As one of the first modern industrial enterprises, the DuPont chemical company has long been an important case study for business historians, and particularly its rapport with the U.S. federal government.Footnote 1 With the exception of works on the company’s early accounting practices and industrial espionage, the vast majority of scholarship thus focuses on the firm’s mid-nineteenth and twentieth century history.Footnote 2 Located on the Brandywine Creek in northern Delaware, the Eleutherian Mills—or Mills of Liberty in the rough translation from Greek to French to English—played a significant role in the industrial development of the early United States. A study of DuPont’s early years is important because it demonstrates the long-lasting nature of its relationship with federal military institutions. Works that do address E. I. du Pont de Nemours & Co.’s initial formation emphasize the same reasons that the DuPonts themselves sometimes claimed. Their factory would not “serve for war, but for the exercises that prevent war … to the country’s commerce, hunting, the opening up of mountains and canals to public works.”Footnote 3 Was this actually the case? Was the business, and its success, premised on a vast civilian market for gunpowder? The relative lack of studies on the early years of the firm brings these questions to a point: How exactly did DuPont become the preeminent gunpowder company in the early republic? The answer to that question can be found in the dual roles of foreign capital and government contracts. Substantial funds sourced from France, Switzerland, and Saint-Domingue allowed the company to obtain tools and relatively advanced manufacturing techniques from France’s Gunpowder Administration. Access to the halls of power in Washington, DC, through family friend President Thomas Jefferson, allowed the firm to gain a favored position in the American market during the early 1800s vis-à-vis its ability to garner lucrative military contracts.

Well before the firm’s latter history, the establishment of E. I. du Pont de Nemours & Co. sheds light on the nature of state–firm interactions in the early republic. In recent years there has been an engaging discussion on the theory and practice of political economy in this period, and specifically what role, if any, did the federal and state governments play in supporting economic development. One school of thought holds that advances in technology primarily drove industrial development. Networks of highly skilled machinists and inventors received indirect state support through a variety of means, such as patents, tariff protection, and a military interested in promoting technological advances.Footnote 4 The national armory system is a case in point. Skilled laborers frequently moved between the armories and private firms, taking knowledge of replaceable parts manufacture with them. The end result was an American “system of manufactures” that became the forerunner of modern mass production.Footnote 5 In a related argument, another group of scholars sees the emergence of industrialization as the result of a growing consensus in favor of liberal capitalism.Footnote 6 The opening up of foreign markets, limited tariff support, widespread banking, and favorable state legal regimes largely allowed the invisible hand of the market to guide the economy. Finally, a third thread in the historiography argues that economic development was primarily the result of state governments taking an active role in shaping the legal and institutional landscape. Even if the federal government did not always act to secure business interests for ideological and constitutional reasons, the states themselves did so through patronage and crony capitalism.Footnote 7 In their view, private interests were largely successful in capturing public administration for their own ends.

The early history of DuPont suggests that elements of all three historical interpretations were at work, but more importantly demonstrates that the federal government played a central role in developing private military industry. The actions of the state to foster such firms were by no means incompatible with the prevailing of liberal capitalism of the nineteenth century. Within Adam Smith’s anti-mercantilist philosophy was a substantial exception for manufacturers that pertained to national defense.Footnote 8 Relatively liberal economic policies in the early nineteenth century could be both hands-off for most economic sectors, while also embracing a modicum of state support for businesses essential for war. DuPont is just one notable example, and its history is instructive for parsing out a larger trend in the history of American state–firm relations. In forming their gunpowder company, the Du Pont family relied on a trans-Atlantic network to acquire capital and import advanced machinery, they secured favorable contracts for both their gunpowder and woolen ventures, and they benefitted from a national political economy that supported the arms and munitions industries.

DuPont and the federal government had a mutually beneficial relationship during the first two decades of the nineteenth century. For the administrations of the Virginia Dynasty (Jefferson through Monroe), the Mills of Liberty solved the problem of where to obtain an essential good for national defense. Instead of enduring the expense of setting up a state-run factory, as in the case of the armories, or relying on foreign imports, as during the Revolution, DuPont ensured that the federal government received a steady supply of gunpowder as long as the company was supported through periodic peacetime contracts. DuPont, for its part, clearly benefitted from its relationship with the federal government. War Department contracts for gunpowder (and later woolens) played an important role in providing steady revenues for the venture. A loosening of restrictions on gunpowder exports, modest tariffs, patent law, and the prestige of having the civilian market know that it was the principle supplier trusted by the government also aided the firm. Although a private firm, DuPont was essential to the American state and vice versa.

When the du Pont family left France for the United States in 1799, they did so with the intention of creating a vast fortune in their new home. The Coup of 18 Fructidor (September 1797) brought the Jacobins back to power and temporarily placed the family patriarch, Pierre S. Du Pont, in prison. Pierre and his sons, Victor and Eleuthère Irénée, were moderate royalists during the French Revolution, and the recent turn of affairs convinced them that they had a limited future in France.Footnote 9 Like the émigré of the early 1790s, the family had substantial wealth, which aided in their transition to the United States.Footnote 10 Unlike the émigré, they received permission from the ruling Directory to engage in foreign commerce, and could thus liquidate their holdings and transfer their capital out of the country. With passport in hand, the father convinced a number of his friends to become shareholders in the family firm Du Pont de Nemours Père, Fils et Compagnie.Footnote 11 At first, Pierre believed that his company should obtain and improve tramontane land, as numerous other European capitalists had done throughout the 1790s. However, the conditions of the American real estate market soon forced the family to change their plans. Upon hearing of his old friend’s idea to invest in land, Thomas Jefferson warned Du Pont about the “swarms of speculators” and a resulting bubble that was sure to burst.Footnote 12 Du Pont heeded Jefferson’s advice and soon warned his investors that they would be unable to make any money in a land venture. Instead, the family company would have to consider other prospects.

While the Du Pont parent company invested in a number of businesses, such as a New York City commission firm run by Victor, their most successful venture was the decision to invest in a gunpowder mill run by the younger son, Eleuthère Irénée (Figure 1). E. I. du Pont was no stranger to the powder business. During the 1780s, he had been an apprentice to Antoine Lavoisier, the famous chemist in charge of the France’s state-run mill at Essonne.Footnote 13 While working for Lavoisier’s Gunpowder Administration, he acquired knowledge of the latest techniques in saltpeter refinement and mechanized gunpowder production, a science at which the French state-run mills excelled.Footnote 14 Compared to European manufacturing techniques, the American gunpowder industry in the 1790s remained in a primitive state, unable to produce gunpowder in large quantities or of sufficient quality. For example, manufacturers relied on antiquated production methods, such as handworked mortar and pestle, to mix the powder. Knowledge of how to refine calcium nitrate into potassium nitrate (the active ingredient in saltpeter) was little known in the United States, and American technical publications confirm that the introduction of alkaline salts to refine saltpeter was still little-used, and little-understood, in the manufacturing process, even if it had been known in Europe for centuries.Footnote 15

Figure 1 Eleuthère Irénée du Pont de Nemours (1771–1834).

Eleuthère Irénée du Pont de Nemours (1771–1834), Eng. By E. G. Williams & Bro. NY, Engravings, Accession Number 70.182.8 Courtesy of the Hagley Museum and Library.

Given the clear limitations of supply in the American market, the family’s decision to invest in a powder mill should have been an obvious one. Nevertheless, the state of American political economy in the late 1790s made such a venture anything but. From a practical standpoint, such a firm would be hindered as gunpowder was a highly regulated export commodity and received no tariff protection from the government. This, however, was not always the case. In 1790, political economist Tench Coxe estimated that the United States contained twenty-one powder mills that could produce up to 1.25 million pounds per year.Footnote 16 In his 1791 Report on Manufactures, Alexander Hamilton claimed these producers as one of the few industries that had achieved “a considerable degree of maturity.”Footnote 17 However, the health of American powder mills was not to last as the world descended into the wars of the French Revolution.

The decline of the American powder industry was tied to Federalist foreign and trade policy. Beginning in 1794, the Federalists passed legislation that exempted gunpowder from the tariff and, more importantly, prohibited its exportation.Footnote 18 The Washington and Adams administrations believed that it was too dangerous to countenance the munitions trade in a world at war. It was worth sacrificing the special interests of arms producers in order to keep the United States out of the global conflict. Although some merchants certainly smuggled American-made gunpowder out of the country, the federal government was willing to pursue charges against exporters all the way up to the Supreme Court, as they did in the case of U.S. v. La Vengeance (1796).Footnote 19 The effects of Federalist trade policy were apparent by the mid-1790s. Except for a few small powder firms that managed to hang on, domestic producers could not compete with what importations actually arrived from Europe. During the war scare with Great Britain, Coxe now warned, “We shall be exceedingly restrained in our operations … by the want of Gunpowder.”Footnote 20 He estimated the total annual production at two hundred thousand pounds per year, less than a sixth of his estimate half a decade before.Footnote 21 In 1795 an English traveler begged his friends to send him gunpowder as that available in the United States was expensive and of poor quality.Footnote 22

In addition to the crippling legal restrictions on the international powder trade, there were more general concerns regarding the viability of large manufacturing establishments in an agrarian economy. In the Report on Manufactures, Hamilton argued that industrialization was a positive good for the economy. Despite high labor costs, in the short-term, manufacturing could be best supported through export bounties; modest revenue-generating tariffs; and by state-chartered, for-profit corporations such as New Jersey’s Society for Establishing Useful Manufactures (SEUM).Footnote 23 Only in the long run, after the United States achieved parity with Great Britain, could it turn to a more protective mercantilist political economy. Although for-profit corporations became more common as the decade progressed, there was significant political pushback against individuals receiving limited liability for their personal business ventures.Footnote 24 Furthermore, it was not clear that incorporation would work for manufacturing establishments. At the turn of the century, most investment in North America, both foreign and domestic, was either in real estate or commerce, while the SEUM’s textile mills had gone out of business. On the one hand, marine insurance, banks, land, and enslaved persons were the favored holdings of capitalists because these investments offered the highest rates of return with little overall risk. Manufacturing firms, on the other hand, carried a substantial risk as long as Great Britain maintained a comparative advantage in technology and labor costs, as well as the low barriers to trade granted by the 1795 Jay Treaty.Footnote 25

The election of Thomas Jefferson to the presidency in 1800 opened up the possibility that the producers of war material could thrive in the domestic and international markets. National debates over military preparedness in the 1790s led to a semiofficial Republican Party position that appeared well-suited to the interests of manufacturers, particularly the makers of arms and munitions. Jefferson opposed the ban on weapons exports in no uncertain terms: “Our citizens have been always free to make, vend, and export arms: that it is the constant occupation and livelihood of some of them. To suppress their callings, the only means, perhaps of their subsistence, because a War exists in foreign and distant countries, in which we have no concern, would scarcely be expected.”Footnote 26 After the 1794 war scare and the resulting treaty with Britain, the Republicans took this opportunity to align their policy of commercial discrimination with the interests of domestic manufacturers.Footnote 27 James Madison announced in a widely distributed pamphlet that, contrary to the accusations of Federalists, his party was more than willing to “fill our magazines” with gunpowder as a necessary precaution.Footnote 28 After becoming president, Jefferson informed Congress that his armament policy would emphasize a competitive domestic market.Footnote 29 Numerous private producers, acting in their own self-interest, with moderate tariff protection and a vibrant export market awaiting their wares, could compete among themselves to bring down the cost of military goods for the federal government. When the Federalist tariff exemption and ban on weapons exports expired at the end of 1801, no Congressional Republican thought to reintroduce the measures. The revolution in America’s political economy of war was profound. With rhetorical flourish, Jefferson explained that by relying on private producers the government could purchase “silver guns cheaper than they can make iron ones.”Footnote 30 Far from opposing manufacturing in American political economy, Jefferson believed that the introduction of labor-saving machines to produce goods in rural areas was a positive development.Footnote 31 Gunpowder mills situated outside urban centers, such as that built by the Du Ponts, would have the added benefit of playing an essential role in the country’s national defense. After Jefferson’s election, the Du Ponts understood that they could capitalize on the policies of the incoming Republican administration and Congress by deciding to invest parent company funds into a gunpowder mill.

On April 21, 1801, E. I. du Pont drew up Articles of Incorporation in Paris that would allow him to raise substantial capital from sources outside the family without having to petition the Delaware legislature for an act of incorporation or rely on American investors.Footnote 32 Compared to the United States in the late eighteenth century, France had relatively sophisticated corporate law.Footnote 33 The société en commandite simple, essentially a limited liability partnership with aspects of a joint stock company, was a favored legal institution in ancien régime France as it allowed the nobility to invest in commercial ventures without threatening their social standing. For the Du Ponts, organizing the firm in this manner offered them the benefits of raising outside funds while ensuring that the assets of their investors would receive some insulation from American lawsuits should the company fail. E. I. du Pont estimated that a competitive mill in the American market would require an initial capitalization of $36,000. At $2,000 per share, the family invested $20,000 of their company’s funds into the firm in order to maintain control over the venture. Under the proposed partnership, they would still need to raise $16,000 from investors to make up the difference. Thus, in January 1801, E. I. du Pont and his older brother, Victor, returned to France to sell the remaining shares and purchase European manufactured machinery for the mill. The brothers were aided in these goals by their father’s friends and investors in the parent company and by their contacts within the French military bureaucracy.

The pitch to potential investors emphasized the comparative advantage that a well-capitalized firm, utilizing the most advanced French technology, would have in the American market. Such a firm would easily be able to garner lucrative government contracts. In a memorandum distributed among potential investors, E. I. du Pont estimated that there were only two or three powder mills then operational in the United States. These few firms made poor quality powder by hand with mortar and pestle. Alternatively, “a manufacture in which nearly all the work is done by machinery” would “count on a high price and a sure market for its product” by “supplying … the Government for the Navy, for the Army, and for the Forts which are now nearly empty.”Footnote 34 Although he knew there was no guarantee, the military’s demand for powder would surely lead to numerous contracts and easy profits. In this vein, Victor du Pont wrote to the Swiss banker Louis Necker de Germany, requesting an investment and assuring him that the gunpowder mill would be “under the protection of the United States government and with the assurance of supplying it.”Footnote 35 Promises like these, even if there was no guarantee of a federal contract, convinced Necker to loan nearly $10,000 to the Du Ponts and to become a shareholder in the mill. As he later admitted, it was the family’s “friendly relations with Mr. Jefferson” that convinced him to invest.Footnote 36 Based on similar beliefs about the firm’s prospects, other investors consigned goods, or paid in specie so that the Du Ponts could readily purchase French manufactured tools and machinery.Footnote 37 With these three shares supplied for, five remained of the original eighteen. Even though Necker’s loan covered the necessary operating expenses stated in the partnership agreement, there was still room for 5/18 of the company to be had at the ground floor price.Footnote 38 As evidenced by the favorable reaction of the French and Swiss investors, the promise of federal protection was an essential component that convinced these capitalists to invest in a risky firm that had a high chance of complete failure given one stray spark.

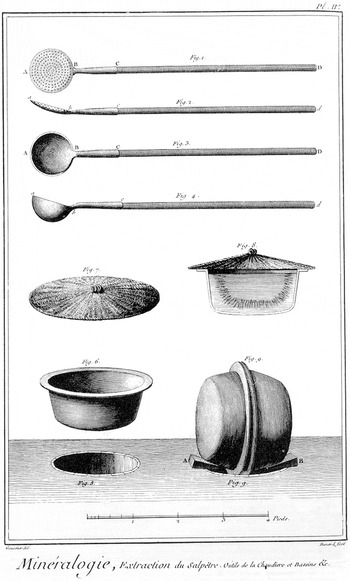

In addition to the European investors, the family’s assurances of state support allowed them to acquire advanced technology from France’s Gunpowder Administration. Like other American industrial companies in the early republic, the firm relied on foreign technology and skilled labor to produce its goods. Unlike other companies, E. I. du Pont de Nemours & Co.’s easy ability to obtain advanced technology directly from the French government stood it in stark contrast to firms that relied on pirated British trade secrets.Footnote 39 Like the investors, the correspondence between E. I. du Pont and the administrators of France’s Gunpowder Administration reveal that key individuals within the French military bureaucracy aided du Pont because of his assurances of “an enormous market and the protection of the Government.”Footnote 40 The superintendent of the state-run Essonne mill was more than willing to help him find skilled laborers and duplicate the machinery at Essonne because the United States was “in rivalry” with Great Britain.Footnote 41 Geo-strategic self-interest ruled the day as the enemy of their enemy was their friend. The Gunpowder Administration readily supplied du Pont with whatever he wanted, from technical drawings to skilled laborers and copper tools. The relative importance of such cheap copper for the firm can be seen in the fact that E. I. du Pont estimated that fully one-quarter of the company’s funds would be allocated to purchase these tools and machines.Footnote 42 Had the Federalists, and their Francophobic policies, remained in power after the election of 1800, it is doubtful if the French would have been so forthcoming. The firm’s account book from this period confirms that du Pont was able to obtain all manner of copper machinery from the government’s mills. In summer 1801, he recorded payments at Essonne for casts of the milling stamps and for copper “utensils” to refine saltpeter (Figures 2, 3, and 4).Footnote 43 The potential success of the gunpowder mill, premised on military contracts, was evident to French administrators, who each offered to invest in the factory but at much less than the $2,000 per share.Footnote 44

Figure 2 Perspective view of the interior of the stamping mill.

Encyclopedia of Diderot & d’Alembert Collaborative Translation Project, “Natural History–Mineralogy—Manufacture of Powder.” Originally published as “Histoire naturelle—Minéralogie–Fabrique des Poudres,” Encyclopédie ou Dictionnaire raisonné des sciences, des arts et des métiers, vol. 6 (plates) (Paris, 1768).

Figure 4 Extraction of saltpeter tools for the boiler and pans.

Encyclopedia of Diderot & d’Alembert Collaborative Translation Project. “Natural History—Saltpetre—Manufacture or Extraction of Saltpetre.” Originally published as “Histoire naturelle—Salpêtre—Fabrique ou extraction du salpêtre,” Encyclopédie ou Dictionnaire raisonné des sciences, des arts et des métiers, vol. 6 (plates) (Paris, 1768).

Although not recognized by American courts, the legal principles of the société en commandite simple signed in Paris determined how DuPont would raise funds in the United States as well. While E. I. du Pont was able to raise the required capitalization of the firm from his father’s Swiss and French investors, there still remained five outstanding shares in the powder mill. In order to sell the remaining shares, they turned to the American capital market. Despite interest shown by several merchants, the Du Ponts ultimately rebuffed them in favor of Francophone capitalists who understood the principles of French limited liability corporations. As Pierre later explained to the shareholders of the parent company, under American law any investor in the firm could be sued for the debts of the whole, and thus it was better to keep the company limited to French-speaking capitalists who understood the principles of limited liability and would not sue to obtain debts beyond what was invested.Footnote 45 Selling their shares to Americans for a profit would be a mistake, he reasoned, as it would increase each individual’s liability for the entire venture.

Fortunately for the Du Ponts, the Francophone expatriate community in Delaware provided a local source of funds and an understanding of the differences between French and American partnership law. Pierre Bauduy, a Saint-Domingue sugar plantation owner who settled in Wilmington during the early phases of the Haitian Revolution (and had obtained American citizenship) provided the firm with a source of capital in the United States.Footnote 46 Like the other shareholders, Bauduy was attracted to the business because he saw the potential of a well-capitalized mill employing the latest technological advances and aided by Jefferson’s policies and patronage.Footnote 47 His purchase of the remaining five shares placed funds toward the physical construction of the millworks along the Brandywine. In 1802 Bauduy estimated that the construction of the Eleutherian Mills would cost approximately $7,000, or nearly 70 percent of the firm’s available cash. Understanding that he was legally liable for all the firm’s debts under U.S. law, Bauduy had, by January 1805, paid over $12,000 to local farmers, artisans, merchants, and laborers to ensure the success of the firm.Footnote 48 Bauduy’s investment allowed the Du Ponts to quickly complete their mill and begin production by the end of the year.Footnote 49 A local source of capital from a trusted investor provided the firm with the ability to conduct business easily on the American side of the Atlantic, just as their French and Swiss capital allowed them to purchase manufactured goods in Europe.

While the firm relied on Francophone sources of capital to begin operations, the company made a concerted push to gain federal contracts. Pierre Du Pont suggested to Thomas Jefferson that the federal government should do business with his son even before DuPont commenced operations. In December 1800, before the results of the contested presidential election were formally decided by the House of Representatives, Du Pont informed Jefferson that his family was about to build a gunpowder factory. The federal government should patronize their mill because it would produce a superior product through advanced technology. Although it might appear that the president would be playing favorites in an open market, Pierre assured him that “Under your presidency, everything will go to the best and the worthiest. And despite, your, our, extremely democratic principles, it will be said that in that sense Jefferson leans towards the aristocracy.—So does the sublime president of the universe.”Footnote 50 Du Pont’s meaning was clear: critics would claim that awarding contracts to his son’s firm was a form of cronyism and partisan patronage. However, the superiority of the product would speak for itself. The following summer, after Jefferson’s inauguration, Du Pont advised the president that the mills would soon be producing powder with technology and machinery that had been “made in France,” which “could hardly be made here.”Footnote 51

While foreign and domestic investments were necessary for the purchase of machinery, the initial labor costs, and the construction of the mills, the Du Ponts still needed to sell gunpowder in the American market to turn a profit. Even though E. I. du Pont quickly developed a network of agents in the major cities along the Eastern seaboard to sell his gunpowder to civilians, his most coveted client was the federal government. By midsummer 1803, Victor and E. I. decided to appeal directly to Thomas Jefferson for a powder contract.Footnote 52 In their letter to the president, they explained that the factory required “significant support to get established” and any contracts for “war munitions,” whether new gunpowder, remanufactured powder, or refined saltpeter, would be mutually beneficial.Footnote 53 Upon receiving their letter, Jefferson forwarded it to Secretary of War Henry Dearborn, and told him, “If the public can with advantage avail themselves of his improvements in that art, it would be to encourage improvement in one of the most essential manufactures.”Footnote 54 Jefferson explained that Pierre Du Pont had been a “faithful & useful friend to this country,” aiding Franco–American diplomacy from the commercial negotiations of the 1780s to the recent Louisiana Purchase. Despite Jefferson’s pressing, the firm was outbid later in the year by a rival chemist to refine saltpeter at the Schuylkill Arsenal.Footnote 55 After losing the contract, E. I. explained this was not because their competitor could do the work at a cheaper price but that the Philadelphia chemist had likely miscalculated the amount that he could actually return. A few months later, Pierre wrote Jefferson from France, reminding him that his son’s mill deserved support.Footnote 56 His prodding finally produced results. The president concluded that it was “for the public interest to apply to your establishment for whatever can be had from that for the use either of the naval or military department,” and pressed Secretary of War Dearborn to contract with the Eleutherian Mills.Footnote 57 Shortly thereafter, E. I. du Pont received a patent for the use of machines in “granulating gunpowder.”Footnote 58 By the end of 1805, the firm had remanufactured seventy-five thousand pounds of gunpowder for the War Department (a process in which saltpeter is extracted from gunpowder and reincorporated with new sulfur and charcoal), and had gained a standing agreement to remanufacture additional powder through the remaining years of Jefferson’s presidency.Footnote 59

In addition to the family’s connection to the president of the United States, E. I. du Pont also understood the importance of networking within an emergent American military bureaucracy. While the military establishment remained relatively small during the administrations of the Virginia Dynasty, the general staff and purchasing agents that did exist had wide authority to issue contracts in the manner they saw fit. Callender Irvine, the superintendent of Military Stores at the Schuylkill Arsenal, proved to be an important contact for du Pont within the government. While Du Pont de Nemours’ connection with Jefferson was necessary to get the Eleutherian Mills noticed, it was the friendship that developed between Irvine and the Du Ponts that proved a decisive long-term factor for continuing patronage in the form of yearly military contracts, not just for gunpowder but also for woolen goods when the family ventured into other manufacturing enterprises. When Irvine and du Pont began their correspondence in summer 1805, both men were just starting out in their respective fields: the general staff and gunpowder manufacturing. However, by the War of 1812, Irvine had risen to a position in which he was responsible for contracting on behalf of the U.S. Army, a rank that he would hold until 1841. As Irvine’s patronage power grew within the federal government, so too did the fortunes of DuPont.

In 1805 Irvine oversaw the execution of the first federal contract for E. I. du Pont: to remanufacture the powder that the military had condemned as unfit for use.Footnote 60 Over the course of the next five years, the two men corresponded frequently, met often in Philadelphia, and dealt with matters outside of government contracts such as the importation of Merino sheep for Irvine’s farm, and gambling on horse races.Footnote 61 During this time, the War Department continued to direct Irvine to manage the government’s powder contracts with the firm, and the company’s ability to consistently deliver large quantities of quality gunpowder supposedly led Dearborn to announce to a group of army officers on July 4, 1805 that DuPont “shall have all the government work.”Footnote 62 Despite occasional quibbles over price and quality, production continued apace as both Secretaries Dearborn and Eustis continued to issue yearly orders of up to fifty thousand pounds of new powder in the period leading up to the War of 1812.Footnote 63 The government’s steady orders proved fortuitous for the company’s balance sheet. Between 1804 and 1814, federal sales represented between 40 percent and 60 percent of DuPont’s annual production. Preparation for war during peace provided the Eleutherian Mills with a reliable source of income as the firm could count on a consistent demand from the government and that their friends would oversee the execution of contracts.Footnote 64

In addition to these peacetime military contracts, DuPont was aided by a political economy that countenanced the export of munitions. As Table 1 demonstrates, between 1804 and 1811, the production of new gunpowder continued rapidly. Despite a dip in 1808 occasioned by Jefferson’s export embargo, the firm increased both production and revenue year-on-year. Government business was certainly significant, especially the contracts to remanufacture damaged gunpowder. The company was also aided by the Republican Congress’ willingness to let the ban on gunpowder exports expire in 1801 and to reimpose the 15 percent ad valorem tariff. Beginning in that year, as demonstrated by Figure 5, American powder exports rose precipitously, especially as the Haitian Revolution and Napoleonic Wars gripped the Caribbean and Europe. With the resumption of war between Britain and France, E. I. du Pont told his father that “the condition of war that exists in Europe is very promising for my enterprise. I will do all I can to profit by it.”Footnote 65 What would allow the Eleutherian Mills to profit in the first place was Jefferson’s noninterventionist foreign policy and tacit approval of the arms trade. Du Pont went on: “The merchants are delighted that continued neutrality will make it possible for them to profit by the new war. So everyone agrees in approving Jefferson’s policy and even has kind words for France and Bonaparte.”Footnote 66 Profit they did. In June 1805 Spain’s colonial agent in the United States entered into a contract with DuPont for forty thousand pounds of first-quality gunpowder for $13,600, largely because the firm had prior experience producing military-grade munitions.Footnote 67 By October, the full amount of the contract was manufactured and loaded onboard a schooner engaged in trade with Vera Cruz.Footnote 68 Compared to the mercantile competition in New York City, the Du Pont brothers were in a strong position. A month after their contract with Spain, Victor reported to his brother that Samuel Ogden, a prosperous New York merchant, had purchased nearly two hundred thirty thousand pounds of “very poor quality” powder for just $24,000. This powder would likely sell in the Caribbean for $100,000 and “will by no means be sufficient for the demand.”Footnote 69 As long as they were able to produce a superior product, the operators of the Eleutherian Mills reasoned that they could command a significant place in the market.

Table 1 DuPont gunpowder production and revenues, 1804–1833

Source: Data collated from “Work Done at DuPont’s Powder Mills Since the Beginning of their Establishment, 1833,” Longwood Manuscripts, Group 5, Series C, Box 49, Hagley Museum and Library; “Powder Made by E. I. du Pont de Nemours and Company, 1803–1856,” Lammot du Pont Papers, Accession 384, Series B, Folder 48–27, Hagley Museum and Library.

Figure 5 U.S. gunpowder exports, 1791–1820.

Data collected from Lowrie and Clarke, American State Papers: Commerce and Navigation, various pages.

While the Eleutherian Mills clearly benefitted from peacetime contracts, the War of 1812 acted as a test case for its business model. In the immediate lead-up to war, other firms entered the market to compete for government contracts. Some, like DuPont, were built on preexisting sources of capital, while others were able to obtain seed-money granted by the federal government. Gunpowder firms, like other manufacturers, were affected by the dual market forces of embargo and war. The 1807 Chesapeake-Leopard Affair, and the resulting embargo, greatly reduced the ability of American munitions makers to export their wares. However, the elimination of foreign competition through nonimportation, as well as the prospect of securing their own government contracts and supplying the domestic market, induced a number of firms to compete with DuPont. A brief analysis of three firms during the War of 1812 era—DuPont, the Franklin Powder Mill, and the Nitre Hall Powder Mill—demonstrates the mutually reinforcing relationship among capital investment, technology, and peacetime contracting for the development of the munitions industry.

As the War Department’s preferred peacetime firm, the Eleutherian Mills was one of two firms that received the greatest volume, and value, of the army’s wartime powder contracts. Their friend, Callender Irvine, ensured that the company was the first to receive lucrative contracts from his department as they had been a reliable supplier in the past.Footnote 70 Two contracts valued at nearly $400,000 represented approximately half of the firm’s output for 1813 and 1814. Production jumped from a prewar high of 204,000 pounds in 1811, to 519,000 pounds in 1814. Revenues more than doubled in the same interval, while prices increased sixfold. The infusion of cash from the federal government, in both direct and indirect sales, allowed the firm to expand its operations to the Hagley Mills, a little downriver from the original site, purchase large quantities of raw materials, and ramp up overall production. Although the data presented in Table 1 show that less than half of the company’s sales went directly to the government, evidence indicates that federal and state purchasing agents acquired large amounts of DuPont powder on the open market. Before the declaration of war, tests at the Boston Navy Yard indicated that the vast majority of the gunpowder there was unfit for service.Footnote 71 The best solution, according to the local navy agent, was to purchase gunpowder from local merchants at retail prices, as many stocked DuPont powder.Footnote 72 Shortly after the navy expressed a need for their product, the firm forwarded 250 kegs to their commission merchant in that city.Footnote 73 By the end of the year, the Boston navy agent reported that his funds were exhausted “in the purchase of powder to supply the immediate demands of the station,” while the company eagerly expected to sell more at any time.Footnote 74 Despite mills operating in New England that sold a poorer quality product at half the price (profitable Connecticut firms continued to use labor-intensive mortar and pestle through the 1820s), the navy understandably rebuffed these companies in favor of more potent yet higher-priced products.Footnote 75 Between 1812 and 1814, DuPont proved that it was more than capable to supply a large portion of the country’s gunpowder.

While DuPont’s success demonstrates the importance of prior capitalization to meet the military’s needs in wartime, the Franklin Powder Mill shows how firms that relied on the federal government for capital improvements could easily fail, despite technological improvements and robust patronage networks. Immediately prior to the War of 1812, Dr. Thomas Ewell was the chief beneficiary of the navy’s plans to foster domestic gunpowder manufacturing. Unlike the Du Ponts, Ewell did not have an international network of investors with ready capital to invest in machinery, technology, construction, or labor. What he did have was a substantial network within the government and a technical mind. Ewell was a surgeon in the U.S. Navy attached to the Washington Navy Yard, the son-in-law of former Navy Secretary Benjamin Stoddert, and a frequent dinner guest of President Thomas Jefferson. With connections like these, he easily convinced Navy Secretary Paul Hamilton to loan him $10,000 to begin a powder manufactory outside of Bladensburg, Maryland. Shortly thereafter, he obtained a very favorable contract from the navy that had a prewar price per pound double what was offered to DuPont by the army. This contract provided an ample advance, did not require that Ewell post security, and had no limit to the amount of powder that the navy would purchase from the doctor.Footnote 76 It was, in short, a sweetheart deal. Ewell’s government funds were quickly allocated to construction, and in January 1812, the National Intelligencer reported that Ewell’s Franklin Powder Mill was nearly completed and had the capacity to produce two thousand pounds per day.Footnote 77 Soon after construction of the mill, Ewell petitioned President Madison to help him garner further contracts with the federal government because the navy was “pleased to favor my undertaking.”Footnote 78 Federal patronage and contracts allowed Ewell to quickly construct a mill that could rival that of E. I. du Pont in securing federal contracts.

Although Ewell obtained an investment from the government to finance his factory, he ultimately lacked the expertise to construct and manage it. Thus, he sought the help of DuPont and rightfully claimed that the military had provided “assurances of support.”Footnote 79 When E. I. du Pont refused to aid Ewell, the doctor quickly resorted to attacks against his French heritage and connection with Thomas Jefferson.Footnote 80 Du Pont was predictably livid that federal agents created competition for his product. In early June, he cautioned Madison that the navy had placed all private powder mills in danger by doing business with a “shamefull” individual “who has succeeded in drawing upon himself the attention and the favors of the government.”Footnote 81 Two days before the declaration of war on Great Britain, E. I. du Pont published a pamphlet intending to expose Ewell’s untrustworthy nature. His argument was essentially that the federal government should only contract with privately capitalized firms. Those companies directly financed by the federal government would be unable to compete in the market once the country returned to peace. Ewell’s favorable contract distorted the market by allowing the doctor to lure workers away from the Eleutherian Mills by offering higher wages, which were ultimately subsidized by taxpayer money. Du Pont denied the doctor’s claim that the Eleutherian Mills benefited from government contracts and disingenuously argued, “Since the establishment of our factory, we have received but a small share of the government’s patronage.”Footnote 82 If federal agents choose to do business with an unreliable individual with no capital, then the public stood to lose considerable funds and perhaps the war.

Du Pont’s concerns aside, the Franklin Mills benefited from the doctor’s technical mind, even if the firm lacked privately sourced capital and skilled labor. On December 7, 1813, Ewell received three patents for inventions related to “manufacturing gun powder.”Footnote 83 Later that month, he advertised to his competitors that he was willing to lease his inventions for as little as $3,000 per machine and a portion of the firm’s profits.Footnote 84 The technology included the application of steam to purify and incorporate the raw materials, as well as granulate corned powder. His success with these labor saving machines was so great, he reported, that he was able to “discharge half of his workmen from his manufactory.”Footnote 85 Given the real usefulness of these improvements, it might be surprising that Ewell’s gunpowder mill failed by the end of the war. Built by very generous navy contracts, the Franklin Powder Mill was also destroyed when the government withdrew its support.

At the end of December 1812, outgoing Navy Secretary Paul Hamilton awarded Ewell an additional contract that would prove to be the Franklin Powder Mill’s downfall. The contract ostensibly specified that for every one hundred pounds of saltpeter supplied by the navy, the Franklin Mill would return the same weight in gunpowder and receive 1.5 cents per pound to refine the nitre, 6.25 cents to produce the powder, and 20 cents portage for each barrel delivered to the navy yard.Footnote 86 The problem for the government was that they never specified the quantity to be produced by Ewell, and awarded the firm extra expenses. Charles W. Goldsborough, the chief clerk of the navy department (and interim head) read through the contract on January 7, 1813, and immediately wrote to President Madison with his concern that Ewell was defrauding the country.Footnote 87 After receiving approval from Madison, Goldsborough placed a stop on the shipment of saltpeter and sulfur to the Franklin Powder Mill.Footnote 88 A bitter war of words then emerged between Ewell and Goldsborough in the city’s print media. The decisive factor in shaping institutional perceptions of the debate arrived when Goldsborough provided proof that Ewell’s powder was, in fact, far inferior to that produced by other firms for lower prices. Although the commandant of the navy yard initially ordered the acceptance of the substandard powder as it could be used for gunnery practice, incoming Navy Secretary William Jones resolved the matter by refusing to accept any more produced by the Franklin Powder Mill and cancelled their contract. Because Ewell lacked the funds to procure raw materials, and largely relied on the navy for shipments, his business quickly fell behind its competitors. Despite his advanced technology, network, and access to government capital, Ewell was finished as a manufacturer because he failed to meet the government’s requirements on quality.Footnote 89

While the Eleutherian Mills and the Franklin Powder Mill present stark contrasts on the relative importance of capital, technology, networking, and contracting, the Nitre Hall Powder Mill outside Philadelphia offers a middle ground between the two. Two merchants—Israel Whelen and William Rogers—who desired to shift some of their capital into manufacturing started it in 1810 as a venture. Although the firm’s sources of direct funding are unknown, they were certainly aided by European connections. Whelen was the U.S. representative of the Phoenix Fire Insurance Company of London, while Rogers had longstanding ties to British and French mercantile firms (and had even smuggled gunpowder to Saint-Domingue in the 1790s). Because of his position with the Phoenix Company, Whelen was able to parlay his connections to take out a $120,000 insurance policy on the Nitre Hall Powder Mill after deleting the language in the standard printed contract forbidding just such an agreement.Footnote 90 Insurance allowed Nitre Hall to expand without having to stock away cash to cover the unexpected expense of an explosion. By 1812, the firm was in full production and manufactured a product that matched the quality of DuPont.

Nitre Hall’s equivalent product, and its proximity to Philadelphia, garnered them a contract in the same amount as DuPont, as well as notice across the country. One group of Boston merchants explained that in their local market “the prejudice of the purchasers have been strongly in favour of Duponts, but they are generally convinced that yours is as good.”Footnote 91 The company’s success was evident when Callender Irvine wrote to the proprietors on December 10, 1813, informing them to stop shipments to the Schuylkill Arsenal as the government’s storehouse was at its capacity.Footnote 92 The Nitre Hall Powder Mill was a reliable supplier to the War Department throughout the conflict (Table 2 and Table 3). Although the receipt evidence indicates that they did not deliver the full amount of gunpowder for which it was contracted, the Irvine letter indicates that this was simply because the army had more powder than it could actually use.

Table 2 Gunpowder delivered by the Nitre Hall Mill to the Schuylkill Arsenal, 1812–1814

Sources: Receipts of Whelen and Rogers’ Nitre Hall Gunpowder Mill with the U.S. Arsenal in Philadelphia 1812–1814, Israel Whelen Papers, Box 5, Receipts (1809–1812) and Box 6, Receipts (1813–undated), William L. Clements Library.

* Prior to the issue of the first contract, not included in final summations and averages. First contract issued October 10, 1812, for 200,000 lbs. of gunpowder within twelve months (ended October 10, 1812).

** Second contract issued by Callender Irvine, March 1, 1813, with duration of eighteen months (ended September 1, 1814).

*** First contract for 200,000 lbs. completed June 3, 1813, four months ahead of schedule.

Table 3 War Department contracts for gunpowder, 1811–1815

Sources: Accurate data concerning governmental contracts for gunpowder before 1811 is spotty with regards to total gunpowder contracts on the part of government. See the War Department Statement of Contracts…in the year 1811, 1812, 1813, 1814, and 1815.

As the fates of these three firms indicate, peacetime military contracts let by the agents of the War Department continued to play a substantial role in the fortunes of the Du Pont family after the war. The first instance was in a rather unexpected location: the woolen industry. E. I. du Pont had long been a key player in the “Merino Mania” of the early nineteenth century, whereby agriculturalists and manufacturers united to introduce European-bred Merino sheep, and their fine wool, into the American market.Footnote 93 In 1810, E. I., Victor, and Victor’s son, Charles I. du Pont, used profits from the gunpowder mill to construct a water-powered factory to spin woolen yarn and weave fine Merino cloth.Footnote 94 Despite courting patronage for their fine cloth from figures as diverse as the influential Philadelphia legislator and son of the editor of the Aurora General Advertiser, William J. Duane, and rising Republican Congressman William H. Crawford, the woolen company’s principle source of revenue came from military contracts.Footnote 95 Beginning in 1812, Callender Irvine approached the firm to produce woolens because “[i]t is the desire of those who administer the Government to have the army clothed with domestic manufactured articles.”Footnote 96 Despite massive British imports following the resumption of peace in 1815, the firm remained in business because Irvine issued it annual contracts for army broadcloth and regularly advised the Du Pont brothers of the highest possible bid prices that the army could accept for domestically produced cloth.Footnote 97

The government’s relationship with the Du Pont woolen venture, like their relationship with the gunpowder mill, was mutually beneficial. According to Irvine, the army had never had finer uniforms since they had started working with Victor and Charles I. du Pont & Co. After Congress downsized the army in 1821, and reduced the annual appropriation for uniforms, Irvine made sure that the Du Ponts continued to receive textile contracts. In February 1822, Irvine warned E. I. du Pont that the proprietors of factories in Cincinnati, Ohio, and Lexington, Kentucky, were making a concerted push for the government’s clothing contracts. One of these firms, the Cincinnati Manufacturing Company, was well connected as it counted William Henry Harrison among its owners and had previously been “engaged entirely in work for the United States.” Irvine suggested that du Pont “explain this matter to one of your friends in Congress” and emphasize that if contracts were made with persons “having little more than three looms the government must make advances of money, a portion of which must be lost.”Footnote 98 Because the army now totaled 6,000 men, the proper interest of government required that all textiles should be “made in one factory.” Victor du Pont soon sent a letter to Congressman Louis McLane using Irvine’s exact recommendations.Footnote 99 Irvine and du Pont’s intervention in the political realm was apparently successful given that, despite the push of western Congressmen to get federal funds for producers in their states, DuPont remained the principle textile supplier. Victor and Charles du Pont & Co. did a brisk business with the army from the 1810s to the 1830s (Table 4).Footnote 100

Table 4 Value of DuPont woolen contracts with the War Department, 1816–1833

Data for the years 1816–1818 collated from the War Department Statement of Contracts… in the year 1816, 1817, and 1818. Data for the years 1819–1833 collated from the annual contracts made by the War Department found in ProQuest Congressional U.S. Serial Set Digital Collection, H.R. Doc. No. 47, 16th Cong., 1st Sess.; H.R. Doc. No. 80, 16th Cong., 2nd Sess.; H.R. Doc. No. H.R. Doc. No. 41, 17th Cong., 1st Sess.; H.R. Doc. No. 60, 17th Cong., 2nd Sess.; H.R. Doc. No. 59, 18th Cong., 1st Sess.; H.R. Doc. No. 56, 18th Cong., 2nd Sess.; H.R. Doc. No. 101, 19th Cong., 1st Sess.; H.R. Doc. No. 181, 19th Cong., 2nd Sess.; H.R. Doc. No. 221, 20th Cong., 1st Sess.; H.R. Doc. No. 105, 20th Cong., 2nd Sess.; H.R. Doc. No. 86, 21st Cong., 1st Sess.; H.R. Doc. No. 73, 21st Cong., 2nd Sess.; H.R. Doc. No. 89, 22nd Cong., 1st Sess.; H.R. Doc. No. 118, 22nd Cong., 2nd Sess.; H.R. Doc. No. 99, 23rd Cong., 1st Sess.

In the late 1820s, E. I. du Pont gave testimony to the Congressional Committee on Manufactures on the state of their textile firm. While they made some satinet out of Merino wool, and a little linsey for the clothing of enslaved persons, the firm mostly produced rough cloth for the army’s uniforms and blankets. Du Pont was sparing in his specifics on the finances of the firm, and mostly used this opportunity to defend ideological principles underlying tariffs in a liberal and capitalistic society. Despite the preferential treatment shown to the DuPont woolen factory by agents of the federal government, the business was a “losing one.”Footnote 101 The only reason why the firm continued to produce was because they were “carrying on other business, which enabled us to sustain our losses.”

The “other business” that E. I. du Pont referred to was, of course, his Mills of Liberty. Following the war there was a serious question as to whether or not DuPont would continue to hold a large share of the market as numerous other firms, such as the Nitre Hall Powder Mill, offered a product at a similar price and quality. Fortunately for DuPont, the War Department valued its long-standing relationship with the firm. In order to ensure that the company remained profitable despite limited government contracts for the foreseeable future, George Bomford, the acting head of the Ordnance Department, decided to loan federally owned gunpowder back to the firm. In return, DuPont would supply the same amount at a future date. Because the government had gunpowder in its arsenals “far exceeding any probable demand for a considerable period of time,” it was a mutually advantageous loan for both parties.Footnote 102 It is doubtful that Bomford’s plan would have existed had it not been for E. I. du Pont’s direct intervention. In June 1816 he voiced his concerns on the state of the market directly to the Ordnance Department and complained that the competition “paid more mention to [gunpowder manufacturing] as an object of speculation than with any view of improving the art.”Footnote 103 Du Pont was right to be worried as other firms, which boasted French-trained powder manufacturers, had recently applied for contracts to get their own businesses off the ground.Footnote 104 Realizing that his company could lose market share if the competition offered a lower price, E. I. du Pont offered Bomford a deal: if the federal government would loan him poor quality or damaged gunpowder, he could sell that powder on the open market and produce a high-quality product for the government at a future date. Du Pont warned that only the continued patronage of the federal government during the postwar “general stagnation of business” would allow him to produce munitions for future conflicts. Swayed by du Pont’s reasoning, Bomford authorized loans of gunpowder to the Eleutherian Mills in order to ensure the long-term survival of the company. Agents of the Ordnance Department reasoned:

It is considered advisable (by the War & this Department) to spare the Powder belonging to the U. States, on Loan, which may not be of the very first quality, or which might be liable to deteriorate from long keeping in the stores or magazines in which it may be deposited; and to receive in Return Powder of the best quality & proof, as a kind of Interest for the accommodation afforded to the borrower. The Interest of our Manufactoires can also be promoted by such accommodation; enabling the proprietors to anticipate, & increase their sales.Footnote 105

Over the course of the next year, the army loaned more than two hundred thirty thousand pounds of gunpowder to DuPont, which made up roughly one-third of the firm’s total sales for 1817.Footnote 106

The loan of gunpowder greatly strengthened the firm’s finances in the postwar era. Following the termination of hostilities, the Caribbean market’s demand for arms and munitions provided the company with an outlet for wartime surplus. Between 1815 and 1819, U.S. gunpowder exports surged from a wartime low of less than ten thousand pounds in 1814 to greater than nine hundred thousand pounds in 1817. Despite this strong international demand, prices plummeted from the wartime high of 65 cents per pound to 25 cents.Footnote 107 DuPont, however, made up for potential lost revenues through the sheer volume afforded by the government’s loan of substandard powder. In the month of August 1816 alone, the company sold one hundred twenty thousand pounds of gunpowder “for export to Spanish America” through merchants in Baltimore.Footnote 108

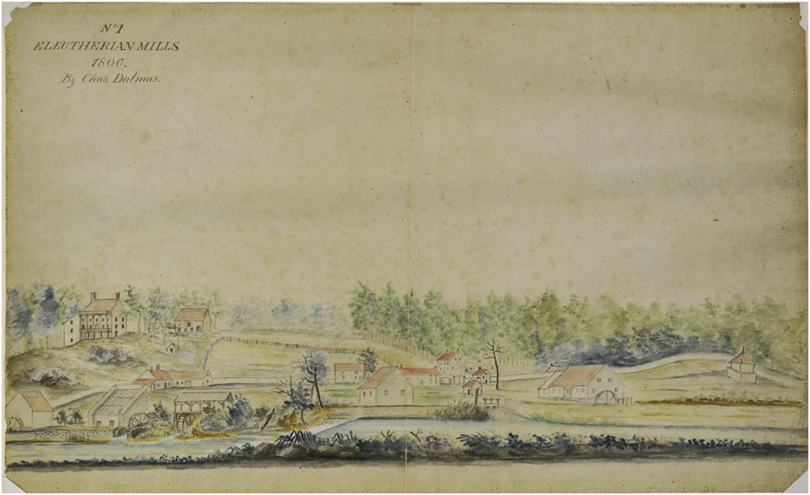

The government’s commitment to DuPont, and vice versa, proved important for the long-term geo-strategic interest of the United States. Supporting domestic gunpowder manufacturers in periods of peace ensured that they would be able to produce munitions during periods of war. When the Eleutherian Mills suffered a catastrophic explosion in 1818, E. I. du Pont reinvested his personal wealth back into the company because he had bright prospects for consistent business (Figure 6).Footnote 109 Within a year of the blast, peacetime production of the firm exceeded even that of wartime. Such an event in American business history was unthinkable two decades prior. By the 1820s, du Pont made frequent reference in his applications for government contracts to the fact that he had kept his company producing powder despite the literal destruction of his skilled labor pool and capital improvements.Footnote 110 The Ordnance Department agreed, and although E. I. du Pont de Nemours & Co. was never able to monopolize government contracts in the antebellum period and Civil War era the way they had during the early decades of the nineteenth century, the firm persisted as one of the country’s principal gunpowder suppliers.Footnote 111

Figure 6 The Mills of Liberty, 1806.

Painting, No. 1 Eleutherian Mills 1806, by Charles Dalmas, Hagley Museum collections, G54.1.P17-6. Courtesy of the Hagley Museum and Library.

That E. I. du Pont de Nemours & Co. was the undisputed leader of the gunpowder industry can be seen in the Manufacturing Census of 1820. That year, DuPont introduced a specially formulated blasting powder designed to aid in the fracturing of rock, which would soon turn it from a company that was largely interested in government business to that of the civilian market. The firm reported to the census taker a total capital of $240,000 invested in six water-powered mills and assorted outbuildings. The previous years’ raw materials cost $55,670, and ninety-five men were paid $36,000 in wages.Footnote 112 These figures, taken alongside the firm’s revenues for 1819 during the midst of a financial panic and collapse in commodity prices, gave the company a greater than 7 percent return on its capital investment for that year.

In comparison, the other gunpowder mills that DuPont had competed with during the War of 1812 did not fare as well. The Nitre Hall Powder Mill, which had supplied at least as much as DuPont during the war, now employed only twenty men between two mills.Footnote 113 Although the firm produced a similar quality product that was priced the same as its competitor, and received wide distribution in the American market, its output according to the 1820 Manufacturing Census was only two hundred thousand pounds per year. This was less than half of what DuPont produced. Despite explosions at the Nitre Hall Powder Mill in 1826 and 1831, it was able to remain in business until its proprietor died in 1841 and the property sold the following year.Footnote 114 Thomas Ewell’s Franklin Powder Mill, on the other hand, was not recorded in the census because it no longer existed. In 1815 the doctor took a position as the professor of chemistry at Dickinson College and retired from the industry, defeated when the fostering hand of the state pulled back.Footnote 115 His mill was subsequently auctioned off in 1817 after Congress refused a petition to pay him for the powder that he had failed to deliver.Footnote 116

The divergent outcomes of DuPont, Nitre Hall, and the Franklin Mill demonstrate the importance of both foreign capital and sustained peacetime government support for the gunpowder industry in the early republic and suggest the importance of military contracting for the nature of state–firm relations in the early republic. As a firm initially organized on the French société en commandite simple, DuPont was able to raise significant foreign capital and parlay that into advanced technology and sustained military contracts. By 1820, it was the largest gunpowder firm in the United States, with a market that penetrated into every state and the wider Atlantic world. DuPont’s early focus on government sales would shape its long future with the federal government, a relationship that would last well through the Cold War. The firm produced munitions for the Civil War, Spanish–American War, both World Wars, and even managed the government’s Savannah River nuclear facility until the late 1980s. In comparison, the Nitre Hall Powder Mill also benefited from access to foreign capital through the connections of proprietor Israel Whelen. His company also produced a product that was similar to that of DuPont, and was able to garner equal contracts during wartime. However, he ultimately lacked the connections to the country’s military bureaucracy necessary to continue supplying the War Department. Despite Nitre Hall’s ability to produce gunpowder on time and on budget, the company received no contracts after the War of 1812. Thomas Ewell, the proprietor of the Franklin Mill, was connected to the navy through professional and familial connections, and was able to obtain three patents from the federal government for his industrial improvements. However, the mill was completely dependent on the federal government for its capital. When federal funding was withdrawn, the company collapsed. As the case of DuPont demonstrates, foreign capital, with its ability to readily procure advanced technology—coupled with the ability to garner peacetime military contracts—were essential features for the success of firms engaging with the federal government to produce munitions during the early republic.