INTRODUCTION

The Beaker site at L’anse de la République (Bay of the Republic), Talmont-Saint-Hilaire, Vendée (France), has been known since the 1960s, and two excavations there in the late 1980s produced copper residues linked to metallurgical activities. Very few sites in France have produced such remains, and when they have done, these are usually shapeless, small and very scarce, so are difficult to identify. Moreover, these rare items are almost never associated with metallurgical features, and when compared with metal objects typical of the Beaker culture (tanged daggers, Palmela points, etc), or probably associated with Beakers (flat axes), the discrepancy between the two groups is striking. These objects are among the oldest known metal artefacts on the Atlantic coast of France, and, in the absence of known copper mines in this region, the question of the origin of the ores remains debatable.

The site of ZAC ‘Les Gabrielle’, Bédée (in Ille-et-Vilaine), is located on a low bluff directly exposed to weathering by marine erosion. Acceleration of the rhythm and intensity of winter storms has resulted in significant erosion of the coastline and the consequent destruction of part of the site. Several surveys in situ have nevertheless shown that abundant archaeological remains are still present. Thus, the threat of the sea, the possibility of finding further traces of metallurgy and especially the wish to characterise the site itself (generally defined as a settlement in the literature) motivated a new excavation campaign in 2014.

This paper focuses on the metallurgical aspect of the excavation; the other finds and results have been addressed elsewhere.Footnote 1 The excavation has produced new finds related to copper metallurgy. These have been subject to extensive petrographic and chemical analysis in order to identify them. Radiocarbon dating of organic residue preserved on pottery confirmed the dating of the site to an early phase of the Beaker culture. The results presented below also provide new insights into the technique for smelting copper ore used by the Beaker metalworkers at L’anse de la République.

THE SITE AT L’ANSE DE LA RÉPUBLIQUE

History of research

The site, discovered in 1968 by Roger Joussaume during surveys along the coast, was characterised by two loci separated by about a hundred metres. Numerous artefacts (mainly ceramics or lithics) were found in the topsoil following coastal erosion. The two rescue excavations carried out in 1988 and 1990 yielded copper residues.Footnote 2 The new excavation took place in September 2014 and produced additional evidence of metallurgical activities.

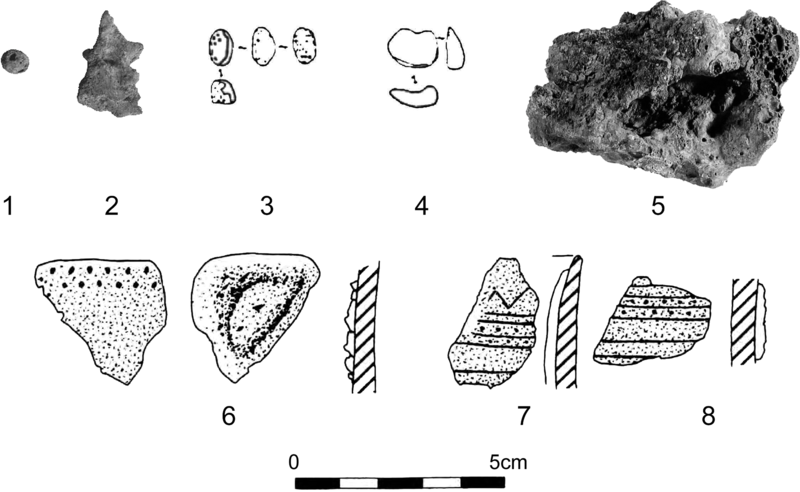

During the 1988 and 1990 operations, abundant lithic and ceramic material was recovered from the occupation level, in hollow structures and in a small hearth (about 2,000 pieces for each type). Ceramics were often fragmented, although some re-assembly was possible; typical Beaker decorations, including incised horizontal lines and triangles made with a comb, were found by the dozen. In addition to these finds, the two excavations produced, respectively, two and four copper slags or nodules related to copper metallurgy (fig 1).Footnote 3

Fig 1. (a) The two slags from the 1988 excavation, no scale. Photograph: after Joussaume Reference Joussaume2009, 141. (b) The four slags found in 1990. No scale but the largest element measured approximately 5cm. Photograph: after Gilbert Reference Gilbert1990.

In 1988, the first copper slag was discovered in a pit and the second in the occupation layer. These two items were analysed in the Rennes laboratory by J-R Bourhis, who describes them thus:

The two samples are fragments of slags mainly composed of a melting medium of silica and iron oxide, the other constituent elements (oxides of aluminium, magnesium, calcium, etc.) not exceeding 1%. The samples are very rich in copper but no metal nodule has been discovered during crushing; the copper is present in its carbonate form because of the clear effervescent reaction with nitric acid.Footnote 4

It seems unlikely that the small pit in which one of the two slags was found was associated with metallurgical activity, as its sides and bottom were lined with blue clay that was still plastic; this excludes any combustion in situ.Footnote 5 Unfortunately, the two residues were lost after the analysis and are no longer available.

In 1990, four new cuprous items were discovered;Footnote 6 the largest of these was found in the centre of a reddish heated area about 30cm in diameter and 20cm deep, interpreted as a hearth. If any soil samples were taken from this structure for analysis, it was not possible to trace the results. Moreover, the four slags from the second excavation were unfortunately lost before being analysed and despite extensive searches in various museum reserves, they remain untraced.Footnote 7

The 2014 finds

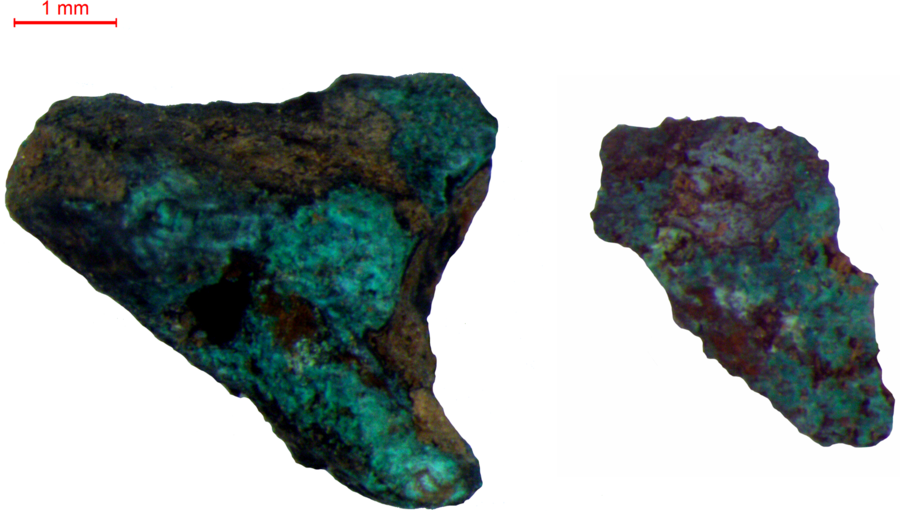

The new excavation at L’anse de la République, carried out in September 2014,Footnote 8 recovered more finds related to metallurgical activities. A cuprous residue less than 1cm long (fig 2) was found in test trench 2 (square J18, US2-II) without any identifiable structure. The vocabulary used by different authors to describe this type of artefact varies widely, thus showing the difficulty in its interpretation. The term ‘residue’ has been preferred in this article, as it was for the site of Fortin-du-Saut, Châteauneuf-les-Martigues, Bouches-du-Rhône.Footnote 9 At Val-de-Reuil and at Le Vivier, Le Clos-Saint-Quentin, Poses, Eure, the authors preferred the term ‘nodule’,Footnote 10 whereas for the site of L’Écuissière at Dolus-d’Oléron, Charente-Maritime, the term ‘slag’ was used.Footnote 11

Fig 2. Copper residue found in 2014 broken in two during the analysis. Photographs: Henri Gandois and Lolita Rousseau.

The coppery aspect of the residue was recognised immediately after its discovery, so all the sediments from this square of the excavation and the adjacent ones were sieved (1mm), but no other copper was found.

Microscopic observation showed on one face large green areas interspersed with smaller areas of orange-brown colour corresponding to the surrounding natural sediment. The other face had noticeably fewer green areas and a lighter background, becoming red (but still with some orange-brown areas). It should be noted that the whole structure seemed rather porous, with small cavities visible on one face, which probably indicated heating to a high temperature. These cavities also made the object very fragile, so it broke in two during handling.

In addition to this residue, one of the sherds from test trench 5 (square H2, US2),Footnote 12 where, as in all the trenches, many ceramic sherds were found, had copper concretions on its inner face (fig 3).

Fig 3. Ceramic sherd with embedded copper prills. (Left) inner face. (Right) outer face. Drawing: Quentin Favrel. Photographs: Benjamin Gehres.

This sherd stands out from the others because of the presence of at least three millimetre-sized greenish residues of coppery appearance: two of these are on the inner surface; the third is embedded in the upper edge of the sherd (see fig 3). Moreover, this ceramic fragment has a grey-blue fabric, which indicates very significant heating that produced vitrification. Observation with a binocular magnifier shows shrinkage of material on the upper edge, which suggests multiple heating episodes since some constituents of the fabric have disappeared. Unfortunately, the absence of form or decoration precludes further study, but the general appearance of the artefact, including its thickness of less than 8mm, is comparable to the coarse domestic pottery which abounds on the site.Footnote 13

The characteristics described here are clearly reminiscent of a domestic smelting vessel, and the description of the sherds recovered at Al-Claus, Varen, Tarn-et-Garonne, could be applied in all respects to the object from L’anse de la République:

[…] about twenty ceramic fragments bear a superficial metallic deposit. These are small sherds whose surface varies between 5cm2 and 30cm2. The ceramics show obvious signs of deterioration from being subjected to intense heat. On their outer surface, the fabric of these sherds has a grey colour, or more rarely orange, and a bulbous texture, with a slagged aspect. The metallic deposits form a thin encrustation deposited on the concave – and probably internal – surfaces of the sherds. They do not cover the whole of the sherds.Footnote 14

In search of new evidence

The vitrified appearance of the sherd with the cuprous residue, which indicated heating to a very high temperature, prompted a review of all the ceramics found previously. Perhaps vitrified sherds without any visible copper residue escaped the attention of the excavators? During a visit to the archaeological store of the Historial de la Vendée museum at Les Lucs-sur-Boulogne, the other ceramic fragments were rapidly reviewed. While, as would be expected, no sherd bore any cuprous concretions – there is no doubt that such traces would have been noticed – some sherds were clearly vitrified, and of these six were selected for analysis. It should be noted that no cuprous residue was visible on the analysed surfaces (fig 4); these sherds looked very much like others from the site. They were discovered more than twenty-five years ago, then washed, handled and packed several times, thereby greatly reducing the probability of any residues remaining.

Fig 4. Inner walls of the vitrified sherds found during the surveys and the 1990 excavation. Photographs: Henri Gandois.

ANALYTICAL METHODS

All the items found either during the 2014 campaign or in the Historial de la Vendée store were analysed by XRF spectrometry to identify their elemental composition using a portable device.

The sherd found in 2014, bearing copper residues on one of its faces, has also been subject to petrographic analysis, metallographic microscope observation and SEM/EDS microprobe analyses.

X-ray fluorescence (XRF) analysis

The analyses were carried out both in the Archéosciences Laboratory (in Rennes) and the Historial de Vendée store, using a Niton XL 3t 900 Gold type analyser. This device bombards the surface of a sample with high-energy X-rays. The sample, thus excited, in turn emits X-rays, the wavelengths of which are related to the nature of the chemical elements present. It is a device that works with pre-established programmes depending on the nature of the materials analysed. The programme ‘Cu/Zn ore’ was chosen as it allows analysis both of the so-called ‘light’ elements, such as silica or alumina, and of heavy elements such as metals. This programme best suits ceramic samples containing metal residues. The detection thresholds are calculated for each analysis and each element; these are given in the results tables.

Petrographic analysis, metallographic microscope observation, SEM and EDS microprobe analysis

Several investigation methods were employed to identify the geological and geographical origins of the raw material used to make this pottery. Firstly, petrographic analysis of the inclusions on a thin-section of the ceramic was done with a polarising microscope. This technique allows characterisation of non-plastic inclusions, and thus identification of the rock lithologies present at the clay source. From this information, it is possible in the most favourable circumstances to suggest a geographical origin for the raw material.Footnote 15 This approach also makes it possible to recognise the treatment of the fabric, such as the addition of a temper and the grinding or sorting of inclusions. It also identifies the structure of the paste, such as its porosity and the organisation of the vesicles.

Secondly, the thin and thick sections (of a polished sherd impregnated with a polymer resin) were observed through a metallographic microscope to detect the presence of possible metal inclusions in the paste, and also their sizes, locations and areas of concentration.

These studies were supplemented by SEM and EDS microprobe analyses. They provided an image of the multi-layer structure of the sherd, and the overall chemical composition of the different areas of the ceramic was observed, as well as the chemical composition of several metallic and mineral inclusions.

RESULTS

XRF: the copper residue

Owing to the very small size and fragility of the object, only XRF analysis was carried out. For conservation reasons (and again because of the fragility of the artefact), the surfaces analysed could be cleaned only with fresh water. It is therefore the visible surface of the object that has been analysed, with all that this implies in terms of corrosion products and potential problems of reverse segregation.Footnote 16 The results presented here (table 1) must therefore be considered from a qualitative rather than a quantitative point of view, even though data are provided in ppm and in percentage.

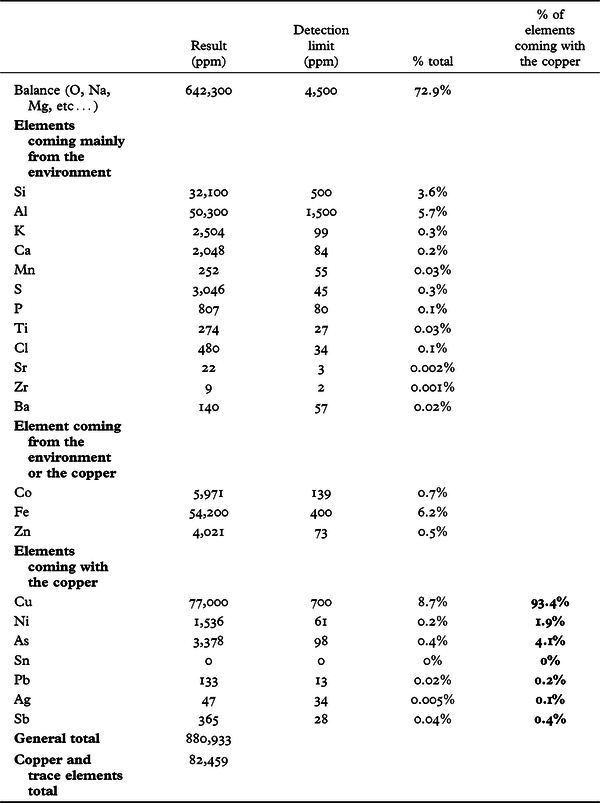

Table 1. Raw and adjusted results of XRF analysis of the copper residue.

The XRF analysis was therefore performed on the face with the most cuprous-like surface, the analysis surface of the apparatus representing 2mm2, so the results (see table 1) inevitably include a significant part of the natural sediment such as iron (a ferromanganic crust is present throughout the site below the Beaker horizonFootnote 17) and possibly even elements from the support on which the object was placed during analysis.

The very high percentage of unmeasured elements (almost 73 per cent), composed mainly of oxygen and sodium, is noticeable. The interpretation of such results always requires great caution. Which are the elements to keep? Which are the elements to discard? What proportion of iron comes from the residue itself or from the natural sediment? The same questions apply for other trace elements.

The question here is whether to list the thirty-six elements that can be identified from the elemental analysis of a metal object, using a list compiled by the Ancient Mining and Metallurgy Committee of the Royal Anthropological Institute.Footnote 18 This list is far too exhaustive to be useful, and, despite modern techniques of analysis, many elements are still not traced. Only the elements that are most commonly found in protohistoric copper/copper alloy analyses are included (that is, Cu, Ni, As, Ag, Sb, Pb and Sn).Footnote 19 Like iron (Fe) for the reasons discussed above, zinc (Zn) has also been discarded, as some of it may come from the environment, despite the fact that some ppm of iron and zinc probably come from the residue itself, so the qualitative nature of these interpretations must be kept in mind.

In conclusion, the copper present in this residue contains mainly arsenic and nickel as trace elements. The presence of arsenic is decisive in confirming that the residue belongs to the Beaker layers of the site. Given the small size of the object, it could perhaps be an intrusive element introduced by root action and/or by the desiccation slots present on the whole site. It should be noted, however, that arsenic is an extremely undesirable component in modern coppers, especially when they are used for electrical conductivity.Footnote 20 The large proportion of arsenic present would therefore indicate that this object belongs to the Beaker levels. Unfortunately, given its size and fragility, it is not possible to go further with the analysis, to state, for example, whether it is a cast residue or a fragment of reduced ore, or even slag from a domestic smelting vessel; it could be either a residue from smelting copper ore or metallic copper melt (see below).

The 2014 sherd with copper prills

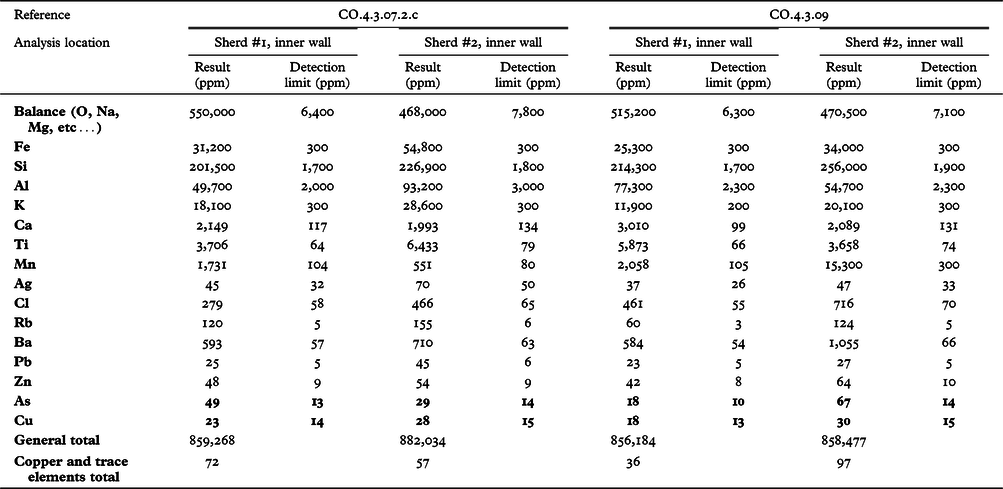

First, it was necessary to ensure that the greenish residues on the inner surface of the sherd did contain copper, even if visually there was little doubt. The sherd was therefore analysed both on its inner and outer surfaces to establish a comparison (table 2). The analysis of the inner surface focused on a greenish area observed during cleaning.

Table 2. Raw results of XRF analysis of the vitrified sherd with copper prills, internal and external faces.

For the reasons stated above, iron (Fe) was omitted from the selection of trace elements occurring with copper, and to facilitate comparison the same trace elements were considered. Once again, unmeasured elements make up the majority (between 55 and 58 per cent), even if the percentages were lower than in the case of the copper residue (almost 73 per cent). For elements derived from the environment, the results of the analyses of the two surfaces were not significantly different and are thus globally comparable. On the other hand, metallic elements were present in very different proportions on the two surfaces: little or nothing appeared on the external surface, with less than 500 ppm in all, against more than 80,000 ppm on the inner part with 86.3 per cent of copper.

In addition to copper, the main elements are Ni (7.53 per cent) and As (4.36 per cent); others do not exceed 1 per cent. These same two elements were also predominant in the results from the cuprous residue, but in reverse order. The total lack of zinc can also be noted, although it was strongly present in the results of the analysis of the residue. This could suggest that the zinc signal came from the support on which the residue was placed during analysis rather than the object itself. Once again, the XRF method of surface analysis does not provide precise results. It is nevertheless significant that the copper inclusions in the sherd contained a high proportion of arsenic and nickel, just like the residue.

The six vitrified sherds from the earlier excavations

These items were studied in situ in the Vendée archaeological store using the same portable XRF analysis tool. The inner surfaces of the sherds were first analysed and when a significant proportion of metallic elements were detected, the outer surfaces were also analysed for comparison.

The first four sherds showed almost no trace of copper, with rates ranging from 18 to 30 ppm for a detection limit of about 15 ppm (table 3). The results for arsenic were similar, the rates barely distinguishable from the margin of error. It can therefore be asserted with confidence that these four objects have not been in contact with copper and so have not been used for metalworking.

Table 3. Results in ppm of XRF analysis of the inner faces of four vitrified sherds found during surveys at L’anse de la République.

The results for the other two sherds (fig 4, right), both from the excavations by J-M Gilbert in Reference Gilbert1990, are more indicative (table 4). The internal faces showed significantly higher copper (and arsenic) levels than the first four analyses. These results prompted analysis of the external surfaces to provide comparative data. The copper levels were between 5 and 10 times higher than on the outer surfaces, while more arsenic was also present, especially on sherd CO.4.3.08.b, on which a second analysis was performed of the inner face.

Table 4. Results in ppm of XRF analysis of the inner and outer surfaces of two vitrified sherds found during the 1990 excavation.

If the levels of copper (Cu = 1,305/1,319 ppm) and arsenic (As = 217/257 ppm) were much lower than those found on the sherd from the 2014 excavation (Cu = 69,300 ppm, As = 3,502 ppm on the inner surface and Cu = 231 ppm, As = 65 ppm on the outer surface), they are nonetheless significantly higher than those found on the other four sherds (Cu oscillating between 18 and 30 ppm). These results clearly indicate that the sherds had been in contact with copper. However, several hypotheses can be proposed for the nature of this contact. Are these additional fragments of domestic smelting vessel? Was the copper detected on the inner surfaces simply from a metallic object buried in the vicinity (such migration onto ceramics having already been observed elsewhere, B Gehres, pers comm, June 2015)? Some observations can help guide our reflections.

Of the six sherds selected and analysed, it is fortunately the one with the highest copper levels that is most clearly recorded: it came from square QQ3 in the 1990 excavation.Footnote 21 However, one of the slags was found in the same square,Footnote 22 which could support the hypothesis that a copper deposit was formed by post-burial contamination. Nevertheless, this hypothesis must be rejected because the small size of the slag in question (barely 10mm) does not suggest the possibility of migration of copper that could impregnate the sherd. On the excavation plan the slag is clearly located in the square, with the sherds and lithic artefacts. As the sherd analysed here was not identified on the plan, no ceramic was in direct contact with the slag. Since all the finds have been identified, this excludes the presence of any other metal object that could have contaminated the sherd. It should also be noted that the eight contiguous squares were also searched manually but no metal objects were found in them, so the other slags must have been found in different squares.Footnote 23

On the other hand, the vitrified appearance of the sherds (very similar to the sherd from the 2014 excavation) and the presence of copper in much larger quantity on the internal face seem to clearly indicate the presence of an additional fragment of a domestic smelting vessel. Only the relatively low copper content compared with that detected on the 2014 sherd (1,319 ppm against 69,300 ppm) may counter this hypothesis. However, this sherd, found more than twenty-five years ago, was washed without any special precautions and handled several times without using gloves. All of this could easily explain the relatively low copper content. It must also be kept in mind that the detection surface for the portable XRF device is only 2mm2, but the metallographic microscope analysis of the copper inclusions present in the 2014 sherd revealed that the dimensions of the latter varied in length from a few microns to several tens of microns (see next section). Furthermore, the SEM image of the vitrified surface of the sherd and the chemical composition of the vitrified surface suggest a certain heterogeneity in the presence of copper. Since no cuprous elements were visible on the surface on the sherd from the 1990 excavation, the portable XRF analysis window was placed on its surface randomly, perhaps within a few millimetres of higher copper concentrations. Finally, the near-absence of copper on the first four sherds analysed supports the hypothesis for the presence of additional fragments of a domestic smelting vessel.

PETROGRAPHIC ANALYSIS, METALLOGRAPHIC MICROSCOPE OBSERVATION, SEM AND EDS MICROPROBE ANALYSIS OF THE SHERD FOUND IN 2014

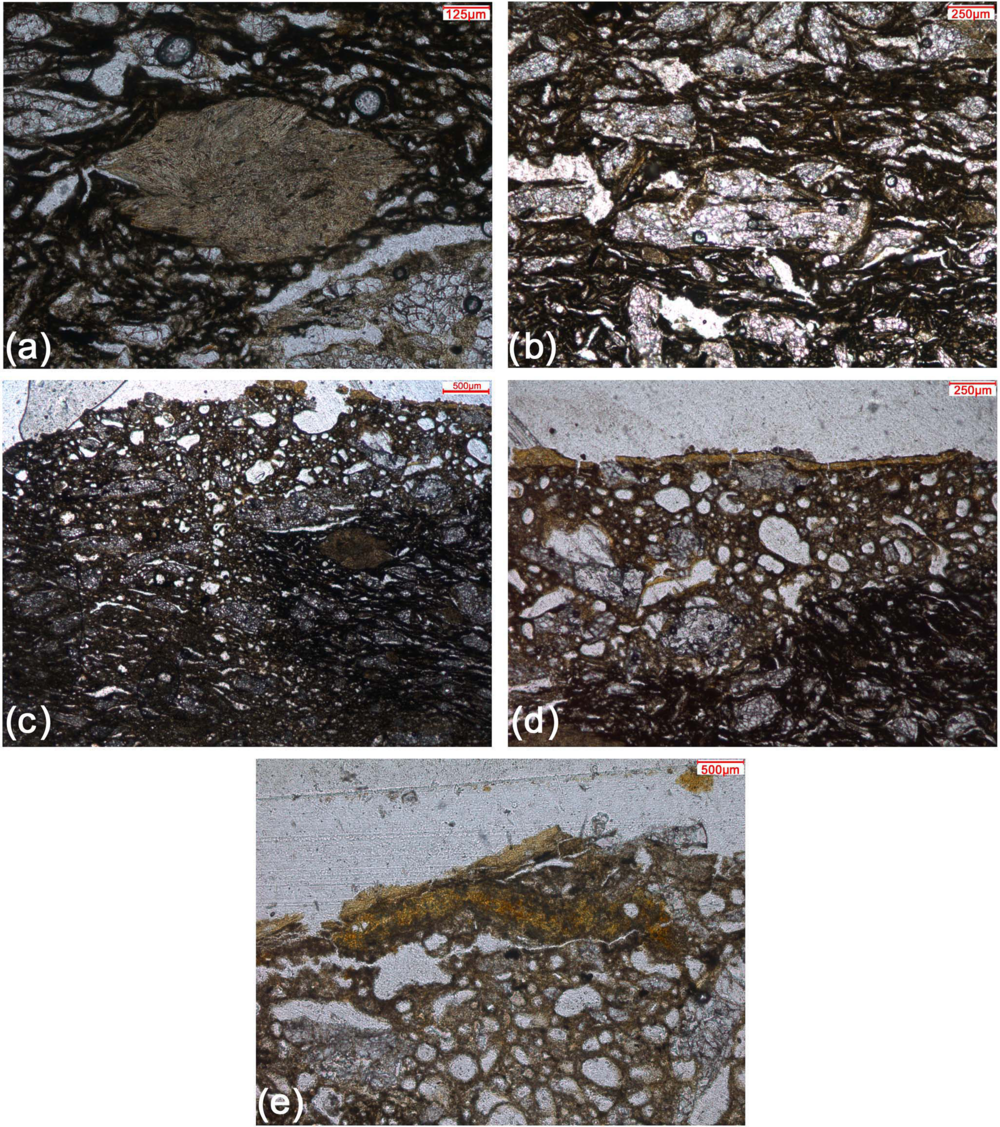

Observations with polarising microscope

Petrographic analysis of inclusions using a polarising microscope revealed a low diversity in the nature of the grains (fig 5). These are mainly quartz, potassium feldspar and chlorite clusters. Many lithoclasts are present in the fabric of this ceramic, composed of quartz grains, potassium feldspar and mica tablets (biotite and muscovite type; fig 5a). These mineral fragments, although very small, have a texture similar to that of a metamorphic shale rock. Most of these inclusions were probably fractured by thermal shock (fig 5b); this phenomenon affected inclusions distributed throughout the fabric. Their shapes are essentially sub-rounded and lenticular. The average size of the inclusions is about 250μm, while the maximum size is 1.3mm, the median being around 160μm. These data, in addition to the authors’ observations, allow the supposition that the potters did not sort the inclusions present in the raw material. In addition, no clay overlay or resurfacing was observed on the walls of the ceramic. The raw material used seems to come from the alteration of a shale metamorphic rock and such rocks do occur near the République site.

Fig 5. Micrographs in unanalysed polarised light (LPNA): (a) clusters of chlorite in the centre of the sherd; (b) fragmented and elongated inclusions dispersed in the sherd; (c) and (d) sherd sections, internal side at the top of the image – notice the arrangement of the different layers: the black border/the vitrified area/the vesiculated area/the core; (e) the vitrified area where the needles were observed. Photographs: Benjamin Gehres.

Observation of the structure of the sherd in thin-section made it possible to identify several layers, impacted more or less differently by temperature (fig 5c and d). A first outer layer, whose thickness varies from about 10 to 80μm, corresponds to clay vitrified under the effect of heat. It is orange in colour and may have a thin black border, a few microns thick, in some areas (fig 5c and d). This area is discontinuous on the outer part of the sherd. It can also include a kind of tongue more orange in colour with hollow and transparent needles a few tens of microns long (fig 5e). Elementary chemical analyses by SEM-EDS determined that these needles correspond to apatite, and the implications of this observation will be returned to below.

Under the vitrified part is a very vesicle-shaped brown area, whose thickness varies between 0.4mm and 2mm (fig 5). Fractured inclusions were observed. The size of the vesicles can range from 20μm to 0.4mm. This area can be observed only on part of the inner surface of the sherd and on the edge of the ceramic. The area becomes thinner further away from the edge of the ceramic.

The central part of the pottery fabric seems to have been less impacted by heating. There are no vesicles, although the grains are fragmented (fig 5). Its colour is darker than that of the vesiculated area, changing from dark brown to black. This area is thicker, ranging from 1 to 4mm.

The last zone is on the inside of the pottery. This is closely similar to the other face, only less vesiculated (fig 5). The vesicles are also smaller and the inclusions are fractured. The thickness of this area is greater than that of the highly vesiculated area and ranges between 40μm and 4mm.

METALLOGRAPHIC MICROSCOPE OBSERVATIONS

Observation of the polished surface of the sherd under a metallographic microscope revealed the presence of orange inclusions, mainly on the inner surface of the sherd (fig 6). Inclusions are mostly concentrated, and the vesicles are largest here. These are sub-rounded and oblong copper inlays, whose size can vary from a few microns to several tens of microns long.

Fig 6. Micrometric inclusions of orange copper – observed with a metallographic microscope. Photographs: Benjamin Gehres.

CHEMICAL ANALYSES BY SEM-EDS

Two approaches were used: a global one, to obtain an average chemical composition of the sherd, and a punctual one, to identify the concentrations of the different elements of several inclusions and to deduce their nature.

The global analyses were made on a polished surface and on a thin-section. The chemical composition of the fabric was recorded by zone, in a transverse manner. The results reveal the use of a clay dominated on average by SiO2, Al2O3 and FeO, and show little variation in these components (it should be noted that the global analysis focused on areas where the amount of inclusions may fluctuate). These are the main constituents of the observed mineral inclusions and therefore confirm the thin-section petrographic observations.

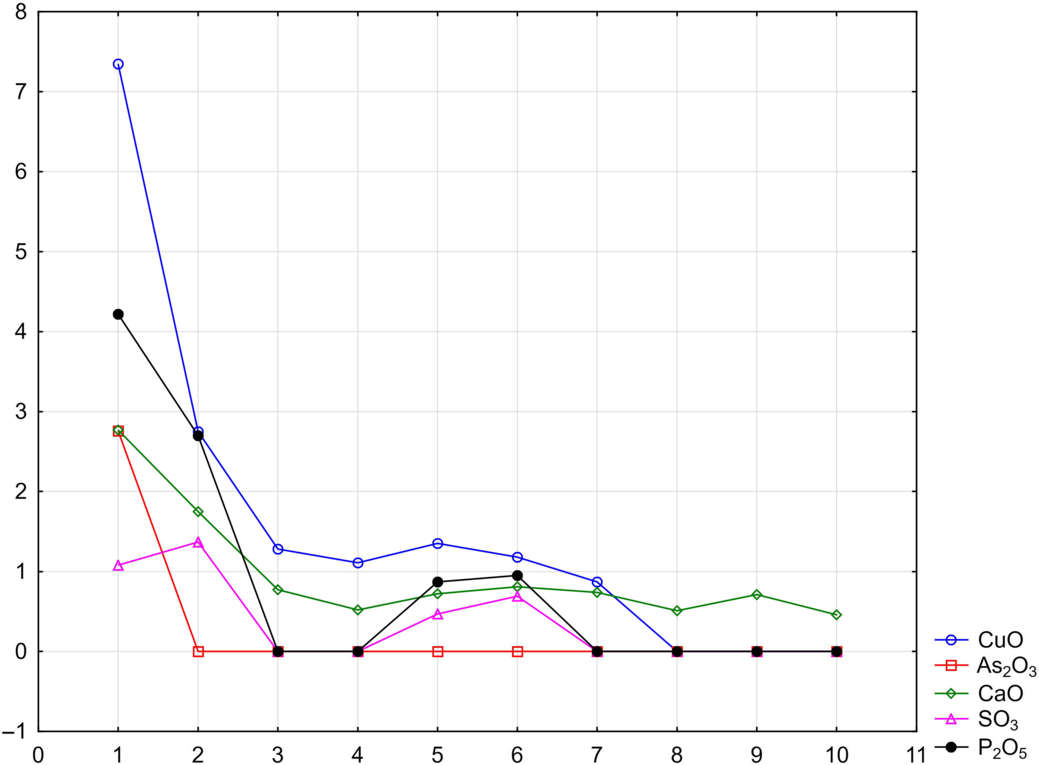

The CuO is present up to 1 per cent on the thin-section and up to 7 per cent in the polished sherd. This difference can be explained by the fact that some of the copper inclusions were probably ejected from the thin-section during its preparation. In addition, there is a decrease in CuO concentration in the sherd further away from the very vesiculated inner surface (fig 7). This reduction is correlated with the concentrations of As2O3, CaO, P2O5 and SO3.

Fig 7. Concentration profiles of CuO, CaO, SO3, As2O3 and P2O5 (in %) on a cross-section of the sherd. There is a significant decrease in concentrations as a function of the distance of the part in contact with the load. Photographs: H. Paitier, INRAP; drawing: Benjamin Gehres.

Several punctual analyses were also carried out to answer specific questions related to thin-section observation. Thus, the analysis of the black border, observed under a microscope and present on the inner surface, corresponds to a copper crust. The CuO concentration in this area can reach 90 per cent. In addition, CuO is bound in some parts of the edging to As2O3, NiO and Sb2O3. Analyses of the vitrified inner part where needles were observed show the presence of CaO, As2O3, P2O5 and some traces of CuO (table 5), which are almost absent in the rest of the sherd. These are calcium and arsenic phosphates and apatite. They are present only in this vitrified tongue and were probably neoformed during the cooling of the pottery after its use as a domestic smelting vessel.

Table 5. Chemical compositions (in %) of the needles observed in the vitrified zone by SEM-EDS. The elements are in the form of oxide and in %.

Finally, the copper inclusions were analysed to obtain a global chemical composition of the metal globules (table 6). Observed was the presence of grains concentrated in Cu, close to 90 per cent, and others with a more heterogeneous composition, in particular with Sb2O3, ZnO or NiO present.

Table 6. Chemical compositions (in %) of the metallic inclusions of the ceramic obtained by SEM-EDS of the polished sherd. The elements are in the form of oxide and in %.

This pottery must, therefore, have been used for an activity related to copper metallurgy. Petrographic and chemical analyses of the fragment showed the use of local clay and the presence of copper globules in the fabric, but also the neoformation of apatite needles that could be related to the addition of ash or bone. The impact of high-temperature heating was highlighted through observation of the fractured quartz grains and the vesiculation of the paste. The evidence collected during this study suggests that fuel and ore was attached to the inner face, as shown by the vesicles and copper inclusions in the ceramic, while the less vesiculated outer face was affected by the temperature of the heating. The absence of resurfacing of the vessel was noted during the observation of the sherd with the SEM.

The presence of SO3, NiO and As2O3 in the surface of the sherd that was in contact with the contents of the vessel indicates that this process was related to the reduction of ores rich in arsenic and nickel (which would not release sulphur). P2O5 concentrations can be explained by the use of a binder added to the ground-up ore to produce a malleable ball based on ash or crushed bone.

All the results summarised here, when compared for instance with the analyses of some ceramic fragments with copper inclusions found in Spain and southern France,Footnote 24 show clearly that this sherd was part of a domestic smelting vessel; that is, a coarse pottery vessel used to smelt copper oreFootnote 25 and known as ‘vase-four’ in French (from the Spanish vasija-horno).

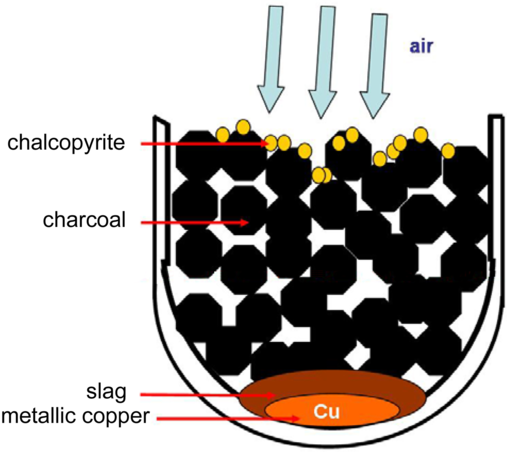

This very simple technique for smelting copper ore to metal was recognised in the late 1980s and confirmed at a Beaker site near Madrid.Footnote 26 It consists in the use of coarse pottery as a reactor for the smelting: finely ground ore was mixed with charcoal and the result placed in the vessel. Using air forced into the inside of the vessel, the mixture would be brought to a very high temperature, thus smelting the ore (fig 8). Thus, if the discovery of slags during the 1988 and 1990 operations left no doubt that metalworking occurred on the site at L’anse de la République, the discovery and rediscovery of sherds of domestic smelting vessel only confirm this metallurgical activity. From a chronological point of view, this metalworking is particularly precocious: an organic residue found on pottery was dated in 2015 at the CEDAD (Centre for Dating and Diagnostics) laboratory of the University of Lecce in Italy. This new date turns out to be precise, unlike the two previous radiocarbon dates (GIF 3828 = > 3850 +/− 130,Footnote 27 GIF 5570 = > 3920 +/− 100Footnote 28): LTL 15214A = > 3966 +/− 45 bp, that is, 2571–2307 cal bc with 2 σ. This result places the site in an early phase of the Beaker culture, and validates the early date suggested by the ceramics.Footnote 29 Although early metallurgical activity has long been suspected on the Atlantic coast of France, this is the earliest date established for this final stage in the ‘chaîne opératoire’ of extractive metallurgy.

Fig 8. Use of a domestic smelting vessel. Drawing: after Burger Reference Burger2008.

THE MEAGRE EVIDENCE FOR BEAKER METALLURGICAL ACTIVITY IN FRANCE

The finds from L’anse de la République may seem very limited, but the traces of Beaker metallurgy in France are extremely rare and more significantly found without any direct link to smelting or casting activity. This study provides an opportunity to review that evidence.

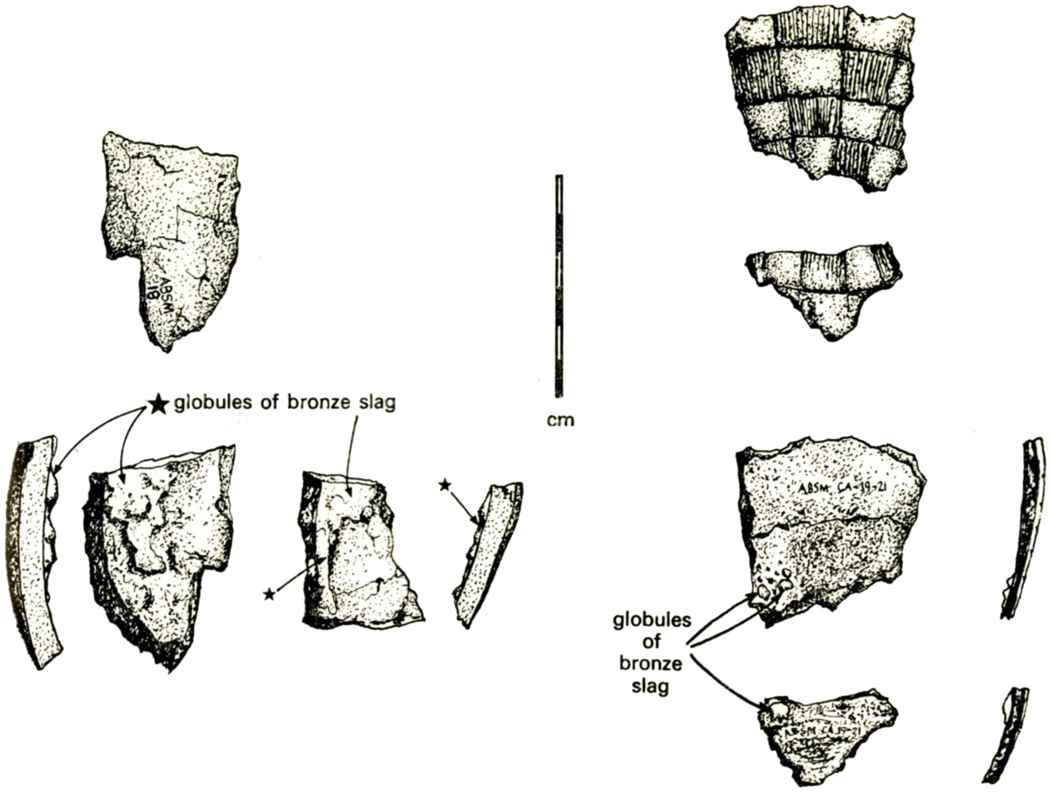

The first known site, even if the finds related to metallurgy are recent discoveries, is Le Fortin-du-Saut, Châteauneuf-les-Martigues, Bouches-du-Rhône, discovered at the beginning of the twentieth century.Footnote 30 However, it was attributed to the Beaker culture only in the 1970s.Footnote 31 In 2002 a ‘ball of copper residue 6mm in diameter, which could be interpreted as a casting droplet, and a copper fragment of half a cubic centimetre that can be interpreted as casting residue’ (fig 9, 1–2) were recovered. These two items do not seem to be related to a particular structure. The discovery of a stone tool with an indentation (‘cupule’) on either face could also be related to metallurgical activity, such as the crushing of ore or slag,Footnote 32 but it is not impossible that it may be an anvil for flint knapping. The site is dated to an early phase of the Beaker culture.Footnote 33

Fig 9. Material associated with Beaker metallurgy. (1–2) Prill and casting residue from Le Fortin-du-Saut, Châteauneuf-les-Martigues, Bouches-du-Rhône (after Furestier et al Reference Furestier, Cauliez, Lazard, Lemercier, Pelissier and Courtin2007); (3–4) ‘nodules’ from Les Florentins, Val-de-Reuil, Eure (after Billard et al Reference Billard, Bourhis, Desfosses, Evin, Huault, Lefèbvre and Paulet-Locard1991); (5) slag from L’Écuissière, Dolus-d’Oléron, Charente-Maritime (after Querré Reference Querré2009); (6–8) sherds of domestic smelting vessel from Le Travers des Fourches, Villeveyrac, Hérault (after Montjardin Reference Montjardin1996).

At Les Florentins, Val-de-Reuil, Eure,Footnote 34 in sector B between a pit and a probable domestic structure, two copper centimetre-sized nodules were recovered (fig 9, 3–4). These two items are interpreted as evidence of either metal production, or transport and trading of raw materials, or both.Footnote 35

Also in the Eure, the site of Vivier, Le Clos Saint-Quentin, at Poses also produced a small nodule about 2cm × 5mm.Footnote 36 The presence beside this copper fragment of small pellets of burnt clay could represent the remains of a metallurgical furnace within a specialised activity area.Footnote 37

The site of Le Travers des Fourches at Villeveyrac, Hérault, produced three typical decorated Beaker sherds with internal concretion (porous slag) containing cuprous traces analysed by J-R Bourhis (fig 9, 6–8). A fragment of ore, probably malachite, was identified, and hence evidence for metallurgical activity.Footnote 38 Bourhis believed the material he analysed was probably a small residue of ore embedded in the porous slag stuck on the inside of the vessel. It contained noticeable traces of silver indicating a local ore.Footnote 39 These sherds could come from a hut.Footnote 40 Because of its pottery, this site is attributable to the Pyrenean Beaker culture (2400–2150 bc).

The largest object was found at L’Écuissière, Dolus-d’Oléron, Charente-Maritime.Footnote 41 This is a copper-ore smelting slag (unpublished research; C Le Carlier, pers comm, March 2014) measuring about 6.5cm × 5cm × 4.5cm and weighing about 200g (fig 9, 5). The site represents Beaker occupation located on the upper part of the current foreshore on L’Ecuissière beach;Footnote 42 unfortunately, the exact location of the slag has not been published. The pottery dates to the middle and later phases of the Beaker culture.Footnote 43

Finally, it should also be noted that a complete ingot mould – in a context whose ‘ceramic corpus evokes, by its stylistic and technical characteristics, the regional Beaker products’ (fig 10) – was discovered at Crec’h-Choupot, Trédarzec, Côtes-d’Armor.Footnote 44 The fragment of another possible mould was found at the ZAC Les Gabrielles, Bédée (Ille-et-Vilaine), also with pottery of the late third millennium, but without characteristic Beaker features.Footnote 45 This pottery has not been examined for possible traces of copper or other elements so its use for metalworking remains uncertain.

Fig 10. Probable ingot mould attributable to the Beaker culture: Crec’h-Choupot, Trézardec, Côtes-d’Armor. Photographs: H. Paitier, INRAP; Drawing: after Nicolas Reference Nicolas2014.

Thus, the direct evidence for metallurgical activity associated with the Beaker culture is extremely rare and particularly tenuous; moreover, the items concerned do not generally have clear remains of combustion, so the chaîne opératoire is difficult to understand.

DISCUSSION

Quantitative and qualitative analyses of the remains discovered in 2014 at L’anse de la République and related to metallurgy show that the copper produced there contained two major impurities: arsenic and nickel. The composition of the copper residue appears to be a very highly arsenical copper (more than 4 per cent) with a high proportion of nickel (more than 1 per cent). However, given the arguments rehearsed above – particularly concerning the proportion of each element that could come from the soil or from the object itself – too detailed an interpretation of these results would not be justified, for example by using the method of multiplying co-efficient developed by Klassen,Footnote 46 to identify comparative data.

The presence of arsenic and nickel in Beaker coppers is very often noted, and the latter element has even been used to discriminate between the different types of copper produced by Beaker metalworkers, notably in the definition by Stuart Needham of two metal groups distinguished by their proportion of nickel:Footnote 47 LNBB (Lower-Nickel Bell Beaker, where Ni ≈ 0.1 per cent) and HNBB (Higher-Nickel Bell Beaker, where Ni ≈ 0.75 per cent).

Many arsenical copper objects with a high proportion of nickel are known in France, and a number of them can be related to the Beaker culture. Among artefacts with more than 3 per cent As and more than 1 per cent Ni, can be mentioned:

the dagger from La Fare, Forcalquier, Alpes-de-Haute-Provence – As = 3 per cent, Ni = 2.75 per cent;Footnote 48

the dagger from La Socour–Le Bosquet, Bettencourt-Saint-Ouen, Somme – As = 3 per cent, Ni = 5.2 per cent;Footnote 49

the dagger found with a Beaker vessel in the Bassin de Penhoët at Saint-Nazaire, Loire-Atlantique – As = 6.18 per cent, Ni = 1.639 per cent;Footnote 50

the dagger from Soulac-sur-Mer, Gironde – As = 3.9 per cent, Ni = 5.4 per cent.Footnote 51

These objects are all daggers, which may not be fortuitous; however, as extremely few flat axes are associated securely with Beakers, the evidence is typologically biased. Nevertheless, among the Beaker objects analysed, those with more than 1 per cent of nickel are in a minority.Footnote 52 It can also be noted that a flat axe found in the same commune as the République site has an arsenic content of 1.5 per cent, but only 0.08 per cent nickel,Footnote 53 indicating an ore of different origin.

A Spanish origin has been proposed for ores with this remarkable presence of both arsenic and nickel within the same metal.Footnote 54 These two elements are present in the malachite from the mine at El Aramo, Asturias,Footnote 55 but also in the copper from the central cordillera of Spain.Footnote 56 In the absence of other analyses (of lead isotopes in particular), it is not possible to explore this Spanish origin any further here, but it is a possibility that must be borne in mind. The lack of any traces of copper mining on the Atlantic coast of France, again contrasting with the number of copper objects found, is still very problematic. But, as noted by Poissonnier, quoting an old text, the presence of copper mines in Vendée is not necessarily impossible: ‘In the middle of the eighteenth century, Charles-Rene Girard de Villars, born in 1698, wrote: “We found a poor copper mine in the villages of Cloux and Chaffeaux”.’.Footnote 57 This has also been suggested by Joussaume: ‘It would not be surprising, however, to discover in the Vendée copper deposits that could have been exploited.’Footnote 58

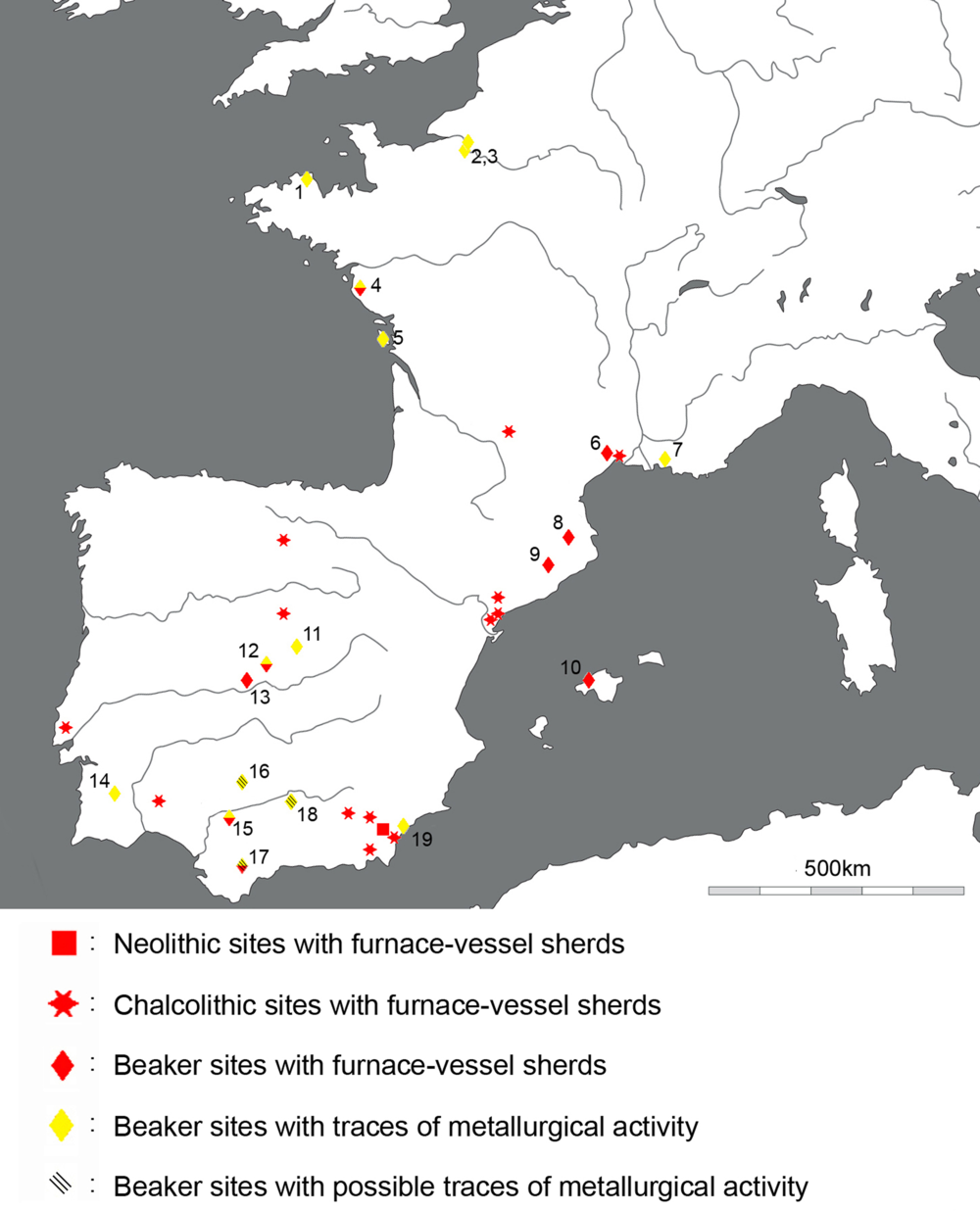

Nevertheless, the hypothesis of a Spanish origin of the ore can be further supported by the method used for smelting: the technology of the domestic smelting vessel. This technique seems to have been particularly well-developed in the Iberian Peninsula from the Neolithic until the Iron Age, with more than thirty known examples.Footnote 59

To the authors’ knowledge, only four sites in France from the second half of the third millennium bc, have produced fragments of domestic smelting vessel: Le Travers des Fourches, Veyrac, Hérault;Footnote 60 Al-Claus, Varen, Tarn-and-Garonne;Footnote 61 a pit at the mine at Pioch-Farrus; and Le Cadenas no. 1, Cabrières, Hérault.Footnote 62 This article does not discuss smelting crucibles, which are specially made and characterised by very thick walls and a small internal volume,Footnote 63 while domestic smelting vessels are, in contrast, coarse pottery vessels re-used for smelting.

The first site (Le Travers des Fourches) is partly dated to the Beaker culture and has produced three decorated sherds with internal concretion described as ‘porous slag’,Footnote 64 out of a total of 126 decorated Beaker sherds, so there is no doubt that the Beaker metalworkers there did use smelting-vessel technology. The excavators noted the lack of Beaker coarse pottery, but as this site had several phases of occupation, this can be explained by the attribution of some undecorated and undiagnostic sherds to the local Ferrières culture.Footnote 65 The other sites are dated to the Late Neolithic; one of the dates from Al-Claus (2448–2175 cal bcFootnote 66) makes it contemporary to the Beaker culture, but without any characteristic finds. Here, sherds encrusted with copper are relatively numerous in absolute terms, but not in proportion to the total ceramic corpus (twenty-six of more than 1,600 sherds).

The introduction to France from the Iberian Peninsula of the technique of smelting copper ore using domestic smelting vessels, known there since the Neolithic, was firmly rejected in 2002 by S Rovira and P Ambert, who suggested local invention.Footnote 67 However, the current distribution of sites where smelting-crucible sherds have been found in western Europe casts doubt on this (fig 11).

Fig 11. Sites with smelting-crucible sherds or elements of Beaker metallurgy (only Beaker sites have been included). (1) Crec’h-Choupot, Trédarzec, Côtes-d’Armor; (2) Les Florentins, Val-de-Reuil, Eure; (3) Vivier, Le Clos Saint-Quentin, Poses, Eure; (4) La République, Talmont-Saint-Hilaire, Vendée; (5) L’Écuissière, Dolus-d’Oléron, Charente-Maritime; (6) Le Travers des Fourches, Villeveyrac, Hérault; (7) Le Fortin-du-Saut, Châteauneuf-les-Martigues, Bouches-du-Rhône; (8) La Bauma del Serrat del Pont, Tortellà, Girona; (9) La Cova del Frare, Sant Llorenç del Munt, Matadepera, Barcelona; (10) Son Matge, Mallorca; (11) Camino de las Yeseras, San Fernando de Henares, Madrid; (12) Villaviciosa de Odón, Madrid; (13) El Fontarrón, Toledo; (14) Três Moinhos, Baleizão, Beja; (15) El Acebuchal, Carmona, Sevilla; (16) La Loba, Fuenteovejuna, Córdoba; (17) Ronda, Málaga; (18) Guta, Castro del Río, Córdoba; (19) Las Pilas, Mojácar, Almería. Map: after Rovira and Ambert Reference Rovira and Ambert2002, completed.

The Beaker sites are quite numerous in Spain; thus, La Bauma del Serrat del Pont, Tortellà, Girona, has produced the most important group of domestic smelting vessels from this culture: sixty-nine sherds representing a minimum number of eighteen vessels, some decorated, have been recovered.Footnote 68 During surveys at El Fontarrón, Toledo, a copper-encrusted sherd with Beaker decoration was found.Footnote 69 Also during a survey, two undecorated sherds with cuprous residues, associated with Beaker material, were found at Villaviciosa de Odón, Madrid.Footnote 70 The site at La Cova del Frare, Sant Llorenç del Munt, Matadepera, Barcelona, has also yielded fragments of pottery used for smelting ore.Footnote 71

Finally, a site at Son Matge on Mallorca in the Balearic Islands seems to have gone unnoticed in the inventory of the early 2000s, although it produced several Beaker sherds, some decorated.Footnote 72 This smelting method had not yet been formally identified in 1979, so the author identified the undecorated sherds as fragments of crucibles, and spoke of ritual use in ceremonies for the decorated ones;Footnote 73 however, the illustrations of the undecorated sherds clearly show coarse pottery (fig 12).

Fig 12. Sherds of Beaker domestic smelting vessel with copper inlay from Son Matge, Mallorca. Drawings: after Waldren Reference Waldren1979, 55, fig 16, and 56, fig 18).

For the metallurgical process discussed here, only finds with a clear and direct association with characteristic elements of the Beaker culture have been included. For example, at La Loba mine, Fuenteovejuna (Córdoba, Spain),Footnote 74 the association of copper slags with Beaker pottery is not certain even if it is possible,Footnote 75 so this site has not been taken into account.

Although the remains discovered at L’anse de la République and the results of their analysis do not prove that both the ore and the technology concerned originated in Spain, there are nevertheless hints that make this hypothesis credible, with diffusion by cabotage along the southern coast of the Bay of Biscay. Lead isotope analysis of the surviving material should confirm or deny this route.

CONCLUSION

Vestiges of Beaker metallurgy (apart from the products themselves) remain in all cases very rare in France and to a lesser extent in Spain. This is also the case for other phases of the Chalcolithic and Bronze Age when there was the same discrepancy between workshops and products. Material remains of smelting and/or casting activity are very scarce and only excavation with systematic sieving can recover metal residues, like the recent work on a Late Bronze Age workshop at Montélimar, Drôme, where the excavation record includes more than 200 casting remains.Footnote 76 On the République site, systematic sieving might have revealed other metal residues, but this is a very time-consuming process and therefore not always possible.

Whatever the methods of excavation adopted, traces of Beaker metallurgy are still extremely tenuous. Nevertheless, use of domestic smelting vessels could at least partly explain the lack of evidence. This method, as this article has shown, requires the ceramic vessel to be heated from the inside, which would leave little trace of burning on the ground surface. At the end of the smelting process, if copper mixed with the slag was embedded in the walls of the vessel, it would probably need to be broken in order to recover the valuable metal globules.Footnote 77 Moreover, the effort required to produce coarse pottery for everyday use (made on the site, or in its immediate vicinity as in the case of la République), would have been limited and its destruction is not unlikely. If Beaker metalworkers did use this ore-smelting method, it would have left almost no archaeological trace, and this seems to be confirmed by the current evidence. In addition, for the production of artefacts, the use of sand moulds (totally destroyed after each casting) has been suggested to explain the extremely small number of moulds compared with finished objects.Footnote 78 The use of these two methods – domestic smelting vessels and sand moulds – would leave almost no archaeological remains either of structures or artefacts, especially if the ceramics were broken in order to recover any copper embedded in them.

Nevertheless, this somewhat pessimistic conclusion is clearly moderated by the rediscovery of smelting-vessel sherds from the 1988 and 1990 excavations in the Vendée archaeological store. These fragments could not be identified with the naked eye, and it was the XRF analysis of their surface that revealed high levels of copper. It is therefore quite possible that there are other remains of domestic smelting vessels from old excavations in other museum stores. Almost twenty years ago, A-C Gros noted that ‘it would be good to check whether the storehouses contain any fragments of crucibles or coarse pottery with copper deposits’.Footnote 79 The flexibility and ease of use of the portable XRF equipment should make it easy to establish if the smelting of ore using domestic smelting vessels was used extensively by Beaker metalworkers, especially in southern of France if we assume that this technique came from Spain. The discovery of cuprous remains, invisible to the naked eye, on sherds from old excavations at L’anse de la République is quite encouraging from this point of view. Despite the cleaning and handling they may have undergone, the presence of copper and arsenic can still be detected, quite different from the sherds that have never been in contact with copper. It is therefore suggested that sherds with a vitrified appearance found during old Beaker excavations should be analysed with the simple and practical tool that is the portable XRF. Additional fragments of Beaker domestic smelting vessels could be discovered, even though nothing is visible to the naked eye, which would certainly shed new light on Beaker metallurgy. If this turns out to be the case, it would prove that Beaker metallurgy was a predominantly domestic activity, carried out on a small scale with simple techniques, but also that knowledge of metallurgy was widespread and extensively shared.

ABBREVIATIONS AND BIBLIOGRAPHY

Abbreviations

- EDS

energy-dispersive X-ray spectroscopy

- GIF

laboratory in Gif-sur-Yvette, Essonne

- LTL

Landnám tephra layer

- ppm

parts per million

- SEM

scanning electron microscopy

- XRF

X-ray fluorescence

- ZAC

Zone d’Aménagement Concerté