aspect which does not seem to have received attention.

The pioneering experimental studies of Lahav, Eliezer & Silberberg (Reference Lahav, Eliezer and Silberberg1973) and Krindel & Silberberg (Reference Krindel and Silberberg1979) indicated that there could be a reduction in the transition Reynolds number in the flow through a tube if the wall of the tube was made of a soft polymer gel. A subsequent study (Yang, Grattoni & Zimmerman Reference Yang, Grattoni, Muggeridge and Zimmerman2000) suggested that the increase in the friction factor could be adequately explained without postulating a transition, but by just incorporating the change in tube shape due to the applied pressure gradient. However, the study of Krindel & Silberberg (Reference Krindel and Silberberg1979) was the first to suggest that there could be a decrease in the transition Reynolds number due to wall flexibility in parameter regimes of relevance to biological systems. The observation of Krindel & Silberberg (Reference Krindel and Silberberg1979) motivated a series of linear stability studies on the flow past viscoelastic surfaces (Kumaran Reference Kumaran2000, Reference Kumaran, Carpenter and Pedley2003). It should be noted that the transition Reynolds number in rigid tubes and channels is not accessible by linear stability studies, because the transition is highly subcritical and three-dimensional. In a rigid channel, linear stability analysis predicts that the flow becomes unstable at a Reynolds number of 5771 due to the Tollmien–Schlichting instability (Drazin & Reid Reference Drazin and Reid1981), whereas in experiments the transition is observed at a Reynolds number of approximately 1200 (Patel & Head Reference Patel and Head1969). Linear stability studies show that the flow through a rigid tube is stable at all Reynolds numbers, even though transition is experimentally observed at a Reynolds number of approximately 2100. For the flow in a conduit with soft viscoelastic walls, linear stability studies have shown that the flow can become unstable at a Reynolds number lower than the transition Reynolds number in a rigid conduit, provided that the wall is sufficiently soft. The transition in the flow through a soft conduit is qualitatively different from that in a rigid conduit in two important respects. First, the destabilisation is due to a coupling between the fluid velocity fluctuations and displacement fluctuations in the wall material, and the mechanism of destabilisation is the transfer of energy from the mean flow to the fluctuations due to the shear work done at the fluid–solid interface (in contrast to the Tollmien–Schlichting mechanism in the flow through hard-walled conduits). Second, linear stability analysis is found to accurately predict the transition Reynolds number observed in experiments.

For a soft-wall instability, the transition Reynolds number

![]() $Re_{t}=({\it\rho}VR/{\it\eta})$

is a function of the dimensionless parameter

$Re_{t}=({\it\rho}VR/{\it\eta})$

is a function of the dimensionless parameter

![]() ${\it\Sigma}=({\it\rho}GR^{2}/{\it\eta}^{2})$

and the viscosity ratio

${\it\Sigma}=({\it\rho}GR^{2}/{\it\eta}^{2})$

and the viscosity ratio

![]() ${\it\eta}_{r}=({\it\eta}_{g}/{\it\eta})$

, where

${\it\eta}_{r}=({\it\eta}_{g}/{\it\eta})$

, where

![]() ${\it\rho}$

and

${\it\rho}$

and

![]() ${\it\eta}$

are the fluid density and viscosity,

${\it\eta}$

are the fluid density and viscosity,

![]() $G$

and

$G$

and

![]() ${\it\eta}_{g}$

are the shear modulus and viscosity of the viscoelastic wall,

${\it\eta}_{g}$

are the shear modulus and viscosity of the viscoelastic wall,

![]() $R$

is the characteristic flow length scale and

$R$

is the characteristic flow length scale and

![]() $V$

is the characteristic velocity. There is an instability even in the limit of zero Reynolds number when the parameter

$V$

is the characteristic velocity. There is an instability even in the limit of zero Reynolds number when the parameter

![]() $V{\it\eta}/GR$

exceeds a critical value (Kumaran, Fredrickson & Pincus Reference Kumaran, Fredrickson and Pincus1994; Kumaran Reference Kumaran1995). The specific wall model does have a significant effect on the zero-Reynolds-number transition (Thaokar, Shankar & Kumaran Reference Thaokar, Shankar and Kumaran2001; Gkanis & Kumar Reference Gkanis and Kumar2005; Chokshi & Kumaran Reference Chokshi and Kumaran2008; Gaurav & Shankar Reference Shankar2009), and this transition is shown to be subcritical by weakly nonlinear stability analyses (Shankar & Kumaran Reference Shankar and Kumaran2001b

; Chokshi & Kumaran Reference Chokshi and Kumaran2007). Other mechanisms of instability at high Reynolds number are also qualitatively different from the instability for the flow past a rigid surface. Viscous effects are negligible in the bulk of the flow in the high-Reynolds-number ‘inviscid’ instability (Kumaran Reference Kumaran1996; Shankar & Kumaran Reference Shankar and Kumaran1999, Reference Shankar and Kumaran2000), though they are significant in boundary layers of thickness

$V{\it\eta}/GR$

exceeds a critical value (Kumaran, Fredrickson & Pincus Reference Kumaran, Fredrickson and Pincus1994; Kumaran Reference Kumaran1995). The specific wall model does have a significant effect on the zero-Reynolds-number transition (Thaokar, Shankar & Kumaran Reference Thaokar, Shankar and Kumaran2001; Gkanis & Kumar Reference Gkanis and Kumar2005; Chokshi & Kumaran Reference Chokshi and Kumaran2008; Gaurav & Shankar Reference Shankar2009), and this transition is shown to be subcritical by weakly nonlinear stability analyses (Shankar & Kumaran Reference Shankar and Kumaran2001b

; Chokshi & Kumaran Reference Chokshi and Kumaran2007). Other mechanisms of instability at high Reynolds number are also qualitatively different from the instability for the flow past a rigid surface. Viscous effects are negligible in the bulk of the flow in the high-Reynolds-number ‘inviscid’ instability (Kumaran Reference Kumaran1996; Shankar & Kumaran Reference Shankar and Kumaran1999, Reference Shankar and Kumaran2000), though they are significant in boundary layers of thickness

![]() $Re^{-1/2}$

at the walls. Similarly to the Tollmien–Schlichting mechanism, there is an internal critical layer of thickness

$Re^{-1/2}$

at the walls. Similarly to the Tollmien–Schlichting mechanism, there is an internal critical layer of thickness

![]() $Re^{-1/3}$

within the flow where the wave speed is equal to the flow velocity. The transition Reynolds number follows the scaling

$Re^{-1/3}$

within the flow where the wave speed is equal to the flow velocity. The transition Reynolds number follows the scaling

![]() $Re_{t}\propto {\it\Sigma}^{1/2}$

. The destabilising mechanism in the ‘wall mode’ instability at high Reynolds numbers (Kumaran Reference Kumaran1998; Shankar & Kumaran Reference Shankar and Kumaran2001a

, Reference Shankar and Kumaran2002) is the transfer of energy from the mean flow to the fluctuations due to the shear work at the interface. The viscous stress perturbations are important in a wall layer of thickness

$Re_{t}\propto {\it\Sigma}^{1/2}$

. The destabilising mechanism in the ‘wall mode’ instability at high Reynolds numbers (Kumaran Reference Kumaran1998; Shankar & Kumaran Reference Shankar and Kumaran2001a

, Reference Shankar and Kumaran2002) is the transfer of energy from the mean flow to the fluctuations due to the shear work at the interface. The viscous stress perturbations are important in a wall layer of thickness

![]() $Re^{-1/3}$

at the wall, and the transition Reynolds number scales as

$Re^{-1/3}$

at the wall, and the transition Reynolds number scales as

![]() $Re_{t}\propto {\it\Sigma}^{3/4}$

. Weakly nonlinear studies indicate that this instability is supercritical (Chokshi & Kumaran Reference Chokshi and Kumaran2009).

$Re_{t}\propto {\it\Sigma}^{3/4}$

. Weakly nonlinear studies indicate that this instability is supercritical (Chokshi & Kumaran Reference Chokshi and Kumaran2009).

The viscous instability has been verified in experiments (Kumaran & Muralikrishnan Reference Kumaran and Muralikrishnan2000; Muralikrishnan & Kumaran Reference Muralikrishnan and Kumaran2002; Eggert & Kumar Reference Eggert and Kumar2004), where a Couette flow was set up in a commercial rheometer between a soft polyacrylamide gel as the bottom surface and a rotating top plate, and a viscous silicone oil (with viscosity

![]() $10^{3}$

times that of water) was sheared in the gap between the two surfaces. The transition value of

$10^{3}$

times that of water) was sheared in the gap between the two surfaces. The transition value of

![]() $(V{\it\eta}/GR)$

for the destabilisation of the viscous modes is in quantitative agreement with theoretical predictions, and experiments also confirmed that the bifurcation is subcritical. Thus, the low-Reynolds-number instability phenomenon is now well understood both in theory and in experiments. In contrast, the practical realisation of the high-Reynolds-number instability was not considered feasible for a some time after the theory was formulated. In tubes and channels, the transition Reynolds number for the inviscid and wall mode instability is lower than that for transition in a rigid conduit only for low values of the parameter

$(V{\it\eta}/GR)$

for the destabilisation of the viscous modes is in quantitative agreement with theoretical predictions, and experiments also confirmed that the bifurcation is subcritical. Thus, the low-Reynolds-number instability phenomenon is now well understood both in theory and in experiments. In contrast, the practical realisation of the high-Reynolds-number instability was not considered feasible for a some time after the theory was formulated. In tubes and channels, the transition Reynolds number for the inviscid and wall mode instability is lower than that for transition in a rigid conduit only for low values of the parameter

![]() ${\it\Sigma}$

, which requires a small characteristic dimension (1 mm or less) and unrealistically low shear modulus

${\it\Sigma}$

, which requires a small characteristic dimension (1 mm or less) and unrealistically low shear modulus

![]() $G$

of a few tens of pascals. In soft solids such as polymer gels, the lowest feasible shear modulus is of the order of a few thousands of pascals. For such solids, the transition Reynolds number for the wall mode and inviscid mode instabilities is higher than the transition Reynolds number in a rigid conduit even for characteristic dimension

$G$

of a few tens of pascals. In soft solids such as polymer gels, the lowest feasible shear modulus is of the order of a few thousands of pascals. For such solids, the transition Reynolds number for the wall mode and inviscid mode instabilities is higher than the transition Reynolds number in a rigid conduit even for characteristic dimension

![]() $100~{\rm\mu}\text{m}$

to 1 mm. The value of

$100~{\rm\mu}\text{m}$

to 1 mm. The value of

![]() ${\it\Sigma}$

could be reduced by decreasing the characteristic dimensions of the conduit to tens of microns or less or using fluids of very high viscosity, but this would require a very large pressure difference to generate the velocity required for transition; such high pressure differences on conduits of small dimensions are likely to result in mechanical failure.

${\it\Sigma}$

could be reduced by decreasing the characteristic dimensions of the conduit to tens of microns or less or using fluids of very high viscosity, but this would require a very large pressure difference to generate the velocity required for transition; such high pressure differences on conduits of small dimensions are likely to result in mechanical failure.

Recent experiments (Verma & Kumaran Reference Verma and Kumaran2012, Reference Verma and Kumaran2013, Reference Verma and Kumaran2015) have shown that the high-Reynolds-number instability can be practically realised at a Reynolds number as low as 500 in tubes of diameter approximately 1 mm and length approximately 10 cm if the wall is made sufficiently soft, and at a minimum Reynolds number of 200 in a microchannel of length 3 cm, width (spanwise direction) approximately 1.5 mm and height

![]() $100~{\rm\mu}\text{m}$

if one of the walls is made sufficiently soft. The flow instability was found to be accompanied by the onset of wall motion. Different techniques were used for observing the instability of the laminar flow. In the dye-stream method, a dye is introduced at the centre, and the breakup of the dye is an indicator of the instability. The pressure difference across a deformed channel or tube was also compared with the computed prediction for the laminar flow in a channel or tube of the same shape using a finite difference scheme, and transition was inferred when the theoretical prediction was significantly lower than the experimental result, indicating that the flow had transitioned from a laminar to a more complicated velocity profile. In order to detect wall oscillations, fluorescent microbeads were embedded in the soft wall, and the motion of the beads was analysed using laser scattering. All three experimental measurements indicated that a flow instability and a transition to a non-laminar velocity profile occur simultaneously with the onset of wall motion. In both tubes and microchannels, the instability was observed at a Reynolds number smaller, by a factor of approximately 10, than that predicted theoretically for a parabolic flow in a channel or tube with a constant pressure gradient (Gaurav & Shankar Reference Shankar2009, Reference Shankar2010). A linear stability analysis indicated that the flow stability is significantly affected by wall deformation due to the applied pressure gradient. There is an expansion of the conduit close to the inlet, and then a contraction further downstream. This results in a modification of the velocity profile, and the pressure gradient is not a constant in the flow direction. When the modification of the pressure gradient and the velocity profile due to wall deformation is incorporated in the analysis, the predicted transition Reynolds number is in quantitative agreement with experimental results (Verma & Kumaran Reference Verma and Kumaran2013, Reference Verma and Kumaran2015). Linear stability analysis also predicts that the instability first occurs in the downstream converging section of the conduit, and not in the upstream diverging section; this is also in agreement with experimental observations.

$100~{\rm\mu}\text{m}$

if one of the walls is made sufficiently soft. The flow instability was found to be accompanied by the onset of wall motion. Different techniques were used for observing the instability of the laminar flow. In the dye-stream method, a dye is introduced at the centre, and the breakup of the dye is an indicator of the instability. The pressure difference across a deformed channel or tube was also compared with the computed prediction for the laminar flow in a channel or tube of the same shape using a finite difference scheme, and transition was inferred when the theoretical prediction was significantly lower than the experimental result, indicating that the flow had transitioned from a laminar to a more complicated velocity profile. In order to detect wall oscillations, fluorescent microbeads were embedded in the soft wall, and the motion of the beads was analysed using laser scattering. All three experimental measurements indicated that a flow instability and a transition to a non-laminar velocity profile occur simultaneously with the onset of wall motion. In both tubes and microchannels, the instability was observed at a Reynolds number smaller, by a factor of approximately 10, than that predicted theoretically for a parabolic flow in a channel or tube with a constant pressure gradient (Gaurav & Shankar Reference Shankar2009, Reference Shankar2010). A linear stability analysis indicated that the flow stability is significantly affected by wall deformation due to the applied pressure gradient. There is an expansion of the conduit close to the inlet, and then a contraction further downstream. This results in a modification of the velocity profile, and the pressure gradient is not a constant in the flow direction. When the modification of the pressure gradient and the velocity profile due to wall deformation is incorporated in the analysis, the predicted transition Reynolds number is in quantitative agreement with experimental results (Verma & Kumaran Reference Verma and Kumaran2013, Reference Verma and Kumaran2015). Linear stability analysis also predicts that the instability first occurs in the downstream converging section of the conduit, and not in the upstream diverging section; this is also in agreement with experimental observations.

Large velocity fluctuations in the spanwise direction were observed after transition in the microchannel experiments of Verma & Kumaran (Reference Verma and Kumaran2013) in microchannels of length approximately 3 cm. These fluctuations resulted in ultra-fast mixing between two streams that were introduced side-by-side in the microchannel. Mixing was characterised in two ways. The first was by pumping in two fluid streams of different colour through two adjacent inlets, and visually characterising the mixing by image analysis. The second was by separating out the two inlet streams at the outlet in a symmetric manner, and using conductivity measurements to determine the extent of mixing. These measurements indicated that the time required for complete mixing, which is a few tens of milliseconds, is lower, by five orders of magnitude, in comparison to the time required for molecular diffusion in a laminar flow across a distance of approximately 1 mm. This rapid mixing was accompanied by a relatively small increase in the pressure difference required to drive the flow, because the channel expansion due to the pressure difference results in a higher cross-sectional area and lower flow resistance.

It is important to reiterate that the mechanism of destabilisation, which involves a coupling between fluid and wall dynamics, is qualitatively different from that for transition in a rigid channel, and all of the available evidence indicates that the transition is accurately predicted by a linear stability analysis. A critical gap in our current understanding is the nature of the flow after transition. Experiments do show large velocity fluctuations in the spanwise direction along the width of the microchannel after transition, indicating that the flow is three-dimensional. However, there are no direct velocity measurements in the direction perpendicular to the soft wall across the smallest dimension of the channel, in which the mean velocity gradient is the largest. The objective of this paper is to examine the nature of the flow after the instability of the laminar flow. Dye-stream experiments were carried out by Verma & Kumaran (Reference Verma and Kumaran2013), where they introduced a dye at the centre of the channel and visualised the progression of the dye downstream. In these experiments, regular patterns were not observed, but there was a catastrophic breakup of the dye stream at transition. This motivates us to examine whether the flow transition exhibits the features of turbulence, by comparing the flow features with those of turbulence in rigid channels.

Here, we study the nature of the velocity profile in the case where the transition is induced by a dynamical interaction between the fluid and a soft wall when the flow length scale is of the order of

![]() $200{-}300~{\rm\mu}\text{m}$

. Since transition occurs at a Reynolds number of approximately 250 for the softest gels used here, the nature of the flow after transition is compared with turbulent flows in rigid channels at much higher Reynolds numbers. Of interest are the magnitudes of the velocity fluctuations (when scaled by the maximum velocity or friction velocity), as well as the shape of the profiles of the mean velocity (specifically the presence of the viscous sublayer, buffer layer and logarithmic layer), the root mean square of the fluctuating velocities (the near-wall peak in the intensity of the streamwise fluctuating velocity and the Reynolds stress profiles) and the fluctuating energy production rates. In a rigid-walled channel, all components of the fluctuating velocity decrease to zero due to the no-slip condition, and so the mean square of the fluctuating velocities, Reynolds stress and fluctuating energy production rate are zero at the wall. In a soft-walled channel, there could be wall motion due to the stresses exerted by the flow, and so there is the possibility that the mean square of the fluctuating velocities and the Reynolds stress are not zero at the wall. In addition, the mechanism of destabilisation of the laminar flow is the transfer of energy from the mean flow to the fluctuations due to the shear work done at the fluid–solid interface. If this mechanism persists after transition, there is the possibility that the fluctuating energy production is a maximum at the fluid–solid interface.

$200{-}300~{\rm\mu}\text{m}$

. Since transition occurs at a Reynolds number of approximately 250 for the softest gels used here, the nature of the flow after transition is compared with turbulent flows in rigid channels at much higher Reynolds numbers. Of interest are the magnitudes of the velocity fluctuations (when scaled by the maximum velocity or friction velocity), as well as the shape of the profiles of the mean velocity (specifically the presence of the viscous sublayer, buffer layer and logarithmic layer), the root mean square of the fluctuating velocities (the near-wall peak in the intensity of the streamwise fluctuating velocity and the Reynolds stress profiles) and the fluctuating energy production rates. In a rigid-walled channel, all components of the fluctuating velocity decrease to zero due to the no-slip condition, and so the mean square of the fluctuating velocities, Reynolds stress and fluctuating energy production rate are zero at the wall. In a soft-walled channel, there could be wall motion due to the stresses exerted by the flow, and so there is the possibility that the mean square of the fluctuating velocities and the Reynolds stress are not zero at the wall. In addition, the mechanism of destabilisation of the laminar flow is the transfer of energy from the mean flow to the fluctuations due to the shear work done at the fluid–solid interface. If this mechanism persists after transition, there is the possibility that the fluctuating energy production is a maximum at the fluid–solid interface.

There are several challenges in setting up the experiments and carrying out the experimental measurements. There is a significant deformation of the soft wall due to the pressure gradient across the channel, and so the cross-section is not rectangular in our experiments. The measurements are carried out only in the downstream section where the channel is converging and the slope of the wall is small, so that the mean flow along the central plane of the channel is close to a two-dimensional flow. However, the velocity profile is different from a parabolic profile due to the slope of the wall. Since the walls of the channel are made of polymer gels, the walls are relatively smooth; the maximum roughness (difference between maximum and minimum height) is approximately

![]() $0.5~{\rm\mu}\text{m}$

over an area of

$0.5~{\rm\mu}\text{m}$

over an area of

![]() $0.5~\text{mm}\times 0.5~\text{mm}$

for the soft wall. However, the roughness scaled by the height of the microchannel, which is approximately 0.2 %, is relatively large compared with that in large pipes and in wind tunnels where noise-free experiments on turbulence are carried out.

$0.5~\text{mm}\times 0.5~\text{mm}$

for the soft wall. However, the roughness scaled by the height of the microchannel, which is approximately 0.2 %, is relatively large compared with that in large pipes and in wind tunnels where noise-free experiments on turbulence are carried out.

Micro particle image velocimetry (Micro PIV) has been used extensively for characterising flows in microfluidic devices. In these measurements, images of the microfluidic chip are usually captured from above, resulting in velocities being averaged over the height (smallest dimension) of the microchannel. In the present experiments, it is necessary to determine the variations in the mean and fluctuating velocities along the height of the microchannel. This dimension is typically very small; in our experiments, even after the channel expands under an applied pressure gradient, the channel height (smallest dimension) is only

![]() $200{-}300~{\rm\mu}\text{m}$

. The seed particles used for velocity tracking need to be at most

$200{-}300~{\rm\mu}\text{m}$

. The seed particles used for velocity tracking need to be at most

![]() $2{-}3~{\rm\mu}\text{m}$

in diameter, smaller than the microchannel height by two orders of magnitude, for accurate velocity measurements. It is necessary to obtain a spatial resolution of the order of

$2{-}3~{\rm\mu}\text{m}$

in diameter, smaller than the microchannel height by two orders of magnitude, for accurate velocity measurements. It is necessary to obtain a spatial resolution of the order of

![]() $10~{\rm\mu}\text{m}$

in order to track these particles accurately. The laser sheet used in the experiments has to be sufficiently thin, much smaller than the spanwise width of the microchannel which is 1.5 mm, in order to obtain local measurements and to avoid averaging in the spanwise direction. In our experiments, the laser sheet is confined to a width of 0.2 mm at the central plane along the spanwise direction. It is also necessary to use high-speed imaging, since instability occurs when the mean velocity in the microchannel is

$10~{\rm\mu}\text{m}$

in order to track these particles accurately. The laser sheet used in the experiments has to be sufficiently thin, much smaller than the spanwise width of the microchannel which is 1.5 mm, in order to obtain local measurements and to avoid averaging in the spanwise direction. In our experiments, the laser sheet is confined to a width of 0.2 mm at the central plane along the spanwise direction. It is also necessary to use high-speed imaging, since instability occurs when the mean velocity in the microchannel is

![]() $1~\text{m}~\text{s}^{-1}$

or more.

$1~\text{m}~\text{s}^{-1}$

or more.

Wall motion is also difficult to measure experimentally for multiple reasons. Previous linear stability studies (Shankar & Kumaran Reference Shankar and Kumaran2001a

, Reference Shankar and Kumaran2002) indicate that for the most unstable ‘wall modes’, the normal displacement of the wall is zero in the leading approximation in an asymptotic expansion in the parameter

![]() $\mathit{Re}^{-1/3}$

, where

$\mathit{Re}^{-1/3}$

, where

![]() $\mathit{Re}$

is the Reynolds number. A weakly nonlinear analysis (Chokshi & Kumaran Reference Chokshi and Kumaran2009) found that the wall mode instability is supercritical, and the transition amplitude is typically small, of the order of

$\mathit{Re}$

is the Reynolds number. A weakly nonlinear analysis (Chokshi & Kumaran Reference Chokshi and Kumaran2009) found that the wall mode instability is supercritical, and the transition amplitude is typically small, of the order of

![]() $10^{-3}\sqrt{\mathit{Re }-\mathit{ Re }_{t}}$

times the channel height close to transition for the parameter values used here, where

$10^{-3}\sqrt{\mathit{Re }-\mathit{ Re }_{t}}$

times the channel height close to transition for the parameter values used here, where

![]() $\mathit{Re}_{t}$

is the transition Reynolds number. This would suggest that perpendicular wall motion will be of the order of microns when

$\mathit{Re}_{t}$

is the transition Reynolds number. This would suggest that perpendicular wall motion will be of the order of microns when

![]() $\mathit{Re}-\mathit{Re}_{t}\sim 100$

; wall displacement of such small magnitude is difficult to measure. Previous experiments (Verma & Kumaran Reference Verma and Kumaran2012, Reference Verma and Kumaran2013) found no discernible wall motion perpendicular to the interface, though wall motion parallel to the interface was inferred by laser scattering off beads embedded in the soft wall. The displacement parallel to the surface, due to the stress exerted by the fluid, is of the order of

$\mathit{Re}-\mathit{Re}_{t}\sim 100$

; wall displacement of such small magnitude is difficult to measure. Previous experiments (Verma & Kumaran Reference Verma and Kumaran2012, Reference Verma and Kumaran2013) found no discernible wall motion perpendicular to the interface, though wall motion parallel to the interface was inferred by laser scattering off beads embedded in the soft wall. The displacement parallel to the surface, due to the stress exerted by the fluid, is of the order of

![]() $5{-}10~{\rm\mu}\text{m}$

for the flow parameters used in the experiments, and so it is necessary to use high magnification to detect these displacements. Another issue is the time resolution required for the detection of wall motion. Linear stability studies (Shankar & Kumaran Reference Shankar and Kumaran2001a

, Reference Shankar and Kumaran2002) predict that the frequency of perturbations at transition is of the order of

$5{-}10~{\rm\mu}\text{m}$

for the flow parameters used in the experiments, and so it is necessary to use high magnification to detect these displacements. Another issue is the time resolution required for the detection of wall motion. Linear stability studies (Shankar & Kumaran Reference Shankar and Kumaran2001a

, Reference Shankar and Kumaran2002) predict that the frequency of perturbations at transition is of the order of

![]() $10^{4}{-}10^{5}~\text{Hz}$

. Such high frequencies are also very difficult to detect by direct imaging techniques. Here, we use direct imaging of dye-marked spots on the fluid–wall interface to detect low-frequency wall motion along the plane parallel to the fluid–wall interface, in order to determine wall displacement due to the fluid stress as well as low-frequency wall motion after transition.

$10^{4}{-}10^{5}~\text{Hz}$

. Such high frequencies are also very difficult to detect by direct imaging techniques. Here, we use direct imaging of dye-marked spots on the fluid–wall interface to detect low-frequency wall motion along the plane parallel to the fluid–wall interface, in order to determine wall displacement due to the fluid stress as well as low-frequency wall motion after transition.

The experimental methods developed and used here are discussed in § 2, and the experimental results for both the fluid velocity and the wall motion are provided in § 3. The important conclusions are discussed in § 4.

2. Experimental methods

2.1. Channel fabrication

The microchannels of height

![]() $160~{\rm\mu}\text{m}$

were fabricated using a modification of the procedure of Verma & Kumaran (Reference Verma and Kumaran2013). Due to limitations on the mechanical pressure that could be applied across these channels on account of the bonding strength, the maximum Reynolds number that could be attained was in the range of 400–500. It was not possible to validate the imaging and image analysis procedure for the turbulent velocity fluctuations in the microchannel with hard walls, since the transition Reynolds number of 1200 is not attainable in the microchannel. Therefore, channels with height 1.52 mm and width 1.5 cm were fabricated using a different procedure but with the same optical set-up (apart from the difference in magnification of a factor of 10) in order to validate the procedure for measuring the turbulent velocity fluctuations, as discussed in the Appendix. The experimental results for the mean velocity, the streamwise and wall-normal root mean square of the fluctuating velocities and the Reynolds stress were found to be in agreement, to within the experimental errors, with direct numerical simulation (DNS) channel flow simulations at a Reynolds number of 3500. This validates the experimental procedure for the velocity measurements discussed in § 2.4. The turbulence measurements in the Appendix, which were carried out in a rigid-walled channel, also provide a context for analysing the similarities and differences between rigid-wall turbulence and the flow after transition in the present system.

$160~{\rm\mu}\text{m}$

were fabricated using a modification of the procedure of Verma & Kumaran (Reference Verma and Kumaran2013). Due to limitations on the mechanical pressure that could be applied across these channels on account of the bonding strength, the maximum Reynolds number that could be attained was in the range of 400–500. It was not possible to validate the imaging and image analysis procedure for the turbulent velocity fluctuations in the microchannel with hard walls, since the transition Reynolds number of 1200 is not attainable in the microchannel. Therefore, channels with height 1.52 mm and width 1.5 cm were fabricated using a different procedure but with the same optical set-up (apart from the difference in magnification of a factor of 10) in order to validate the procedure for measuring the turbulent velocity fluctuations, as discussed in the Appendix. The experimental results for the mean velocity, the streamwise and wall-normal root mean square of the fluctuating velocities and the Reynolds stress were found to be in agreement, to within the experimental errors, with direct numerical simulation (DNS) channel flow simulations at a Reynolds number of 3500. This validates the experimental procedure for the velocity measurements discussed in § 2.4. The turbulence measurements in the Appendix, which were carried out in a rigid-walled channel, also provide a context for analysing the similarities and differences between rigid-wall turbulence and the flow after transition in the present system.

Figure 1. Schematics of the top views of the two different microchannel configurations used (a,b), the channel cross-section in the absence of flow (c) and the channel cross-section in the presence of flow (d), showing the deformation of the soft part. The shaded portions in (a,b) are the regions where the bottom wall is soft. The

![]() $y$

and

$y$

and

![]() $z$

coordinates for the wall-normal and spanwise directions are shown in (d).

$z$

coordinates for the wall-normal and spanwise directions are shown in (d).

The rectangular microchannels of dimensions

![]() $160~{\rm\mu}\text{m}$

height, 1.5 mm width and approximately 40 mm length were fabricated in cross-linked PDMS (polydimethyl-siloxane) gels (Sylgard 184 silicone elastomer kit from Dow Corning) as shown in figure 1. The channel consists of two sections, the upstream development section of length approximately 1 cm to attenuate disturbances at the inlet and a deformable test section of length approximately 3 cm where the velocities are measured. In the development section, all four walls are fabricated using 10 % cross-linker catalyst concentration, as prescribed for the Sylgard 184 kit, which results in a shear modulus of approximately 0.55 MPa. In the test section, three of the walls are made of hard PDMS of shear modulus 0.55 MPa, while the fourth wall is made of soft PDMS with a lower elasticity modulus, by decreasing the catalyst concentration during the fabrication process. Two different catalyst concentrations, 1.75 % and 2 %, were used in the experiments, and the elasticity moduli for these gels are given in table 1. Soft walls with four different shear moduli were used in the earlier study of Verma & Kumaran (Reference Verma and Kumaran2013) on the transition in a soft-walled channel of height

$160~{\rm\mu}\text{m}$

height, 1.5 mm width and approximately 40 mm length were fabricated in cross-linked PDMS (polydimethyl-siloxane) gels (Sylgard 184 silicone elastomer kit from Dow Corning) as shown in figure 1. The channel consists of two sections, the upstream development section of length approximately 1 cm to attenuate disturbances at the inlet and a deformable test section of length approximately 3 cm where the velocities are measured. In the development section, all four walls are fabricated using 10 % cross-linker catalyst concentration, as prescribed for the Sylgard 184 kit, which results in a shear modulus of approximately 0.55 MPa. In the test section, three of the walls are made of hard PDMS of shear modulus 0.55 MPa, while the fourth wall is made of soft PDMS with a lower elasticity modulus, by decreasing the catalyst concentration during the fabrication process. Two different catalyst concentrations, 1.75 % and 2 %, were used in the experiments, and the elasticity moduli for these gels are given in table 1. Soft walls with four different shear moduli were used in the earlier study of Verma & Kumaran (Reference Verma and Kumaran2013) on the transition in a soft-walled channel of height

![]() $160~{\rm\mu}\text{m}$

. The transition Reynolds numbers were

$160~{\rm\mu}\text{m}$

. The transition Reynolds numbers were

![]() $Re=250$

for the wall with shear modulus 18 kPa,

$Re=250$

for the wall with shear modulus 18 kPa,

![]() $Re=332$

for the wall with shear modulus 26 kPa,

$Re=332$

for the wall with shear modulus 26 kPa,

![]() $Re=378$

for the wall with shear modulus 37 kPa, and there was no transition for

$Re=378$

for the wall with shear modulus 37 kPa, and there was no transition for

![]() $Re<422$

for the wall with 54 kPa. There is an experimental limitation that the maximum Reynolds number that can be repeatedly achieved is approximately 400 before there is mechanical failure of the joints. Therefore, we were not able to observe turbulence for the soft wall with shear modulus 54 kPa. For the soft wall with shear modulus 37 kPa, the range of Reynolds numbers for which the flow is unstable, 378–400, is too small to be able to draw conclusions about the variation of the flow properties with Reynolds number. Therefore, we have studied the two lower shear moduli for which there is a sufficient range of Reynolds numbers over which the flow is turbulent.

$Re<422$

for the wall with 54 kPa. There is an experimental limitation that the maximum Reynolds number that can be repeatedly achieved is approximately 400 before there is mechanical failure of the joints. Therefore, we were not able to observe turbulence for the soft wall with shear modulus 54 kPa. For the soft wall with shear modulus 37 kPa, the range of Reynolds numbers for which the flow is unstable, 378–400, is too small to be able to draw conclusions about the variation of the flow properties with Reynolds number. Therefore, we have studied the two lower shear moduli for which there is a sufficient range of Reynolds numbers over which the flow is turbulent.

Table 1. The shear modulus

![]() $G$

, compression modulus

$G$

, compression modulus

![]() $K$

, Youngs modulus

$K$

, Youngs modulus

![]() $E$

and Poisson ratio

$E$

and Poisson ratio

![]() ${\it\nu}$

for the gels with catalyst concentrations of 1.75 % and 2 % used for the soft wall.

${\it\nu}$

for the gels with catalyst concentrations of 1.75 % and 2 % used for the soft wall.

Two different designs for the channel inlet manifolds were used in the experiments. The first is the Y-inlet, whose top view is shown in figure 1(a), where the flow rates in the two inlets are equal. In this design, two different fluids can be pumped into the two different inlets, and the mixing can be visually monitored. The two inlets are arranged symmetrically with equal widths. The second design is the split inlet (figure 1 b) with a central inlet of width 0.3 mm and two outer inlets of width 0.6 mm converging to a microchannel of width 1.5 mm. This is used to inject a dye stream at the centre of the channel and observe the breakup of the dye stream when there is a transition. In this case, the flow rates in the central channel and outer channels are maintained at the ratio 1:4, so that the velocities of these individual streams are equal at the entrance to the development section. Although the velocity profile at the inlet to the development section does depend on the inlet manifold, it has been verified (Verma & Kumaran Reference Verma and Kumaran2013) that the velocity profiles downstream in the test section do not depend on the specific type of inlet used. The split inlet was used in most of the experiments conducted here.

2.2. Experimental set-up

For reference, we consider a coordinate system where the

![]() $x$

axis is along the length of the channel, the

$x$

axis is along the length of the channel, the

![]() $z$

axis is in the spanwise direction with origin at the central plane and the

$z$

axis is in the spanwise direction with origin at the central plane and the

![]() $y$

axis is directed vertically upward from the soft wall across the height (smallest dimension) of the channel, as shown in figure 1(d). The channel is fixed on an optical breadboard of dimensions

$y$

axis is directed vertically upward from the soft wall across the height (smallest dimension) of the channel, as shown in figure 1(d). The channel is fixed on an optical breadboard of dimensions

![]() $1.2~\text{m}\times 0.9~\text{m}$

mounted on a frame with levelling screws from Holmarc Opto-Mechatronics Pvt. Ltd, Kochi, which has standard M6 tapped levelling screws on a 25 mm grid. At the bottom of the mounting assembly for the microchannel is a motorised linear translation stage with a maximum of 150 mm travel, 1 mm pitch screw driven by a stepper motor with

$1.2~\text{m}\times 0.9~\text{m}$

mounted on a frame with levelling screws from Holmarc Opto-Mechatronics Pvt. Ltd, Kochi, which has standard M6 tapped levelling screws on a 25 mm grid. At the bottom of the mounting assembly for the microchannel is a motorised linear translation stage with a maximum of 150 mm travel, 1 mm pitch screw driven by a stepper motor with

![]() $1.8^{\circ }$

steps in the

$1.8^{\circ }$

steps in the

![]() $x$

(flow) direction. The motor has a programmable control unit with a maximum speed of

$x$

(flow) direction. The motor has a programmable control unit with a maximum speed of

![]() $3.125~\text{mm}~\text{s}^{-1}$

. Above this is fixed a manual linear translation stage with maximum travel of 25 mm in the spanwise

$3.125~\text{mm}~\text{s}^{-1}$

. Above this is fixed a manual linear translation stage with maximum travel of 25 mm in the spanwise

![]() $z$

direction for positioning of the microchannel. Above this are two goniometers which permit rotation of the stage by

$z$

direction for positioning of the microchannel. Above this are two goniometers which permit rotation of the stage by

![]() $\pm 10^{\circ }$

about the

$\pm 10^{\circ }$

about the

![]() $z$

and

$z$

and

![]() $x$

axes respectively. A plate of dimension

$x$

axes respectively. A plate of dimension

![]() $10~\text{cm}\times 5~\text{cm}$

is fixed on top of the goniometer, and the microchannel is taped onto the stage.

$10~\text{cm}\times 5~\text{cm}$

is fixed on top of the goniometer, and the microchannel is taped onto the stage.

Figure 2. The configuration for imaging the channel from above (a) and from the side (b).

Two different configurations are used for acquiring images of the channel. For the dye-stream and wall motion experiments, the configuration shown in figure 2(a) is used to take images in the

![]() $x{-}z$

plane from above the channel. A Navitar zoom tube with

$x{-}z$

plane from above the channel. A Navitar zoom tube with

![]() $48\times$

magnification is connected to a Motion Pro HS-4 camera with a maximum framing rate of 1000 Hz and resolution of

$48\times$

magnification is connected to a Motion Pro HS-4 camera with a maximum framing rate of 1000 Hz and resolution of

![]() $512\times 512~\text{pixels}$

with optical axis along the

$512\times 512~\text{pixels}$

with optical axis along the

![]() $y$

direction. Lighting for the channel is provided from below using an MI 150 high-intensity illuminator from Edmund Optics, where the illumination is delivered using an optic fibre cable through a hole carved at the bottom of the mounting plate. For the particle image velocimetry (PIV) measurements and for measurements of the channel deformation, the configuration shown in figure 2(b) is used. A Navitar

$y$

direction. Lighting for the channel is provided from below using an MI 150 high-intensity illuminator from Edmund Optics, where the illumination is delivered using an optic fibre cable through a hole carved at the bottom of the mounting plate. For the particle image velocimetry (PIV) measurements and for measurements of the channel deformation, the configuration shown in figure 2(b) is used. A Navitar

![]() $48\times$

zoom tube is attached to the camera to provide adequate magnification. The camera and zoom tube assembly for capturing the images is aligned horizontally with optical axis along the

$48\times$

zoom tube is attached to the camera to provide adequate magnification. The camera and zoom tube assembly for capturing the images is aligned horizontally with optical axis along the

![]() $z$

direction for capturing images of the flow from the side. In all cases, the flow is driven through the two inlets by NE-1000 (New Era) syringe pumps which are not placed on the breadboard to avoid disturbances.

$z$

direction for capturing images of the flow from the side. In all cases, the flow is driven through the two inlets by NE-1000 (New Era) syringe pumps which are not placed on the breadboard to avoid disturbances.

In the experiments, it is observed that the channel deforms in the test section when there is a pressure difference between the inlet and the outlet (Gervais et al.

Reference Gervais, El-Ali, Guntherb and Jensen2006; Ozsun et al.

Reference Ozsun, Yakhot and Ekinci2013). This wall deformation significantly affects even the laminar velocity profile, and so it is important to characterise this accurately. Since the top and sidewalls are rigid, there is no deformation of these walls. The bottom wall deforms as shown in figure 1(d), with the maximum deformation along the centreline in the spanwise direction. The maximum height along the central plane varies with streamwise location, as shown by the images in figure 3 captured from the side using the configuration in figure 2(b). There is very little deformation in the development section for

![]() $x<0$

where all four walls are made of hard gel. When there is flow (figure 3

b,d), there is significant deformation of the bottom soft wall in the test section. The channel height first increases due to the high pressure at the entrance of the soft section and then decreases with downstream distance as the pressure decreases. In figure 3(c,d), it is observed that there is a small increase in the channel height at the outlet when the soft wall is made of shear modulus 18 kPa. This imperfection is caused by the very low catalyst concentration, and the consequent higher rate of evaporation of solvent at the edge of the microchannel. In order to avoid artefacts due to this expansion at the outlet, all measurements are taken for

$x<0$

where all four walls are made of hard gel. When there is flow (figure 3

b,d), there is significant deformation of the bottom soft wall in the test section. The channel height first increases due to the high pressure at the entrance of the soft section and then decreases with downstream distance as the pressure decreases. In figure 3(c,d), it is observed that there is a small increase in the channel height at the outlet when the soft wall is made of shear modulus 18 kPa. This imperfection is caused by the very low catalyst concentration, and the consequent higher rate of evaporation of solvent at the edge of the microchannel. In order to avoid artefacts due to this expansion at the outlet, all measurements are taken for

![]() $x\leqslant 2.4~\text{cm}$

upstream of the expansion at the outlet, as shown in figure 3(c,d).

$x\leqslant 2.4~\text{cm}$

upstream of the expansion at the outlet, as shown in figure 3(c,d).

Figure 3. Images from the side (using the camera in figure 2

b) of the undeformed microchannel (a,c) and the deformed microchannel when there is a flow with Reynolds number 277 (b,d) for microchannels with soft surfaces made of gel having shear modulus 26 kPa (a,b) and 18 kPa (c,d). The location

![]() $x=0$

is at the joint between the hard and soft sections. The solid rectangles in each image show the locations where the velocity is measured using PIV.

$x=0$

is at the joint between the hard and soft sections. The solid rectangles in each image show the locations where the velocity is measured using PIV.

The deformed cross-section of the microchannel and the variation in the channel deformation along the length are reconstructed from images taken from the side, as shown in figure 2(b), using Autodesk Inventor Professional 2013 software. These shapes are then used in the ANSYS FLUENT computational fluid dynamics package in order to determine the velocity profile and the pressure in the deformed microchannel for a laminar flow (Verma & Kumaran Reference Verma and Kumaran2013, Reference Verma and Kumaran2015). The detailed procedure is as follows. Wall deformation is measured using images in the

![]() $x{-}y$

plane using the configuration in figure 2(b) from the side for each value of the Reynolds number. Figure 3(a,c) shows the side view in the absence of flow, while figure 3(b,d) shows the side view when a pressure gradient is applied and the Reynolds number is 277. From the outline shown in figure 3(b), the maximum channel height at different downstream locations is determined. The channel is reconstructed using Autodesk Inventor Professional 2013 software, as shown by the side view in figure 4(a) and the cross sections at different downstream locations in figure 4(b), for each value of the Reynolds number. The channel geometry is reconstructed using a symmetric cubic spline fit for the bottom wall shape at each downstream location, using the locations of the points A, D and E in figure 1(d), and the condition that the slope is zero at point E, as shown in figure 4. The channel geometry thus generated is used for determining the laminar velocity profiles by solving the incompressible Navier–Stokes equations with no-slip boundary conditions at the walls using the ANSYS FLUENT computational fluid dynamics package. It should be noted that the simulation procedure cannot capture turbulent velocity profiles, because no turbulence model is used, and it also cannot be used to study the effects of wall motion. The simulations are used exclusively for validating the experimental results for the laminar velocity profile at low Reynolds number, and for detecting whether there is a departure from the laminar profile at transition.

$x{-}y$

plane using the configuration in figure 2(b) from the side for each value of the Reynolds number. Figure 3(a,c) shows the side view in the absence of flow, while figure 3(b,d) shows the side view when a pressure gradient is applied and the Reynolds number is 277. From the outline shown in figure 3(b), the maximum channel height at different downstream locations is determined. The channel is reconstructed using Autodesk Inventor Professional 2013 software, as shown by the side view in figure 4(a) and the cross sections at different downstream locations in figure 4(b), for each value of the Reynolds number. The channel geometry is reconstructed using a symmetric cubic spline fit for the bottom wall shape at each downstream location, using the locations of the points A, D and E in figure 1(d), and the condition that the slope is zero at point E, as shown in figure 4. The channel geometry thus generated is used for determining the laminar velocity profiles by solving the incompressible Navier–Stokes equations with no-slip boundary conditions at the walls using the ANSYS FLUENT computational fluid dynamics package. It should be noted that the simulation procedure cannot capture turbulent velocity profiles, because no turbulence model is used, and it also cannot be used to study the effects of wall motion. The simulations are used exclusively for validating the experimental results for the laminar velocity profile at low Reynolds number, and for detecting whether there is a departure from the laminar profile at transition.

Figure 4. The side view (a) and the cross-sectional view at different downstream locations (b) of the deformed microchannel reconstructed from the image in figure 3(b).

In the experiments, the level of disturbance in the laminar flow is relatively large. This is because the inlet conditions cannot be as precisely controlled as those in large wind tunnels. As shown in figure 2, the fluid enters from two syringe pumps through silicone tubing and two pipette tips vertically perpendicular to the microchannel, and then it changes direction by

![]() $90^{\circ }$

and travels horizontally along the microchannel. Further, from figure 1, the inlet consists of two or three streams which converge into a single stream. Due to these, there are relatively large fluctuations in the fluid velocity even in the laminar flow. The maximum of the root mean square of the streamwise velocity fluctuation is approximately 8 % of the maximum velocity, while the maximum root mean square of the cross-stream velocity fluctuations is approximately 1 % of the maximum velocity. Inlet manifolds of the type used here are common in microfluidics, and in such manifolds it is difficult to control the inlet conditions precisely. The level of disturbances might be decreased if the fluid were to enter parallel to the microchannel. However, such a manifold was not possible to fabricate because it requires the inlet to be placed at the joint between the PDMS stamp and the soft bottom surface; inlets placed at the joint result in debonding and mechanical failure due to the pressure exerted and the deformation of the soft surface. Even though there is a development section of 1 cm length following the inlet for flow development to take place, this is not adequate to damp out all of the disturbances. It is difficult to make microchannels with total length greater than the present

$90^{\circ }$

and travels horizontally along the microchannel. Further, from figure 1, the inlet consists of two or three streams which converge into a single stream. Due to these, there are relatively large fluctuations in the fluid velocity even in the laminar flow. The maximum of the root mean square of the streamwise velocity fluctuation is approximately 8 % of the maximum velocity, while the maximum root mean square of the cross-stream velocity fluctuations is approximately 1 % of the maximum velocity. Inlet manifolds of the type used here are common in microfluidics, and in such manifolds it is difficult to control the inlet conditions precisely. The level of disturbances might be decreased if the fluid were to enter parallel to the microchannel. However, such a manifold was not possible to fabricate because it requires the inlet to be placed at the joint between the PDMS stamp and the soft bottom surface; inlets placed at the joint result in debonding and mechanical failure due to the pressure exerted and the deformation of the soft surface. Even though there is a development section of 1 cm length following the inlet for flow development to take place, this is not adequate to damp out all of the disturbances. It is difficult to make microchannels with total length greater than the present

![]() ${\sim}4~\text{cm}$

, since these are made by soft lithography on silicon wafers which have a diameter of 3–4 in., and it is not possible to fit a pattern with linear dimension greater than 5 cm. Further advances in fabrication at the microscale are necessary both to fabricate larger patterns and to fabricate an inlet manifold parallel to the microchannel in order to control the level of disturbances. However, as shown in § 3, the level of the fluctuations after transition is much higher than the level of background disturbances, and so transition is clearly discernible in experiments.

${\sim}4~\text{cm}$

, since these are made by soft lithography on silicon wafers which have a diameter of 3–4 in., and it is not possible to fit a pattern with linear dimension greater than 5 cm. Further advances in fabrication at the microscale are necessary both to fabricate larger patterns and to fabricate an inlet manifold parallel to the microchannel in order to control the level of disturbances. However, as shown in § 3, the level of the fluctuations after transition is much higher than the level of background disturbances, and so transition is clearly discernible in experiments.

2.3. Wall displacement

Wall motion is detected using the set-up shown in figure 2(a) by marking the soft wall of the microchannel with dye spots, and then using a camera above the channel to take images of the displacement and the motion of a spot. This provides us with the tangential displacement parallel to the surface of the soft gel. As discussed in § 3, the tangential displacement of the bottom wall due to the shear flow is of the order of

![]() $10~{\rm\mu}\text{m}$

, and the fluctuations in the displacement due to the fluid velocity fluctuations are smaller still, of the order of

$10~{\rm\mu}\text{m}$

, and the fluctuations in the displacement due to the fluid velocity fluctuations are smaller still, of the order of

![]() $1~{\rm\mu}\text{m}$

or less. Therefore, we use a Navitar zoom tube with a magnification of

$1~{\rm\mu}\text{m}$

or less. Therefore, we use a Navitar zoom tube with a magnification of

![]() $48\times$

in order to magnify a spot on the bottom surface such that the total image covers an area of

$48\times$

in order to magnify a spot on the bottom surface such that the total image covers an area of

![]() $180~{\rm\mu}\text{m}\times 180~{\rm\mu}\text{m}$

. Images are recorded on an attached high-speed Red Lake HS-4 Motion Pro Camera, with a maximum framing rate of 1000 f.p.s. and a resolution of

$180~{\rm\mu}\text{m}\times 180~{\rm\mu}\text{m}$

. Images are recorded on an attached high-speed Red Lake HS-4 Motion Pro Camera, with a maximum framing rate of 1000 f.p.s. and a resolution of

![]() $512\times 512~\text{pixels}$

, such that each pixel covers a width of approximately

$512\times 512~\text{pixels}$

, such that each pixel covers a width of approximately

![]() $0.35~{\rm\mu}\text{m}$

at maximum magnification. The displacement of the dye spot between two successive frames is determined from the maximum in the autocorrelation of the intensity matrices between two successive images. In order to increase the accuracy of the displacement measurement, a continuous two-dimensional Gaussian function is fitted to the elements of the autocorrelation matrix about the peak location using a four-point Gaussian fit, and the displacement corresponding to the location of the peak of the Gaussian is determined. The minimum time interval

$0.35~{\rm\mu}\text{m}$

at maximum magnification. The displacement of the dye spot between two successive frames is determined from the maximum in the autocorrelation of the intensity matrices between two successive images. In order to increase the accuracy of the displacement measurement, a continuous two-dimensional Gaussian function is fitted to the elements of the autocorrelation matrix about the peak location using a four-point Gaussian fit, and the displacement corresponding to the location of the peak of the Gaussian is determined. The minimum time interval

![]() ${\rm\Delta}t$

is 1 ms (corresponding to a framing rate of 1000 f.p.s. and a Nyquist frequency of 500 Hz) and the displacements are determined over a time interval of 15 s or over 15 000 frames.

${\rm\Delta}t$

is 1 ms (corresponding to a framing rate of 1000 f.p.s. and a Nyquist frequency of 500 Hz) and the displacements are determined over a time interval of 15 s or over 15 000 frames.

2.4. Fluid velocity measurements

A customised procedure is used for synthesising the seed particles, which need to have a diameter of approximately

![]() $1~{\rm\mu}\text{m}$

for reliable flow tracking (Melling Reference Melling1997). Monodisperse glass beads cheaply available in large quantities could not be used, since the range of diameters

$1~{\rm\mu}\text{m}$

for reliable flow tracking (Melling Reference Melling1997). Monodisperse glass beads cheaply available in large quantities could not be used, since the range of diameters

![]() $8{-}14~{\rm\mu}\text{m}$

is too large for tracking the velocity in a

$8{-}14~{\rm\mu}\text{m}$

is too large for tracking the velocity in a

![]() $160~{\rm\mu}\text{m}$

microchannel. Monodisperse polymer beads of diameter down to

$160~{\rm\mu}\text{m}$

microchannel. Monodisperse polymer beads of diameter down to

![]() $1~{\rm\mu}\text{m}$

are available in small quantities and are expensive. Our procedure, adapted from Lenzmann et al. (Reference Lenzmann, Li, Kitai and Stover1994), is used to synthesise mono-dispersed spherical polymer particles of size approximately

$1~{\rm\mu}\text{m}$

are available in small quantities and are expensive. Our procedure, adapted from Lenzmann et al. (Reference Lenzmann, Li, Kitai and Stover1994), is used to synthesise mono-dispersed spherical polymer particles of size approximately

![]() $2~{\rm\mu}\text{m}$

by dispersion polymerisation of styrene in ethanol solution. The starting reaction mixture is homogeneous, and the formed polystyrene precipitates out as spherical particles stabilised by a steric barrier of solvated stabiliser. The average diameter is

$2~{\rm\mu}\text{m}$

by dispersion polymerisation of styrene in ethanol solution. The starting reaction mixture is homogeneous, and the formed polystyrene precipitates out as spherical particles stabilised by a steric barrier of solvated stabiliser. The average diameter is

![]() $2.12~{\rm\mu}\text{m}$

and the standard deviation of the size distribution is

$2.12~{\rm\mu}\text{m}$

and the standard deviation of the size distribution is

![]() $0.41~{\rm\mu}\text{m}$

. Careful control of the seed particle size in the range of

$0.41~{\rm\mu}\text{m}$

. Careful control of the seed particle size in the range of

![]() $1{-}3~{\rm\mu}\text{m}$

ensures that both particle inertia and Brownian fluctuations are negligible, and the particles follow the fluid streamlines.

$1{-}3~{\rm\mu}\text{m}$

ensures that both particle inertia and Brownian fluctuations are negligible, and the particles follow the fluid streamlines.

The PIV measurements are carried out using the configuration shown in figure 2(b). The LaVision time-resolved PIV system consists of a double-cavity diode-pumped Nd:YLF laser system (laser class 4) from Litron lasers, with a pulse energy of

![]() $2\times 22.25~\text{mJ}$

1000 Hz, an output wavelength of 527 nm, a beam diameter of 3 mm and a maximum frequency of 20 kHz per cavity. The laser beam is deflected through a light arm and expanded by light sheet optics to the desired specifications of approximately 40 mm width in the streamwise and 0.75 mm width in the spanwise direction. The high-speed camera is a Phantom Miro M110 with CMOS sensor, with a resolution of

$2\times 22.25~\text{mJ}$

1000 Hz, an output wavelength of 527 nm, a beam diameter of 3 mm and a maximum frequency of 20 kHz per cavity. The laser beam is deflected through a light arm and expanded by light sheet optics to the desired specifications of approximately 40 mm width in the streamwise and 0.75 mm width in the spanwise direction. The high-speed camera is a Phantom Miro M110 with CMOS sensor, with a resolution of

![]() $1280\times 800~\text{pixels}$

, sensor dimension

$1280\times 800~\text{pixels}$

, sensor dimension

![]() $5.6~\text{mm}\times 16.0~\text{mm}$

, maximum frame rate of 1630 Hz at full resolution, minimum interframe time of 500 ns, 12 bit, 3 GB memory module with Gigabit Ethernet interface. A Navitar

$5.6~\text{mm}\times 16.0~\text{mm}$

, maximum frame rate of 1630 Hz at full resolution, minimum interframe time of 500 ns, 12 bit, 3 GB memory module with Gigabit Ethernet interface. A Navitar

![]() $48\times$

zoom system with 12 mm fine focus and minimum working distance of 37 mm is mounted on the camera with a C-mount adapter. The acquisition system is a standard PIV package from LaVision including PC, PIV control software, frame grabber and programmable timing unit (PTU). The laser light sheet is aligned along the mid-plane in the spanwise (

$48\times$

zoom system with 12 mm fine focus and minimum working distance of 37 mm is mounted on the camera with a C-mount adapter. The acquisition system is a standard PIV package from LaVision including PC, PIV control software, frame grabber and programmable timing unit (PTU). The laser light sheet is aligned along the mid-plane in the spanwise (

![]() $z$

) direction.

$z$

) direction.

In the PIV system, the laser sheet thickness is approximately 0.75 mm, as measured by burning a line in on a piece of burn paper. This is approximately one-half of the width of the microchannel in the spanwise direction; using such a large width would result in averaging of the velocities in the spanwise direction, and it would not be possible to obtain velocities localised to the central plane. In order to restrict the zone of imaging in the spanwise direction, two masking tapes are placed over the microchannel with a gap of 0.2 mm, as shown in figure 5, such that the laser sheet illuminates the channel only between these two masking tapes. Thus, the velocity is averaged only over the central region of width 0.2 mm in the spanwise direction.

Figure 5. Schematic of the top view of the microchannel showing the width of the microchannel and the tapes used to localise the laser sheet in the spanwise direction when used in the configuration in figure 2(b). Images are taken using the zoom tube at three different downstream locations along the length of the microchannel. The zones A, B and C are 1, 1.8 and 2.4 cm downstream from the start of the test section when the soft wall is made of shear modulus 18 kPa, and 1, 1.8 and 2.9 cm from the start of the test section when the soft wall is made of shear modulus 26 kPa.

The velocities are measured at the three downstream locations A, B and C shown in figure 5. The three locations are 1, 1.8 and 2.4 cm downstream of the start of the test section when the soft wall is made with shear modulus 18 kPa, and 1, 1.8 and 2.9 cm when the soft wall is made with shear modulus 26 kPa. It might be expected that the curvature of the bottom wall due to deformation, as shown in figure 1(d), might refract the light from the particles and diminish the quality of the images taken from the side. There is distortion very close to the start of the test section where the deformation is maximum, and so we were not able to determine velocity profiles in this region. However, we have found that at downstream locations greater than 1 cm from the start of the test section, the refractive indices of the PDMS and the water are sufficiently close that there is very little distortion of the images.

For calculating the mean and fluctuating velocities, the microchannel was divided into 20 intervals in the wall-normal (

![]() $y$

) direction, so that each interval was between

$y$

) direction, so that each interval was between

![]() $10$

and

$10$

and

![]() $15~{\rm\mu}\text{m}$

. Velocity vectors were calculated at the centre of each interval, and the statistics were averaged over the streamwise direction. In cases where higher wall resolution is required, we have refined the three intervals close to the wall by dividing each into three. It was not possible to accurately determine the fluctuating velocities within a region of height

$15~{\rm\mu}\text{m}$

. Velocity vectors were calculated at the centre of each interval, and the statistics were averaged over the streamwise direction. In cases where higher wall resolution is required, we have refined the three intervals close to the wall by dividing each into three. It was not possible to accurately determine the fluctuating velocities within a region of height

![]() $10~{\rm\mu}\text{m}$

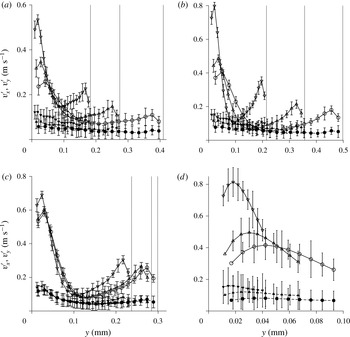

from the wall, due to scattering off the wall, but mean and fluctuating velocities were determined beyond a distance of approximately