Introduction

The tenth to ninth millennia cal BC in the Near East were a time of great social change, when an Epipalaeolithic hunter-gatherer way of life began to turn into one based on a Neolithic farming economy. While there is hardly any archaeobotanical evidence of morphologically domestic plants, the cultivation of cereals prior to domestication is thought to have been practised at several sites in the Middle Euphrates Valley (Tanno & Maeda Reference Tanno, Maeda, Tsuneki, Yamada and Hisada2016). At the same time, discoveries of Pre-Pottery Neolithic A sites in and around the Euphrates Valley, such as Göbekli Tepe, Jerf el-Ahmar, ‘Abr 3 and Qaramel, have shown a rapid development in symbolic expression. This has often been interpreted as the culmination of hunter-gatherer societies, from which Neolithic farming societies developed (Watkins Reference Watkins2010). The development of a similar material culture, particularly in architecture and symbolic objects, is also seen in northern Iraq and the Upper Tigris Valley (e.g. Nemrik 9, Qermez Dere, Hallan Çemi, Demirköy Höyük, Körtik Tepe and Gusir Höyük) (Kozlowski Reference Kozlowski1990; Watkins Reference Watkins1995; Karul Reference Karul, Höyuk, Özdoğan, Başgelen and Kuniholm2011; Özkaya & Coşkun Reference Özkaya and Coşkun2011; Rosenberg Reference Rosenberg, Özdoğan, Başgelen and Kuniholm2011). Accordingly, the area including the Middle and Upper Euphrates, northern Iraq and the Upper Tigris is often reputed to be the place where a Neolithisation process first began, and has consequently been called the ‘Golden Triangle’ (Kozlowski & Aurenche Reference Kozlowski and Aurenche2005).

On the other hand, recent investigations at Hasankeyf Höyük in the Upper Tigris Valley (Figure 1) have demonstrated that a hunter-gatherer economy continued throughout this period, although the site shares a wide range of its material culture with the contemporaneous sites mentioned above. This view is supported by its lithic assemblage, which is characterised by microliths, with ‘Nemrik’ points (lozenge-shaped projectile points commonly known from Neolithic sites) only introduced in the latest phase of occupation. At first glance, the appearance of Nemrik points seems to mark the transition from an Epipalaeolithic to Neolithic way of life, as they are often considered to be indicative of a Neolithic industry termed, in this region, the Nemrikian, which forms the eastern part of the Golden Triangle (Kozlowski & Aurenche Reference Kozlowski and Aurenche2005). Detailed study of the lithic artefacts of Hasankeyf Höyük demonstrates, however, a continuous tradition of hunter-gatherer lithic technology, suggesting that the use of Nemrik points was not necessarily related to the emergence of Neolithic culture. This study explores how the chipped stone assemblage from Hasankeyf Höyük, characterised by a continuous lack of clear functional categorisation, supports the notion of a hunter-gatherer tradition that persisted into the Neolithic.

Figure 1. Map showing the location of Hasankeyf Höyük and other sites mentioned in the text.

Hasankeyf Höyük: a sedentary settlement of hunter-gatherers

Hasankeyf Höyük is a tell located on the north bank of the upper Tigris in south-eastern Turkey. Since 2011, four seasons of excavation have been carried out by the University of Tsukuba within the framework of the Hasankeyf Rescue and Conservation Project, directed by Abdüsselam Uluçam (Miyake et al. in press). The Tigris forms a narrow valley in this area where the surrounding environment provides a variety of natural resources. Pistachio, almond and hackberry were the most commonly exploited plant resources; wild sheep, goats, red deer and boar were frequently hunted, and fish were also caught. There are no signs of domesticated animals or plants, and the absence of wheat and barley in the plant remains negates the possibility of pre-domestication cereal cultivation.

The archaeological mound is about 150m in diameter and its top is about 8m higher than the surrounding land. Throughout the occupational sequence, more than 30 round, stone-walled, subterranean buildings were found, which were repeatedly re-constructed and used for habitation. Two rectangular subterranean buildings were also recovered in the highest level of the mound. One of them, structure 3, is much larger than the other buildings, and was apparently re-built at least three times, as indicated by three distinct levels of plastered floors. The remains of a stone pillar and other stone structures were found within the building, as well as many human burials beneath its floor. The character of this building is distinctive and suggests that it was used for communal purposes.

The occupational sequence can be divided into two phases based on the architectural remains: the later phase, which is only represented by these two rectangular buildings, and an earlier phase that includes all the other horizons with circular buildings (Miyake et al. in press). The chronological change in the lithic assemblage is observed in a slightly different way between the lowest and middle floor levels of structure 3, with the lowest floor level included in the earlier phase, and the middle floor level in the later one.

The scale of the construction of these solid, well-made buildings suggests that the settlement was fully sedentary in character. In addition, evidence of highly elaborate craft production and the many human burials suggest that Hasankeyf Höyük was a settlement occupied by complex hunter-gatherers.

The lithic assemblage of Hasankeyf Höyük

Over 100000 chipped stone artefacts have been recovered so far. In general, the basic character of the lithic assemblage throughout the archaeological sequence is in line with the local tradition of the upper Tigris. A detailed analysis of 18379 artefacts was undertaken. These were recovered from four round subterranean buildings, structures 1, 8, 30 and 72, and from the upper two floor levels of the rectangular building structure 3 (Figure 2). The order of their construction can be determined because they intercut one another. Structure 72 is the earliest, followed by structures 8, 30 and 1, with structure 3 the latest. Twenty-five radiocarbon dates from these buildings mostly fall between 9600–9100 cal BC (Table S1 in the online supplementary material (OSM)).

Figure 2. Plans of buildings in grid G12 and G13, showing the construction order of structures 1, 3, 8, 30 and 72.

All the statistics presented below are derived from the assemblages from these buildings, although some artefacts found in other contexts are included in the technological and typological analyses (for the additional description of artefact typology, see the OSM). Artefacts were both collected by hand during excavation and recovered through dry-sieving (4mm squares) of the fill deposits from structures 1 and 30, as well as part of those from structures 3 and 8. The range of tool types and the relative frequency of each type in the sieved and un-sieved collections are not remarkably different (Tables S2–3). Most artefacts were recovered from the fill of the buildings, which were backfilled after their abandonment, and are assumed to indicate the overall character of the lithic assemblage at the site rather than documenting the specific context of their use.

Exploitation of raw materials

Flint, which is easily available nearby, accounts for 94.7 per cent of all the chipped stone by quantity, the remainder being comprised of obsidian. The fluvial terrace of the Tigris contains an abundance of flint river-cobbles, often exceeding 0.3m in length. The colour ranges from grey to brown, often with a greyish-purple hue. Seams of flint nodules are also available in the limestone bedrock on the southern slope of the Raman Dağ, about 2km north of the site. This is of a brownish-grey colour and contains blue-grey fossil inclusions. The flaking quality of both types of flint is sufficiently good to knap blades of a regular shape and size. It should be noted that the flint assemblage from the latest phase includes artefacts with traces of intentional heat treatment. They have a pinkish or reddish hue, and a distinctive greasy lustre on the flaked surface (Maeda in press).

Although obsidian is exotic to this region and was present in much smaller quantities, it was used in essentially the same way as flint. Almost all the obsidian has the greenish tinge of peralkaline obsidian, which must have been procured from the sources at Bingöl or Nemrut Dağ. A few obsidian artefacts of opaque black and those with a translucent dark brown tinge, probably from Bingöl calc-alkaline sources, are also present. The dominant use of Bingöl and Nemrut Dağ obsidian has also been geochemically identified at the neighbouring site of Körtik Tepe (Carter et al. Reference Carter, Grant, Kartal, Coşkun and Özkaya2013).

Cores and debitage

Flakes and blades (blades and bladelets are not distinguished in this study) were detached by direct percussion from different types of cores. The conical blade cores show the most regular pattern of blade detachment (Figure 3: 1, 3–5). They are not, however, as regular as those usually seen on bullet-shaped cores used for blade production by pressure-flaking at Nemrik 9, M'lefaat and Karim Shahir in northern Iraq and the Zagros foothills (Hildebrand Reference Hildebrand, Kozlowski and Gebel1996; Binder Reference Binder, Astruc, Binder and Briois2007).

Figure 3. Flint artefacts: 1 and 3–5) conical cores; 2) overshot blade; 6) single-platform core; 7–12) blades; 13) crested blade.

Single-platform cores, which are less standardised than the conical blade cores, are more common (Figure 3: 6). The scar patterns on the discarded cores are not very regular and retain many hinge terminations. Sometimes both blades and flakes were produced from the same cores. Other types include multi-platform flake cores and discoidal flake cores, from which irregular flakes were detached in random order.

Obsidian cores are rare and very heavily exploited, usually with flake scars on all surfaces. The presence of many obsidian blades and some overshot blades, which have typological features identical with flint equivalents, suggests that obsidian blade production was also carried out by direct percussion.

The rarity of crested blades and fine lateral blades, both in flint and obsidian, suggests that core preforming was limited. Neither flint nor obsidian blades are large (approximately half are less than 12mm wide), nor are they particularly regular in shape (Figure 3: 7–12).

Formal tools

Most formal tools were manufactured on blade blanks. Blades and flakes with non-continuous irregular retouch or use-wear are not numerous, and have not been included in formal tools in Table 1. Most tool types were made in both flint and obsidian. Both direct and inverse retouch were frequently used, but no invasive retouch typical of pressure flaking was practised. Tool typologies are not always clear-cut and there are many tools that can be placed between types.

Table 1. Type-list of flint and obsidian (obs.) artefacts from Hasankeyf Höyük. The figures include the artefacts recovered from dry-sieving (for the breakdown of sieved and un-sieved contexts, see Tables S2 and S3).

The most characteristic tools are microliths (approximately 42 per cent of all formal tools discussed here), which were probably used as projectiles by being inserted into an arrow or spear shaft (cf. Olszewski Reference Olszewski, Peterkin, Bricker and Mellars1993; Yaroshevich et al. Reference Yaroshevich, Kaufman, Nuzhnyy, Bar-Yosef and Weinstein-Evron2010). Scalene triangles and foliate microliths dominate the assemblages. Two irregular lunates were also found. There is no evidence for the use of the microburin technique in microlith production.

Scalene triangles have an asymmetrical shape with a steeply angled back (Figure 4: 1–18, Figure 5: 1–3). They are more common in the earlier phases and virtually absent from the later phase. The frequent use of scalene triangles is known from the Trialetian hunter-gatherer industry in Caucasus (Kozlowski Reference Kozlowski1999), the Zarzian Epipalaeolithic industry in the Zagros Mountains (Olszewski Reference Olszewski2012) and also at Hallan Çemi, Demirköy and Körtik on the Upper Tigris (Rosenberg Reference Rosenberg, Gebel and Kozlowski1994; Peasnall & Rosenberg Reference Peasnall, Rosenberg, Caneva, Lemorini, Zampetti and Biagi2001; Kartal Reference Kartal2012).

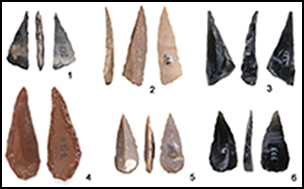

Figure 4. Flint and obsidian artefacts: 1–18) scalene triangles; 19–31) foliate microliths; 32–39) Nemrik points; 40–41) other points. Black dots indicate obsidian pieces.

Figure 5. Microliths and Nemrik points: 1–3) scalene triangles; 4–6) foliate microliths; 7–8) Nemrik points; 3 and 6 are made of obsidian.

Foliate microliths have a symmetrical shape formed by direct, inverse or alternate retouch on one or two sides (Figure 4: 19–31, Figure 5: 4–6). They are sometimes called ‘perforators’ (Kozlowski & Szymczak Reference Kozlowski, Szymczak and Kozlowski1990; Altınbilek-Algül Reference Altınbilek-Algül, Borrell, Ibáñez and Molist2013), ‘foliate Nemrik points’ (Peasnall & Rosenberg Reference Peasnall, Rosenberg, Caneva, Lemorini, Zampetti and Biagi2001) or simply ‘foliate points’ (Rosenberg Reference Rosenberg, Gebel and Kozlowski1994) by other scholars. They are, however, placed in a separate tool category from other microliths because no use-wear indicative of perforating actions has been observed on their tips, and because they are usually smaller than (non-foliate) Nemrik points. The bases of the foliate microliths are round or straight, usually formed by retouch, or sometimes simply formed by the unmodified proximal end of the blade blank. The foliate microliths were shaped in three different ways (see the discussion below).

Nemrik points are another characteristic tool type, frequently found also at Demirköy, Gusir Höyük, Nemrik 9 and Qermez Dere (Kozlowski & Szymczak Reference Kozlowski, Szymczak and Kozlowski1990; Betts Reference Betts, Gebel and Kozlowski1994; Altınbilek-Algül Reference Altınbilek-Algül, Borrell, Ibáñez and Molist2013). At Hasankeyf Höyük they were restricted to the later phase and the surface deposits (Figure 4: 32–39, Figure 5: 7–8). Their lozenge shape is typically formed by inverse retouch at both ends of a blade. Elongated lozenge forms with unretouched parallel sides are more common than the shorter, diamond-shaped version. Another variant has a small tang at one end, demarcated by concave retouch on both sides (Figure 4: 38–39). Elsewhere, they are referred to as ‘Tanged Nemrik points’ or ‘Demirköy points’ (Peasnall & Rosenberg Reference Peasnall, Rosenberg, Caneva, Lemorini, Zampetti and Biagi2001; Kozlowski & Aurenche Reference Kozlowski and Aurenche2005). Blade blanks of heat-treated flint were preferred for their manufacture.

Other types of point, also only present on the surface and in the most recent levels, are distinguished from the Nemrik points by the minimal modification with which their distal tips are shaped (Figure 4: 40, 41). Neither el-Khiam type projectile points nor Gilgal truncations (short truncated blades with bilateral notches, also termed ‘Qermez Dere’ truncations in Watkins Reference Watkins1995), which are common in the Levant and occasionally seen in northern Iraq, were recovered.

End-scrapers are also common in the later phase (Figure 6: 1–6). They are made on thick regular blades, which have often been subjected to heat treatment. They can be divided into a long type (>50mm) and a short type (<50mm). Both types have a steep, round working edge, sometimes on both ends of the blade (Figure 6: 2). Round scrapers, including a few thumbnail types, are also present but in smaller quantities (Figure 6: 7–8).

Figure 6. Flint and obsidian artefacts: 1–6) end-scrapers; 7–8) round scrapers; 9–11) narrow borer; 12–14) oblique truncations; 15) foliate microliths-oblique truncations; 16) foliate microliths-narrow borer; 17) denticulate; 18) borer; 19–20: splintered pieces; 21–24) obsidian tools from human burials. Black dots indicate obsidian pieces.

Oblique truncations have an asymmetrical plan with a retouched truncation at one end, and vary in both size and shape (Figure 6: 12–14). Examples with diagonal truncations on one end of a small blade are known from Neolithic sites in the Zagros foothills, such as Bestansur, Jarmo and Chogha Golan (Hole Reference Hole, Braidwood, Braidwood, Howe, Reed and Watson1983; Zeidi & Conard Reference Zeidi, Conard, Borrell, Ibáñez and Molist2013; Matthews et al. in press), where they are called diagonal-ended blades/bladelets. The examples from Hasankeyf Höyük are, however, more robust and less standardised than these.

Narrow borers, usually made on thick blades and with a rod-like shape, have pointed distal tips and retouched lateral edges (Figure 6: 9–11). No distinct use-wear has been identified so that their use as projectile points rather than as borers cannot be ruled out. By comparison, other borers are much less standardised in their size and shape.

Backed blades, which are common in the Zagros foothills (Olszewski Reference Olszewski2012), are rare at Hasankeyf Höyük. Denticulates (Figure 6: 17) and notches are also rare and lack standardisation. The virtual absence of sickle blades is consistent with the archaeobotanical evidence, which shows the belated development of cereal cultivation in this region (Maeda et al. Reference Maeda, Lucas, Silva, Tanno and Fuller2016). Splintered pieces are common and, unlike other tool types, were always made of obsidian (Figure 6: 19–20). They are also common at Hallan Çemi, Demirköy Höyük and Körtik Tepe.

Although not included in the statistical analysis, obsidian blades and flakes recovered from human burials also deserve consideration (Figure 6: 21–24). They are not particularly elaborate in their manufacture, but have distinctive abrupt retouch or notch-like concave retouch on both sides. These types do not occur among obsidian tools from other contexts.

Discussion

Fluid categorisation in the use of lithics

Throughout the assemblage at Hasankeyf Höyük, there is an absence of clear-cut categorisation with regard to raw material selection, blade and flake production and the manufacture and use of tools.

There appears to have been no difference in use between local flint and exotic obsidian, although the former is much more common. The same types of blades and flakes were produced from both materials, and formal tools made of flint and obsidian are almost identical in size and shape. This is in sharp contrast to later lithic assemblages on the Upper Tigris; for instance, at the Pottery Neolithic site of Salat Cami Yanı, where flint was always used for flakes, and obsidian was reserved for blade production; tools made of flint and obsidian were notably different from one another (Maeda Reference Maeda, Healey, Campbell and Maeda2011).

No clear separation can be identified between the production of blades and flakes. While different types of cores have been identified in the assemblage, many cores do not fall into clear-cut categories. More importantly, it is probable that most cores were reduced in the same way, at least initially. Once a platform and face adequate for regular blade knapping had been created during the initial core reduction, it was followed by the detachment of blades in a regular pattern. These cores were eventually reduced to a regular conical shape (Figure 7: 1). On the other hand, when an adequate platform was available, but the working face was not ideal, irregular blades and flakes were detached without re-shaping the working face of the core. The resulting cores became less standardised single-platform cores (Figure 7: 2). Further, when an adequate platform was not acquired, the platform orientation was changed according to the shape of the cores, which eventually became multi-platform flake cores (Figure 7: 3). The reduction sequence after initial flaking was not pre-determined, and the trajectory of core reduction changed as the knapping went on. It is probable that neither blades nor flakes were produced with clearly distinguished concepts in mind.

Figure 7. Schematic drawing of the various core-reduction sequences documented at Hasankeyf Höyük.

Finally, the typology of formal tools is not always clearly demarcated. For instance, some of the more symmetrical oblique truncations appear similar to foliate microliths that have one retouched side and an unretouched base (and have hence been classified as ‘foliate microlith-oblique truncations’ in Table 1). Some Nemrik points with a less pointed base may be a larger variant of the foliate microlith. Similarly, thicker, elongated foliate microliths are not clearly discernible from narrow borers. Consequently, the typological differences between different pieces are often ambiguous and form a continuum.

Continuity between different types can also be observed in the manufacturing techniques. Three methods can be identified for the shaping of foliate microliths. In the first, a symmetrical shape was formed from a short blade with a naturally pointed distal end with retouch along the edge of both sides (Figure 8: 1). In the second, one end of a longer blade was truncated by abrupt retouch from both sides to make a pointed end (Figure 8: 2). The pointed tip tends to be thicker than with the first method. In the third, a distal part of the blade was diagonally truncated by abrupt retouch in order to produce a pointed end. In this case, the longitudinal axis of the tool is offset from that of the blade blank (Figure 8: 3).

Figure 8. Schematic showing the similarity in the manufacturing methods used for foliate microliths and Nemrik points.

It is apparent that the second method corresponds to the way that narrow borers were shaped, while the third is similar to the way in which oblique truncations were formed. It was also by the second method that Nemrik points were shaped. The difference between Nemrik points and foliate microliths is that both ends of Nemrik points were retouched to a pointed tip, while only one end of foliate microliths was pointed (Figure 8: 4). Some Nemrik points were formed by the third method: a blade was diagonally truncated by abrupt retouch at both ends in parallel in order to make a lozenge-shaped mid-section (Figure 8: 5). In this case, the longitudinal axis of the tool is offset from that of the blade blank, as in the case of the foliate microliths shaped in this way. Frequent use of inverse retouch is seen equally in both foliate microliths and Nemrik points.

It seems that at Hasankeyf Höyük, the boundaries between different raw materials, different production techniques and different tool morphologies were not clearly defined. This contrasts with Neolithic industries, in which flint and obsidian were clearly differentiated, and more specialised blade-production techniques were developed, such as bi-directional naviform methods, for producing thick, large blades with pointed ends, and pressure-flaked bullet core techniques, for the regular production of highly standardised blades (Wilke Reference Wilke, Kozlowski and Gebel1996; Abbès Reference Abbès, Jerf el Ahmar, Hassan, Astruc, Binder and Briois2007).

Chronological change and continuity

Another aspect that should be discussed is chronological change and continuity. Here again, the lack of clear chronological breaks is a key feature of this lithic assemblage. Chronological differences in lithic use were observed in the later phase (the upper and middle floor levels of structure 3): scalene triangles are virtually absent, while Nemrik points and other points appear for the first time, and end-scrapers become more common. In addition, this phase yields the only evidence for heat treatment. These differences must be chronological rather than contextual because the lithic assemblage from the lowest floor level of the same building is much more similar to that of the earlier phase, which includes structures 1, 8, 30, 72 and all the other circular buildings.

A similar chronological pattern can be seen at other sites on the Upper Tigris. The lithic assemblages from Hallan Çemi and Körtik Tepe include many scalene triangles and no Nemrik points, while that of Demirköy Höyük, which is believed to be slightly later according to a greater number of blades and increased standardisation (Peasnall & Rosenberg Reference Peasnall, Rosenberg, Caneva, Lemorini, Zampetti and Biagi2001: 382), includes some Nemrik points and shows a relative decrease in scalene triangles (Rosenberg Reference Rosenberg, Gebel and Kozlowski1994; Peasnall & Rosenberg Reference Peasnall, Rosenberg, Caneva, Lemorini, Zampetti and Biagi2001). The assemblage from the later phase of Hasankeyf Höyük is also closely paralleled at Gusir Höyük, where an absence of scalene triangles, frequent use of Nemrik points and end-scrapers, and evidence of heat treatment are all observed (Altınbilek-Algül Reference Altınbilek-Algül, Borrell, Ibáñez and Molist2013).

It has been proposed that this change may represent a cultural break that occurred at the end of the tenth millennium cal BC in this region (Kozlowski Reference Kozlowski1999; Peasnall & Rosenberg Reference Peasnall, Rosenberg, Caneva, Lemorini, Zampetti and Biagi2001). The evidence from Hasankeyf Höyük, however, shows continuity in lithic tradition, which outweighs the chronological change mentioned above. The continuity is seen in many aspects of the assemblage, including the range of core types, the production methods for blades and flakes, and the undifferentiated use of local flint and exotic obsidian, as well as the ambiguous categorisation of tool types and their manufacturing methods as discussed above.

Furthermore, the nature of the shift from scalene triangles to Nemrik points demonstrates a gradual development rather than their sudden replacement. Figure 9 shows the statistical change over time in the quantity of scalene triangles, foliate microliths, Nemrik points and other types of point recovered from the different buildings. The tools were recovered from the fill of these buildings, which showed no marked difference in their structural and depositional character. The proportion of these tools among all the formal tools in each building demonstrates that scalene triangles decrease through time after structure 8 as foliate microliths increase; Nemrik and other points only appear in structure 3. As discussed above, foliate microliths and Nemrik points are closely related in both typological and technological terms, and thus this seriation suggests a continuous shift from microliths to projectile points, rather than the sudden replacement of the former by the latter. Nemrik points are often regarded as a type that was developed during the Neolithic transition in the Golden Triangle (Kozlowski Reference Kozlowski1999). The evidence from Hasankeyf Höyük, where Nemrik points were introduced in the local hunter-gatherer microlith industry, seems to contradict this idea.

Figure 9. Chronological change in the relative frequencies of scalene triangles, foliate microliths, Nemrik points and other points among all the formal tools in each building.

Conclusions

At Hasankeyf Höyuk, a lithic industry typical of hunter-gatherers persisted across the Neolithic transition until the turn of the ninth millennium cal BC, showing clear differences to the transitional lithic assemblages of the Levant. In the context of the Tigris Valley, this means that Nemrik points cannot be used as a reliable marker for the Neolithic throughout this area, as had previously been thought. The assemblage is characterised by various continuities that are apparent throughout the occupational sequence and by a lack of clear-cut lithic categories.

This contrasts with the situation at contemporaneous sites in the Levant, where gradual change towards a Neolithic industry is observed in the latter half of the tenth millennium cal BC. In the Levant, microliths were replaced by el-Khiam points and eventually disappeared. El-Khiam points then began to be replaced by a diverse array of new tanged projectile points (Aurenche & Kozlowski Reference Aurenche, Kozlowski, Healey, Campbell and Maeda2011). For instance, in the Middle Euphrates, at Mureybet, Jerf el-Ahmar, Cheikh Hasan and ‘Abr 3, Mureybet points, Aswad points, Helwan points and Byblos points, all appear in this period (Kozlowski Reference Kozlowski1999). This change was accompanied by the introduction of a new blade-production technology using opposed-platform naviform cores (Abbès Reference Abbès, Jerf el Ahmar, Hassan, Astruc, Binder and Briois2007), which is distinct from the single-platform, core-reduction technology of the preceding period. The Levantine lithic industries of this period are closer to those of the succeeding period, when a farming economy developed, than to those of the preceding period.

In the Upper Tigris Valley, on the other hand, sites retained a hunter-gatherer economy, which is also reflected in their lithic industry. The routine use of lithics in a particular way may reflect the collective identity of the people who produced and used them, and at the same time play a role in reproducing their shared understanding of their own society (e.g. van Gijn Reference van Gijn2010). If we accept that, then the continuous lithic tradition at Hasankeyf Höyük suggests that it was not only people's daily use of lithics but also their identity as hunter-gatherers that remained unchanged throughout its occupational sequence.

Acknowledgements

This work was supported by JSPS KAKENHI grant numbers 15KK0035, 16K13290 and 24101004, and it was carried out while the author was a visiting scholar at the University of Manchester. I am grateful to Elizabeth Healey for reading an earlier draft of this paper, and very much appreciate her suggestions.

Supplementary material

To view supplementary material for this article, please visit https://doi.org/10.15184/aqy.2017.219