Milk fat has a critical role in sensory properties of milk with its wide range of fatty acids and an economical source for producing novel products (e.g. desserts, creamy condiment, dairy creamer), while providing many functional characteristics such as creaming, flavour carrier, creation of a heat transfer medium, layering, shortening etc. (Danviriyakul et al., Reference Danviriyakul, McClements, Decker, Nawar and Chinachoti2002). Converting milk fat into powder form results in high applicability especially in industrial operations and spray drying is widely used for producing the powder form of several kinds of liquid food and/or pharmaceutical materials. In the dairy industry, various kinds of foods and constituents such as milk, cream, butter, lactose, milk protein concentrate, caseinates, cheese, enzyme-modified cheese, yoghurt, whey etc. were converted into powders by spray drying (Koc et al., Reference Koc, Yilmazer, Balkır and Ertekin2010; Augustin et al., Reference Augustin, Sanguansri, Williams and Andrews2012; Erbay and Koca, Reference Erbay and Koca2015; Amighi et al., Reference Amighi, Emam-Djomeh and Madadlou2016; Basu and Athmaselvi, Reference Basu and Athmaselvi2018; Bater et al., Reference Bater, Santos, Galmarini, Gomez-Zavaglia and Chirife2019).

The production and storage properties of high-fat powders differ from other dairy powders. The reconstitution ability and flowability of high-fat powders are relatively low whereas the sensitivity to oxidation is high. Moreover, stickiness problem which results in low yield and quality defects can occur during the spray drying of high-fat powders. One effective solution to overcome these problems is the encapsulation of milk fat by covering the fat with a wall material comprising thin and continuous film properties to insulate the milk fat from the environmental effects (Himmetagaoglu and Erbay, Reference Himmetagaoglu and Erbay2019). While the most important stage in microencapsulation of milk fat is emulsion preparation and its stability, spray drying conditions should also be considered as it is the fundamental process in converting the emulsion into powder form. Therefore, to perform an efficient process and to obtain a high-quality product, the spray drying parameters should be evaluated and optimised (Erbay et al., Reference Erbay, Koca, Kaymak-Ertekin and Ucuncu2015).

There is limited information in the literature on the optimisation of spray drying process in dairy powders (Koc et al., Reference Koc, Yilmazer, Balkır and Ertekin2010; Erbay et al., Reference Erbay, Koca, Kaymak-Ertekin and Ucuncu2015; Amighi et al., Reference Amighi, Emam-Djomeh and Madadlou2016) and no information in cream powder production. The aim of this study was to determine the optimum process conditions for spray drying in the production of microencapsulated cream powder, whose formulation was determined and quality properties were investigated in the previous research published by the authors (Himmetagaoglu et al., Reference Himmetagaoglu, Erbay and Cam2018; Himmetagaoglu and Erbay, Reference Himmetagaoglu and Erbay2019).

Materials and methods

Powder productions

The raw milk used in the present study was provided by a local dairy farm established in Adana, Turkey. The raw milk was preheated to 65°C and the cream with a fat content of 72.5% was obtained by a cream separator (Tulsan, Istanbul, Turkey). The obtained cream was pasteurised at 85°C for 60 s, cooled and stored at −18°C.

An oil-in-water emulsion was prepared (using cream as fat source, maltodextrin (18 DE) and sodium caseinate as wall materials, soy lecithin as emulsifier, sodium phosphate as acidulant, sodium citrate as stabiliser, and calcium carbonate as anti-caking agent) according to the formulation and method described in detail by Himmetagaoglu et al. (Reference Himmetagaoglu, Erbay and Cam2018). Maltodextrin was obtained from Sunar Misir (Adana, Turkey) whereas the other materials were purchased from Sigma (Darmstadt, Germany). After the emulsion preparation, the emulsions were converted into powder by a laboratory-type spray dryer (B-290, BUCHI, Flawil, Switzerland). The feed temperature was 45°C. Briefly, the prepared emulsions set at a total solid content of 25% and microencapsulated cream powders were produced with a fat content of 60%, while the total wall material per total solid content ratio was adjusted to 30%. Moisture, fat, protein, lactose and ash contents of the microencapsulated powders produced in this study were 1.1% ± 0.7, 61.0% ± 1.1, 8.3% ± 0.3, 2.4% ± 0.2 and 0.5% ± 0.1, respectively.

Experimental design, statistical analysis and optimisation

The optimum conditions for the spray drying during the production of microencapsulated cream powder were determined by response surface methodology (RSM). A central composite rotatable design (CCRD) with three factors was prepared. The factors in the optimisation were determined as the inlet spray drying temperature (x 1), the emulsion feed flow rate (x 2) and the aspiration rate (x 3). The levels of the factors were in the range of 150–190°C for the inlet drying temperature, 9–30 ml/min for the feed flow rate, and 50–100% (20.0–38.3 m3/h) for the aspiration rate. During the production experiments, the outlet drying temperatures were varied from 67.0 to 95.1°C. While the process variables were chosen by the literature review and by the properties of the spray dryer used in the study, the levels of the optimisation factors were determined according to the former studies in the literature focused on spray drying or cream powder production (Onwulata et al., Reference Onwulata, Smith and Holsinger1995; Danviriyakul et al., Reference Danviriyakul, McClements, Decker, Nawar and Chinachoti2002; Erbay and Koca, Reference Erbay and Koca2015), and preliminary trial productions.

Multiple regression analysis was used to establish a quadratic model equation for the independent variables. Analysis of variance (ANOVA) was performed to check the significant difference in the models by F-statistic with 95% confidence interval. The assumptions used in ANOVA were validated by the residual analyses with diagnostic plots and case statistics. The objective was to perform the spray drying process with the highest drying yield and to obtain a powder with the highest bulk density, the shortest wetting time, and the lowest surface fat content. All responses were modelled and the obtained models were used to optimise the spray drying process. The desirability function method was performed and the same importance values were appointed to all responses during calculations. The calculations were made using the Design Expert Software (Version 7.0.0, Stat-Ease, 2005) and experimental design used in the present study is given in Table 1.

Table 1. Experimental design and results of response variables for CCRD (x 1: inlet spray drying temperature, x 2: feed flow rate, x 3: aspiration rate)

Analyses

The drying yield, expressed as percentage, was calculated by dividing the dry matter content of the obtained powder collected from the collecting chamber with the dry matter content of the emulsion prepared. By this way, the recovery of solid material during spray drying was evaluated. Bulk densities, wettabilities and surface fat contents of the powder samples were determined by methods explained in Erbay and Koca (Reference Erbay and Koca2015). Measurements were made in quintuplicate for wettability and in triplicates for the others. Additionally, physical properties, free fatty acid composition and morphological properties of microencapsulated cream powder produced at optimum spray drying conditions were determined according to the methods used in Himmetagaoglu and Erbay (Reference Himmetagaoglu and Erbay2019).

Results and discussion

The productions in the experimental design were conducted in random order. There are several quality parameters for food powders and in the present study the responses were selected as drying yield, bulk density, wettability, and surface fat content. Within these responses, drying yield gives information about the efficiency of the process. Converting foodstuff into powder provides a longer shelf-life and less storage space and packaging materials. Bulk density is an important parameter defining the need for packaging materials and storage space. Moreover, food powders are mainly used as food additives industrially. In order to ensure industrial applicability of powders, excellent rehydration/reconstitution properties are required. Due to their low bulk and particle densities, high-fat powders often experience rehydration/reconstitution issues. Therefore, wettability (or wetting time of powder particles), one of the fundamental parameters that gives information about rehydration/reconstitution characteristics of the powder, was included in the optimisation. Finally, surface fat content of powders is a critical factor especially in high-fat powders since it is related with lipid oxidation which is one of the most important causes of detrimental changes and quality loss during powder storage.

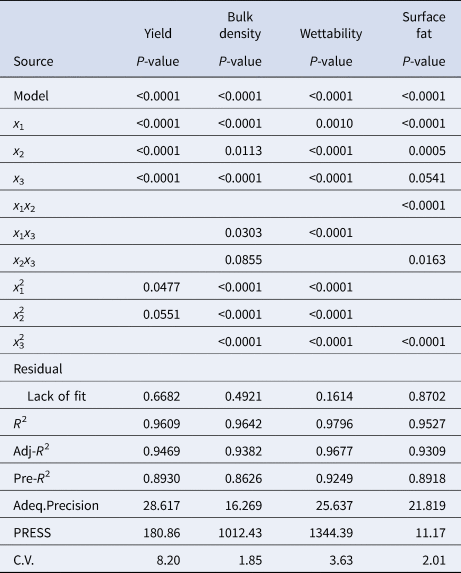

ANOVA was conducted to determine linear, interaction, and quadratic terms for each response. Model parameters with a P-value greater than 0.1 were removed from the models without damaging the model hierarchy. After removing the insignificant factors, the ANOVA results for the reduced model are given in Table 2. The value of R 2 being greater than 0.95 indicates that most of the total variations were explained by the model (R 2 > 0.95). The difference between R 2 and Adj-R 2 being smaller than 3% indicated that the model did not contain statistically insignificant terms. The following values indicate that the accuracy of the polynomial model was statistically appropriate: a difference less than 20% between Pre-R 2 and Adj-R 2, C.V. value less than 10, and Adeq.Precision value greater than 4, as these values for the models were a maximum of 7.56% and 8.20, and the minimum of 16.269, respectively. It was shown that the lack of fit was not significant for any response surface models. The response surface graphics were plotted to investigate the effects of the interaction terms/variables by setting the third variable constant at the central condition (online Supplementary Figs S1–5).

Table 2. ANOVA evaluation for each response variable and coefficients of prediction models in terms of coded factors after removing the insignificant factors (x 1: inlet spray drying temperature, x 2: feed flow rate, x 3: aspiration rate)

According to the drying yield results obtained from the experimental productions at twenty spray drying conditions, drying yield values were obtained in the range of 12.15–42.93% (Table 1) and the variation of drying yield was successfully explained with a linear model (Table 2). Furthermore, the addition of squared terms of inlet temperature and feed flow rate into the linear model improved the model data fit. It is obvious that the increase in the inlet temperature and aspiration rate and the decrease in the feed flow rate resulted in an increase in the drying yield.

Statistical analysis showed that the linear and squared terms of all process variables, and the interaction effects of inlet temperature–aspiration rate and feed flow rate–aspiration rate were significant for the bulk density of microencapsulated cream powder (Table 2). According to the linear terms obtained from the model, increasing the temperature and aspiration rate and decreasing the feed flow rate caused a decrease in the bulk density.

While wettability of the microencapsulated cream powders changed between 115.2 and 203.8 s, surface fat contents varied in the range of 26.20–34.13% (Table 1). Results showed that the linear and squared effects of all process variables and the interaction effect of inlet temperature-aspiration rate were significant for the wettability of powders (Table 2). Besides the linear and squared effects of aspiration rate, the interaction effects of inlet temperature-feed flow rate and feed flow rate-aspiration rate were statistically significant for the surface fat content of the powders (Table 2). With respect to linear terms of the model, the highest impact on surface fat content increase was related to the increase in the inlet drying temperature, followed by feed flow rate.

Desirability functions were created for optimisation for the following criteria: maximum drying yield and bulk density, minimum wettability, and surface fat content. The effects of interaction terms on the desirability function were shown in online Supplementary Figs S6–8. The results of the desirability function method calculated for the spray drying process were: 162.8°C for the inlet temperature, 11.51 ml/min for the feed flow rate, and 72.8% for the aspiration rate. At this condition, the drying yield, bulk density, wettability and surface fat content values were predicted by the model as 36.37%, 269.9 kg/m3, 115.2 s, and 26.2%, respectively and the desirability value was 0.841.

Five production runs were made at the optimum processing conditions for verification of the predicted model. Results of statistical analysis for verification of optimisation of microencapsulated cream powder production are listed in online Supplementary Table S1. No significant differences were found between experimental values and predicted values (P > 0.05). In summary, experimental values and predicted values were found to be very close to each other and the optimum conditions were experimentally validated.

Some physical (water activity, solubility, tapped and particle densities, Hausner ratio, Carr index, colour values) and chemical properties (free fatty acid composition) of powders produced at optimum processing conditions were determined and these are shown in online Supplementary Table S2. Additionally, scanning electron microscopy (SEM) was used to evaluate the morphological properties of powders and SEM micrographs of powder particles were presented in online Supplementary Fig. 9. According to the SEM micrographs, powder particles seemed to be spherical with low agglomeration and surface imperfections (damaged, cracked or fractured powder particles). Moreover, the surfaces of particles (especially larger ones) were not smooth, generally wrinkled which indicated that fat was not dominant on the surface as aimed in the optimisation.

In conclusion, spray drying process conditions were optimised in the production of microencapsulated cream powder using response surface methodology. The powders with the highest bulk density, the shortest wetting time, and the lowest surface fat content with the highest drying yield were produced at 162.8°C inlet drying temperature and 11.51 ml/min feed flow rate with 72.8% aspiration rate.

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1017/S0022029920000795

Acknowledgements

This work was supported by The Scientific and Technological Research Council of Turkey (TUBITAK) [project no: 215O948].