Published online by Cambridge University Press: 28 January 2005

Mass customization has been identified as a competitive strategy by an increasing number of companies. Family-based product design is an efficient and effective means to realize sufficient product variety, while satisfying a range of customer demands in support for mass customization. This paper presents a knowledge decision support approach to product family design evaluation and selection for mass customization process. Here, product family design is viewed as a selection problem with the following stages: product family (design alternatives) generation, product family design evaluation, and selection for customization. The fundamental issues underlying product family design for mass customization are discussed. Then, a knowledge support framework and its relevant technologies are developed for module-based product family design for mass customization. A systematic fuzzy clustering and ranking model is proposed and discussed in detail. This model supports the imprecision inherent in decision making with fuzzy customers' preference relations and uses fuzzy analysis techniques for evaluation and selection. A neural network technique is also adopted to adjust the membership function to enhance the model. The focus of this paper is on the development of a knowledge-intensive support scheme and a comprehensive systematic fuzzy clustering and ranking methodology for product family design evaluation and selection. A case study and the scenario of knowledge support for power supply family evaluation, selection, and customization are provided for illustration.

Today's highly competitive, global marketplace is redefining the way companies do business. Mass customization (Pine, 1993) is emerging as a new paradigm for manufacturing industries. Hence, variety and customization supplant standardized products, heterogeneous and fragmented markets spring from once homogeneous markets, and product life cycles and development cycles spiral downward (Tseng & Jiao, 1996, 1998). Mass customization aims at delivering a sufficient product variety to satisfy diverse customer needs while maintaining near mass production efficiency (Tseng & Jiao, 1996). To adopt the mass customization paradigm, many companies are being faced with the challenge of providing sufficient variety for the market with as little variety as possible between products to maintain economies of scale, while satisfying a wide range of customer requirements.

A product family (line) refers to a collection of product variants that have similar functions but with different combinations of attribute levels. In a market characterized by a large variety of customer preferences and with intensive competition, companies introduce a product family to satisfy as best as possible the preferences of different customers and also achieve their business goals (Li & Azarm, 2002). Family-based product design is an efficient and effective means to realize sufficient product variety, while satisfying a range of customer demands needed for mass customization (Tseng & Jiao, 1996). Customized product development could be viewed as a configuration design problem. The essence of configuration design is to synthesize product structures by determining what modules or building blocks are in the product and how they are configured to satisfy a set of requirements and constraints. Thus, product/family evaluation plays an important role in this process, as a poor selection of a building block or module or a configuration structure is difficult to be compensated for at later design stages and can give rise to expensive redesign costs (Pahl & Beitz, 1996). Because of its paramount importance in configuration design, the problem of evaluation and selection of alternatives has received enormous attention both in academia and in industry. Although a number of methods have been investigated, there is still much to be desired because of the hindrance inherent in the conceptual evaluation and selection process. Difficulties associated with such a task lie in problem-solving complexity, various decision criteria, and product performance assessment (Jiao & Tseng, 1998a; Zha & Lu 2002a, 2002b).

Design has become increasingly knowledge intensive (Tong & Sriram, 1991a, 1991b; Sriram, 2002). The ability to compete effectively in global markets depends on how well a company is able to exploit various type of knowledge, including corporate expertise. To improve the product family design for mass customization process, it is imperative to provide knowledge support and share design knowledge among distributed designers. In our previous work (Zha & Lu, 2002a, 2002b), a general high-level knowledge-intensive support framework was proposed for customer-driven, modular platform-based product family design and design for mass customization. Some fundamental research issues were identified and addressed. A prototype Web-based knowledge system to support product family design has been developed and tested with a power supply product family. On the basis of the previous work, this paper aims to develop a knowledge support paradigm for product family design evaluation and selection in customer-driven design for mass customization (CDFMC). The focus of this paper is on the development of a comprehensive systematic fuzzy clustering and ranking methodology for product family design evaluation and selection in the context of CDFMC.

The organization of this paper is as follows. Section 2 reviews the previous research related to product family design evaluation and selection. Section 3 addresses issues and technologies for customer-driven modular product family design for mass customization. Section 4 discusses a knowledge support scheme for product family evaluation in design for mass customization. A fuzzy clustering and ranking methodology is proposed and discussed in detail. Section 5 provides a case study and a scenario of knowledge support for product customization in power supply family design. Section 6 presents the research results, and discusses the benefits or advantages of the proposed approach. Section 7 summarizes and concludes the paper.

This section briefly reviews previous research work and the current status of research related to product family design for mass customization and design alternative evaluation and selection.

The literature on design alternative evaluation and selection can be generally classified into five categories (Jiao & Tseng, 1998a): multicriteria utility analysis, fuzzy set analysis, design analytic methodology, the hybrid approach, and the information content approach. The following review will be mainly on these first three approaches, because they are commonly used.

Multicriteria utility analysis is an analytical method for evaluating a set of alternatives, given a set of multiple criteria. It has been widely applied in the areas of engineering and business for decision making. For example, Thurston (1991) has applied this technique to the material selection problem, where alternatives are evaluated based on utility functions that reflect the designer's preferences for multiple criteria. Mistree et al. (1992, 1995) modeled design evaluation and optimization as a compromise decision support problem and employed goal-programming techniques to make optimal selection decisions. Although mathematical programming and utility analysis enhance algorithm-rigorous optimization modeling, such methods require the expected performance with respect to each criterion to be represented with a quantitative form. They are not appropriate for use in the early design stage, where some qualitative design criteria, that is, intangible criteria, are involved and difficult to quantify (Thurston & Carnahan, 1992; Thurston & Crawford, 1994; Thurston & Locascio, 1994).

Fuzzy analysis, based on the fuzzy set theory (Zadeh, 1965), is capable of dealing with qualitative or imprecise inputs from designers. It does so by describing the performance of each criterion with some linguistic terms, such as “good,” “poor,” and “medium.” It has proven to be quite useful in decision-making problems with multiple goals or criteria, especially rank alternatives at very early stages of the preliminary design process (Zimmermann, 1996). The fuzzy set analysis approach is most appropriate when there are imprecise design descriptions, whereas a probability analysis approach is most appropriate for dealing with stochastic uncertainty. The fuzzy set analysis approach excels in capturing semantic uncertainty with linguistic terms. However, it requires discreet deliberation in dealing with crisp information, and a domain-specific method is needed to fuzzify each tangible criterion whose evaluation is naturally estimated as an ordinary real variable. Another challenge for the fuzzy set analysis approach is the incomparability between various criteria, which necessitates some mechanisms to be capable of converting various types of performance evaluation with respect to different criteria to a common metric so as to specify suitable membership functions for them.

Design evaluation usually involves both tangible and intangible criteria, along with quantitative and qualitative performance measures. This necessitates the hybrid approach of combining the quantitative, normative problem structuring capabilities of operations research techniques with the qualitative, descriptive problem-solving approach used in artificial intelligence techniques. For example, Maimon and Fisher (1985) presented a robot selection model using integer programming and a rule-based expert system. Considerable research efforts have been devoted to fuzzy goal programming to model mathematically the imprecise relationships using fuzzy goals and soft constraints. However, they mostly model a particular aspect of uncertainties in design evaluation, such as imprecise relationships, imprecise information, and uncertain information (Knosala & Pedrycz, 1992). It is difficult for a fuzzy goal-programming model to consider all sources of uncertainty coherently at the preliminary design stage (Carnahan et al., 1994). In addition, computational complexity is a key issue, especially if a large number of design alternatives and criteria are involved (Boender et al., 1989; Wang, 1997). There are also many other product feasibility and quality assessment tools that are useful for planning the design of products, such as quality function deployment (Clausing, 1994), concurrent function deployment (Prasad, 1996), concept selection matrix (Pugh, 1991), Taguchi robust design method (Taguchi, 1986), and so forth. Although these methodologies provide high-level guidelines for design evaluation, detailed supporting techniques are essential; models, methods, metrics, and measures (i.e., the 4Ms) are the core in integrated product development.

To reflect customer preferences in multicriteria design evaluation, numerous evaluation procedures take into account the relative importance or weighting factor for each criterion (Jiao & Tseng, 1998a). Frazell (1985) assigned weights to criteria on a 0–100 scale. Sullivan (1986) presented a linear additive model, in which ranking is included. Huang and Ghandforoush (1984) proposed another procedure for quantifying subjective criteria, in which they compute intangible criteria measures as the multiplication of the intangible criterion weights by the subjective customer rating. Dixon et al. (1986) measured the performance by degree of satisfaction, ranging from excellent to unacceptable, and combined this measure with priority categories of high, moderate, or low to evaluate the design. Nielsen et al. (1986) used factor criteria to establish the level of importance of attributes. A priority level, such as absolutely necessary, important, or desirable, is indicated for each factor criterion, and is used to guide decision making. The main drawback of these evaluation methods is that they ignore the inconsistency issue on the part of the decision maker, which occurs when the solution does not match the decision maker's preference and results from the randomness of the decision maker's judgments (Saaty, 1991). The analytical hierarchy process (AHP) was developed to deal with the decision-maker's inconsistency and to mimic the human decision-making process (Saaty, 1991). It determines weights by means of pairwise comparisons between hierarchical decision levels. The AHP has been proven to be a more rigorous procedure for determining customer preferences, and has been approached from the fuzzy point of view by Boender et al. (1989). Carnahan et al. (1994) proposed an approach to fuzzify the weights after they have been obtained by the AHP.

Various approaches and strategies for designing families of products and mass customized goods are reported in the literature. These techniques appeared in varied disciplines such as operations research (Gaithen, 1980), computer science (Nutt, 1992), marketing/management science (Kotler, 1989; Wheelwright & Sasser, 1989; Rothwell & Gardiner, 1990; Sanderson, 1991; Wheelwright & Clark, 1992; Meyer & Utterback, 1993; Pine, 1993), or engineering design (Ishii, Juengel, & Eubanks, 1995; Stadzisz & Henrioud, 1995; Chen et al., 1996; Martin & Ishii, 1996; McKay et al., 1996; Tseng & Jiao, 1996, 1998; Fujita & Ishii, 1997; Fujita et al., 1998; Simpson, 1998, Gonzalez–Zugasti, 2000; Simpson et al., 2001; Zha & Lu, 2002a, 2002b).

To evaluate a family of products for mass customization, suitable metrics are needed to assess the appropriateness of a product platform and the corresponding family of derivative products (Krishnan & Gupta, 2001). The metrics should also be useful for measuring the various attributes of the product family and assessing a platform's modularity. With respect to the process of product family design for customization, the evaluation of product family design was viewed from three different level perspectives: product platform, product family, and product variant (Zha & Sriram, 2003). The product variant level evaluation is actually the same as or similar to the individual product design evaluation. Various traditional design evaluation approaches reviewed above are applicable, and the metrics for this level of evaluation include cost, time, assemblability, manufacturability, and so forth. The platform and family level evaluation is focused on the overall benefit of product family development to the company, and the metrics at these levels reflect that the main goal of designing products/families is to maximize the benefits to the company. Currently, there are many marketing or business, econotechnical metrics that can be used for measuring performance or evaluation in CDFMC on the first two levels (Simpson, 1998; Zha & Sriram, 2003). For example, platform efficiency and platform effectiveness defined by Meyer et al. (1997) can be used to measure R&D performance, focused on platforms and their follow-on products (variants) within a product family. Other methods include cycle time efficiency, technological competitive responsiveness, and profit potential (Meyer & Lehnerd, 1997).

Specifically, the approaches for product family design evaluation and selection have received much attention from researchers in both engineering design (for the designer) and management and marketing (for the customer). From an engineering design perspective, multiobjective optimization models have been used to obtain a performance optimal product family (line) to satisfy a range of customer requirements, and to quantify the influence of a product platform (Simpson, 1998; Nelson et al., 1999; Li & Azarm, 2000, 2002; Simpson et al., 2001). In addition, the engineering design literature reports on models that account for cost, expected profit, risks, and benefits of delayed decisions in producing a product family (line; Fujita et al., 1998; Gonzalez–Zugasti, 2000). From the management and marketing perspective, research efforts have been made mainly on product line positioning (Green & Krieger, 1985; Kohli & Sukumar, 1990; Dobson & Kalish, 1993). In the product line-positioning problem, a line of products is selected from a set of already available design alternatives, considering cost, customers' preferences, and market competition to optimize a business goal such as profit or market share. Li and Azarm (2002) proposed an integrated approach for a product line design selection based upon marketing potential of candidate product lines, those that have from an engineering design point of view the best possible variants. The integrated approach accounts for a large variety of customers' preferences, market competitions, and commonality (i.e., multicomponent variants that share one or more components across the product line). However, the previous work did not sufficiently account for uncertainties of parameters such as customer preferences, product's life cycle, market size, discount rate, and so forth.

The literature review indicates that several quantitative frameworks have been proposed for product family design evaluation and selection. They provide valuable managerial guidelines in implementing the overall platform-based product family development. However, there are very few systematic qualitative or integrated intelligent methodologies to support the product development team members who adopt the platform product development practice, despite the progress made in several research projects (Zha & Lu, 2002a, 2002b; Simpson et al., 2003; Zha & Sriram, 2003).

The approach advocated in this work is for companies to realize a family of products that can be easily modified and quickly adapted to satisfy a variety of customer requirements or target-specific market niches. Details about the knowledge-supported product family design for mass customization are discussed below.

The essence of mass customization is to satisfy customers' requirements precisely without increasing costs, regardless of how unique these requirements may be. That is, a manufacturer has to perceive and capture latent market niches and correspondingly develop its technical capabilities to meet diverse customer needs. To gain market advantage, a manufacturer should outclass competitors in either quality or cost or quick response, or a combination of one or more. Therefore, the requirements of mass customization lie in four aspects: time to market (quick responsiveness), variety (customization), flexibility, and economies of scale (mass efficiency). There are eight identified strategies that have worked in many circumstances (Baudin, 2001).

Considering the above requirements, the main technical challenge in developing a coherent framework for mass customization is in the ability to simultaneously satisfy the following requirements within a single approach (Tseng & Jiao, 1996).

With regard to the above challenges and strategies, this research investigates mass customization from a product development perspective, namely CDFMC, based on the belief that mass customization can be effectively approached from a design perspective (Tseng & Jiao, 1996, 1998). Essentially, the approach includes customers in the product development life cycle through proactively connecting customer needs to the capabilities of a company. The primary focus of CDFMC is to elevate the current practice from designing individual products to designing product families. In addition, CDFMC advocates extending the traditional boundaries of product design to encompass a larger scope spanning from sales and marketing to distribution and services (Tseng & Jiao, 1998). To support customized product differentiation, a product family platform is required to characterize customer needs, and subsequently to fulfill these needs by configuring and modifying well-established building blocks.

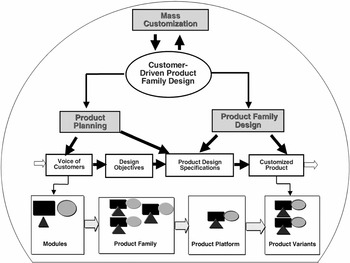

Figure 1 outlines the concept for CDFMC used in this research. It is an adaptation of the process model presented by Barkmeyer et al. (1997). The whole process of CDFMC ranges from capturing the voice of the customers (VoCs) and market trends for generating product design specifications (PDSs), designing a product platform for generating product variety or a product family, to deriving and customizing product variants by evaluating and selecting a product family for customers' satisfaction. It can be divided into two major stages: product/family planning and family design. The product planning stage embeds the VoCs into the design objective and generates PDSs. The product family design stage generates sufficient product variety to satisfy a range of customer demands. The bottom of Figure 1 illustrates the concept of module-based product family design process.

The framework for CDFMC based on the module-based product family design.

Figure 2 illustrates a product family architecture (PFA) to support mass customization (Du et al., 2000). From the customers' point of view, products are functional features F = {f} and the related feature values {f*}. A product family, consisting of product variants {PV1, PV2, PV3, …, PVi, …, PVm}, is designed to address the requirements of a market segment {customer1, customer2, customer3, …, customeri, …, customerm}, wherein the customers share some similar/common requirements F0 = {f0*} and have their special requirements F* = {f1*, f2*, f3*, …, fn*}. Customer requirements characterized by the different combinations of functional features can be satisfied by the product variants derived by the common bases {CB} and differentiation enablers {DE} of the product family. It is the configuration mechanisms that determine the generative aspect of a product family. Details about the PFA and its three elements (the common base, differentiation enabler, and configuration mechanism) can be found in Tseng and Jiao (2001).

The architecture of the product family for mass customization.

The fundamental issues underlying the whole product family design for mass customization process include productinformation modeling, PFA, product platform and variety, modularity and commonality, product family generation, product assessment and customization, and so forth. (Jiao & Tseng, 1998b; Zha & Lu, 2002a, 2002b). An effective product family platform can allow a variety of derivative products to be created more rapidly and easily, with each product providing the features and functions desired by a particular market segment (Simpson, 1998; Simpson et al., 2001). Usually, product families have an impact on a firm's ability to efficiently deliver high product variety, and can have profound implications for subsequent product development activities. The product family design is tightly linked to several issues of importance to the entire enterprise: product change, product variety, component standardization, product performance, manufacturability, and product development management.

From the aspect of product design, component standardization through a modular architecture has clear advantages in the areas of cost, product performance, and product development. Decomposing the problem into modules and defining how modules are related to one another is an important step toward a modular design process. Modular systems provide the ability to achieve product variety through the combination and standardization of components (Kusiak & Huang, 1996). Fujita and Ishii (1997) decompose product families into systems, modules, and attributes. Under the hierarchical representation scheme shown in Figure 3, product variety can be implemented at different levels within the product architecture. This is actually a modularization process from a certain perspective, as shown in Figure 4. The modularization process can be achieved through the following steps (Zha & Lu, 2002a, 2002b).

Product families, modules, and attributes.

The modularization process in modular product family design.

In summary, the major steps for creating a modular product family can be outlined as follows: decompose products into their representative functions; develop modules with one–one (or many–one) correspondence with functions; group common functional modules into a common product platform; and standardize interfaces to facilitate addition, removal, and substitution of modules. The module-based product family design process generates a reconfigurable product platform that can be easily modified and upgraded through the addition, substitution, and exclusion of modules. The product customization stage aims at obtaining a feasible architecture of a product variant (i.e., a family member) through exploring product family module space according to customer requirements (Fujita & Ishii, 1997). There are two steps involved in this stage. First, customer requirements such as function, assembly, and reuse need to be converted to constraints (Suh, 1990). Then, the reasoning is performed at two levels, namely, module and attribute levels, to determine (evaluate and select) the feasible product variants.

The conceptual framework shown in Figure 1 demonstrates the process of customer-driven product family design for mass customization, which ranges from capturing VoCs, analyzing market trends, and generating design objectives and PDSs to customizing products for customer satisfaction. To assist the designer during this process, a knowledge support framework is further developed based on the CDFMC concept, as illustrated in Figure 5.

The knowledge support framework for CDFMC.

Product family design knowledge is classified into two categories: product/family information and knowledge, and product/family design process knowledge. These two categories of knowledge are utilized to support CDFMC that has two application scenarios: product planning and product family design (Zha & Sriram, 2003). The knowledge support scheme aims to provide support for customer requirements' modeling, product architecture modeling, product platform establishment, product family generation, and product family assessment for customization. The knowledge support scheme for modular product family design and its key research issues are described in (Zha & Lu, 2002b).

As shown in Figure 6, the product family design process in the context of CDFMC can actually be divided into two major stages: product platform building, and product variant assessment. The generation of product platform and family in the product platform building stage is implemented through product (family) planning for design specifications and modular and configuration design, while the product family evaluation and selection for customization is implemented by assessing product variants generated from a product platform. The fundamental issues involved in the product family design process have been addressed in Zha and Lu (2002a, 2002b) and Zha and Sriram (2003), which include a knowledge-intensive support strategy and its implementation for platform-based product design and development.

Modular product family design for the mass customization process.

During the process of modular product family design, a wide variety of product families can be generated by the selection and assembly of modules or predefined building blocks at different levels of abstraction, which satisfy diverse customization requirements. The essence of CDFMC lies in synthesizing product structures by determining what modules or building blocks are in the product and how they are configured to satisfy a set of requirements and constraints, which are family generation, evaluation, and selection. An incorrect or even a poor selection of either a building block or a module can rarely be compensated for at later design stages, and can give rise to extensive redesign costs (Pahl & Beitz, 1996). Thus, product family design evaluation and selection is crucial for CDFMC. To this end, a knowledge support scheme is developed in this research. Therefore, the remainder of this paper will focus on how the product family design knowledge base or repository (Zha & Sriram, 2003) supports the designer to perform product family evaluation and selection.

This section begins with a summary of the knowledge decision support scheme for product family design evaluation and selection. It then presents evaluation/customization metrics applied in the product family design for mass customization process. Finally, it describes a fuzzy clustering and ranking model for classification, evaluation, and selection of product family design alternatives.

The design space for product configuration during module reasoning is very large for a complex system. The designer is required to consider not only the product functionality, but also some other criteria including compactness and other life-cycle issues, such as assemblability, manufacturability, maintainability, reliability, and efficiency. Some criteria may contradict each other. Designers should analyze the trade-off among various criteria and make the “best” selection from a number of design alternatives.

In contrast to the traditional approaches (Pahl & Beitz, 1996), we propose a knowledge-based decision support approach for product family evaluation and selection for customization, as shown in Figure 7. Typically, this stage generates a feasible set of products from a product platform as an input and a customized product as an output. In this process unacceptable alternatives are eliminated. The knowledge resources utilized in this process may extensively include differentiating features, customers' requirements, desirabilities, preferences and importance (weights), trade-offs (e.g., market vs. investment), and utilities functions, and heuristic knowledge, rules, and so forth. Because of the fuzziness of the VoCs or customer requirements/preferences, it is even more difficult to model and assess the performance of a product platform/family and product variants. The kernel of the knowledge decision support scheme is fuzzy clustering and ranking algorithms for design evaluation and selection that will be discussed below.

The knowledge-based decision support scheme.

In this research, the evaluation of product family design is viewed from three different level perspectives: product platform, product family, and product variant (Zha & Sriram, 2003). The metrics for the product variant level of evaluation include cost, time, assemblability, manufacturability, and so forth. For the platform-based family level evaluation, many marketing, or business, econotechnical metrics are used, including platform efficiency, platform effectiveness, and cycle time efficiency. In addition, the following two typical metrics were used (Simpson, 1998; Zha & Sriram, 2003):

Therefore, they can be represented by the following two equations:

where NTM is the number of targetable market niches, NM is the number of total markets, CM is the manufacturing equipment costs, and Nv is the number of product varieties. Of course, a trade-off also exists between the market efficiency and the investment efficiency, as an increase in the investment efficiency through a decrease in product variety can cause a decrease in the market efficiency.

In this section, a fuzzy clustering and ranking methodology is proposed for product family design evaluation and selection in the context of CDFMC. The algorithms are constructed using fuzzy sets/theory to solve a fuzzy clustering/classification and fuzzy multicriteria decision-making (FMCDM) problem. The fuzzy clustering algorithm is used to classify design alternatives or variants and determine similarity and commonality between modules, product variants, and product families. The FMCDM problem can be defined as follows: given a set of design alternatives or variants, evaluate and select a design alternative or variant that satisfies customer needs, meets design requirements, and complies with the technical capabilities of a company.

Based on the systematic approaches (Suh, 1990; Pahl & Beitz, 1996), a reasonable number of possible design alternatives can be obtained using various design solution generation techniques at the conceptual design stage. Each subfunction may correspond to a collection of available solution principles. These principles determine design alternatives or variants through mappings from functions to forms. Assume that there are a total of n subfunctions, each of them having mi possible solution principles. Combining these solutions, all theoretically possible overall solution variants can be obtained as schematically illustrated in Table 1. Consequently, the cluster analysis for pattern recognition (Kandel, 1982; Gui, 1993) can be used to sort a product family design data set into families. This is very crucial for determining the similarity between modules and also the commonality between product variants and product families.

Various combinations of solution principles, of which boxed areas belong to the same family

Generally, given that there are m design patterns (a1, a2, …, am) contained in the design space (S), the process of clustering can be formally stated as seeking the regions s1, s2, …, sk such that every ai (i = 1, …, m) falls into one of these regions and no ai falls into two regions, that is,

. Clustering algorithms must be based on some natural associations according to some similarity measures, and the patterns are described by a set of numerical measures or linguistic variables. The similarity measure or dissimilarity measure is usually given in a numeric form to indicate the degree of resemblance between modules or product variants in a family:

Fuzzy similarity matrices between product variants (PV-A, PV-B) in a family.

A fuzzy similarity matrix between conceptual gear-reducer layout variants in a family.

It is noted that given any two objects (modules or product variants) at some level they can be grouped into the same cluster. If these two objects are always kept within one family at all later levels, then the clustering sequence is hierarchical. The hierarchical clustering sequence or procedure can be divided into two distinct classes: bottom-up and top-down. The former starts with singleton clusters and forms the sequence by successively merging clusters, whereas the latter starts with all the objects in one cluster and forms the sequence by successively splitting clusters. These two classes of hierarchical procedures are both employed in this research. The top-down (decisive) method is applied in the modularization process discussed in Section 3.3, and its algorithm and mathematical model is illustrated in Figure 4b. The bottom up (agglomerative) method is applied mainly for classification of modules and product variants. The algorithm follows four steps (Gui, 1993):

After obtaining the design alternatives or variants, the next procedure is to examine them against marketing, econotechnical and even ergonomic criteria as well as aesthetic criteria. This is actually a multicriteria decision-making problem. One of the well-known methods for multicriteria decision making is to calculate a weighted average rating (ri) by use of the value analysis or cost-benefit analysis introduced in Pahl and Beitz (1996):

where i = 1, 2, …, m, j = 1, 2, 3, …, n, rij denotes the merit of alternative ai according to the criterion Cj, and wj denotes the importance of criterion Cj in the evaluation of alternatives. The higher ri, the better its aggregated performance. However, this procedure is not applicable for the situations where uncertainty exists and the information available is incomplete. For example, the terms “very important,” “good,” or “not good” are a fuzzy set. Thus, the fuzzy approach for ranking a set of alternatives (variants) against a set of criteria is needed. In what follows, we describe a fuzzy ranking approach that was developed based on fuzzy set theory (Zadeh, 1965; Kickert, 1978; Gui, 1993). Let a set of m alternatives A = {a1, a2, …, am} be a fuzzy set on a set of n criteria C = {C1, C2, …, Cn} to be evaluated. Suppose that the fuzzy rating rij to certain Cj of alternative ai is characterized by a membership function μRij (rij), where rij ∈ R, and a set of weights W = {w1, w2, …, wn} are fuzzy linguistic variables characterized by μWj {wj}, wj ∈ R+. Consider the mapping function gi (zi): R2n → R defined by

where zi = (w1, w2, …, wn, ri1, ri2, …, rin). Define the membership function μ(zi) by

Thus, through the mapping gi(zi): R2n → R, the fuzzy set Zi induces a fuzzy rating set Ri with membership function

The final fuzzy rating of design alternative ai can be characterized by this membership function. But it does not mean the alternative with the maximal μR(ri) is the best one. The following procedure further evaluates the two fuzzy sets as (Gui, 1993)

A combination of these two fuzzy sets induces a fuzzy set I, which can determine a best design alternative with the highest final rating, that is,

Compared to Eq. (3), the fuzzy ranking for design is more flexible and presents uncertainty better. Based on this method, the designer can use linguistic rating and weights such as “good,” “fair,” “important,” and “rather important,” for design alternatives evaluation.

In some cases, a simplified model is employed in integrating linguistic terms and fuzzy numbers into the fuzzy preference model. The universe of discourse is a finite set of fuzzy numbers used to express an imprecise level of performance rating and weight of each criterion. A range of imprecise levels is the linguistic terms “very low,” “low,” “fairly low,” “medium,” “fairly high,” “high,” and “very high.” The linguistic scale is used to transform these linguistic terms of partial performance ratings rij and weights wj of the criteria into triangular or trapezoidal fuzzy numbers defined in the interval [0, 1], where rij denotes the linguistic performance rating with respect to a criterion Cj for a retrieved product variant PVi and wj denotes the linguistic weight of Cj. The aggregation of fuzzy numbers in an analytic form requires a complex arithmetic process. Thus, in this research, an approximate centroid-based defuzzification method is used to defuzzify the fuzzy numbers into crisp values early on, then the defuzzified results can be aggregated easily and the execution is very fast (Zhang et al., 2002). For example, if a fuzzy set is represented as a trapezoidal fuzzy number (see Fig. 10), then it can be parameterized by a quadruple (x1, x2, x3, x4) and its crisp defuzzied value (approximate centroid) is (x1 + x2 + x3 + x4)/4. A triangular fuzzy number (x1, x2, x3) can also be represented as (x1, x2, x2, x3) by a trapezoidal fuzzy number form with its crisp defuzzied value becoming (x1 + x2 + x2 + x3)/4.

A linguistic scale representation for fuzzy customer preferences and performance.

With the approximate centroid-based defuzzification method the fuzzy linguistic performance rating rij and fuzzy linguistic weight wj can be transformed respectively into the crisp performance rating rij ∈ [0, 1] and crisp weight wj ∈ [0, 1]. Thus, the numerical weighted performance rating ri ∈ [0, 1] of a design alternative can be calculated simply using the classic weighted average aggregation method. The key points of this simplification can be understood as: it is a simple scenario; it can also be used for defuzzification.

In the knowledge support scheme, it is important to have a powerful search strategy that will lead to a near optimum solution in a reasonable amount of time. An A* search algorithm (Sriram, 1997) provides a method to achieve this. The system first calculates the weighted performance rating aggregation of each retrieved alternative (variant) by analyzing the trade-off among various criteria. Then it calculates the evaluation index of each design alternative (product variant) by considering all the weighted performance ratings.

After obtaining the numerical weighted performance ratings of all design alternatives or variants, the evaluation index is calculated and used as a heuristic evaluation function (fh) by considering all the weighted performance ratings ri (i = 1, 2, 3, …, m) of its constituent members and the number k of its unsatisfied customer requirements as follows:

where ri ∈ [0, 1] is the numerical weighted performance rating of PVi and 1/ri = (1, +∞) is defined as the performance cost of PVi. A higher weighted performance rating of a product variant corresponds to a lower performance cost. The expression

represents the accumulated performance cost of a design alternative/variant along the search path so far; k is a heuristic estimate of the minimal remaining performance cost of a design alternative/variant along all the possible succeeding search paths; and fh is the estimate of the total performance costs of a design alternative/variant, also called the evaluation index. In the above formula, a higher ri (i.e., the better-aggregated performance of each retrieved PV) and lower m or k (i.e., higher compactness of design alternative/variant) result in a lower fh (lower evaluation index of a design alternative/variant). Thus, at each step of the A* search process, the best design alternative (with the lowest value of the heuristic evaluation function) can be selected by taking into account multicriteria factors, including design compactness and efficiency (market vs. investment) or other life-cycle issues, such as manufacturability, assemblability, maintainability, and reliability.

Because of the complexity and uncertainty of design problems, it is required to further improve the above comprehensive fuzzy clustering and ranking methods. One way to do this is to provide learning ability. In a fuzzy set, a variable v can belong to more than one set, according to a given membership function μx(v). Standard membership function types such as Z, λ, π, and S can be mathematically represented as piecewise linear functions (Zimmermann, 1987, 1996). It can easily be implemented and adjusted by using neural networks. The fuzzy system (e.g., rule block) is the kernel of the whole fuzzy neural network model. It forms the basic scheme of knowledge representation exploited in the fuzzy evaluator.

The neurofuzzy hybrid approach uses a neural network to optimize certain parameters of an ordinary fuzzy system, or to preprocess data and extract fuzzy rules from data (Zha, 2001). The fuzzy evaluator described above involves three basic elements: fuzzification, fuzzy inference, and defuzzification. The fuzzification in the input interfaces translates analog inputs into fuzzy values. The fuzzy inference takes place in rule blocks that contain the linguistic control rules. The output of these rule blocks is linguistic variables. The defuzzification in the output interfaces translates them back into analog variables. Each fuzzy rule can be interpreted as a training pattern for a multilayer neural network, where the antecedent part of the rule is the input and the consequent part of the rule is the desired output of the neural network. There are two main approaches commonly used to implement fuzzy if-then rule blocks by a standard error back propagation network. One is to represent a fuzzy set by a finite number of its membership values (normally by linear functions). The other is to represent fuzzy numbers by a finite number of α-level sets. The former approach is adopted in this research. Suppose that [α1, α2] contains the support of all the Ai we might have as input to the system, and [β1, β2] contains the support of all the Bi we can obtain as outputs from the system, i = 1, 2, …, n. If m ≥ 2 and n ≥ 2 are positive integers, then

where, 1 ≤ i ≤ m, and 1 ≤ j ≤ n. Thus, a discrete version of the continuous training set can be composed of the following input/output pairs: {(Ai(x1), …, Ai(xn)), (Bi(y1), …, Bi(ym))}, i = 1, …, n. Using the notations aij = Ai(xj), bij = Bi(yj), the fuzzy neural network turns into an n input and m output crisp network, which can be trained by the generalized delta rule. Figure 11 shows a network trained on membership values of fuzzy numbers.

A network trained on membership values for fuzzy numbers.

This section provides a case study of the power supply family design evaluation and selection for mass customization and introduces a prototype for a product family design advisory system for decision support.

Power supplies are necessary components of all electronic products. Because of diverse requirements, power supply products (e.g., http://www.artesyn.com) are often customized (Jiao & Tseng, 1998a). To illustrate and validate the proposed knowledge support scheme, a scenario illustrating the knowledge support for a power supply family design evaluation and selection for customization is provided.

From a customers' point of view, a power supply product is defined on the following required features (RFs): power, output voltage (OutV), output current (OutC), size, regulation, mean time between failure (MTBF), and so forth. From an engineer's point of view, the power supply product is designed by determining these variables (parameters; DPs): core of transformer (Core), coil of transformer (Coil), switch frequency (SwitchF), rectifier, heat sink type (TypeHS), heat sink size (SizeHS), control loop (Control), and so forth. Figure 12 shows the relationships between RFs, DPs, configurations, and clusters. Three product families (I, II, and III) are generated based on three different clusters, which have four, five, and three base products, respectively. Each cluster has its own range/limitation with regard to particular product features and/or design parameters. The modular design of power supply products is based on the work in (Tseng & Jiao, 1998; Zha & Lu, 2002a, 2002b). When the product configuration is carried out, the design requirements and constraints are satisfied especially in terms of product functions or function features. From the assembly or disassembly/maintenance point of view, it had better be that the parts with low exchange rate are placed inside of the product, but the locations of some parts are fixed in advance because of design constraints.

Configurations and clusters of power supply products.

With respect to the knowledge decision support scheme for product evaluation (Fig. 7), a scenario for knowledge support for power supply product evaluation for customization in Family I is shown in Figure 13. The customer requirements for Family I power supplies include AC/DC, 45 W, 5 V, and ±15 V, 150 kh, $20–50, and so forth. The knowledge decision support system first eliminates unacceptable alternatives and determines four acceptable alternatives: NLP40-7610, NFS40-7610, NFS40-7910, and NFS 42-7610. The final design decision can be reached based on the knowledge resources given in Figure 14, including differentiating features (MTBF, price, and special offer) and their utility/membership functions, fuzzy rules, and so forth. The final design decision made by the system is NFS42-7610 as it has maximum MTBF, medium price, and a special autostart function, and it is acceptable based on the rules.

A scenario of knowledge support for product evaluation and selection for customization.

The knowledge used in power supply product evaluation and selection for customization.

To verify and validate the knowledge support scheme, a prototype called Design Advisor has been developed. It is a Web-based multitier system written in JavaTM, incorporating the Java Expert System Shell, Jess/FuzzyJess (Friedman–Hill, 1999; Samuel & Bellam, 2000; National Research Council of Canada, 2003). The system consists of a cluster analysis module, ranking module, selection module, neurofuzzy module, and visualization and explanation facilities. The Design Advisor system is a subsystem of the knowledge-intensive support system for product family design described in Zha and Lu (2002a, 2002b) and Zha and Sriram (2003). The current capabilities of the prototype include capturing and browsing the evolution of product families and product variant configurations in product families, ranking and evaluation and selection of product variants in a product family.

The comprehensive fuzzy decision support system can visualize and explain the reasoning process. This is a big advantage over the traditional approach. In this subsystem, a tracing approach using a linear chain list (Rule_Used_No) is used for addressing the explanation facilities:

A linear chain list records the number of successful rules during reasoning process and stores them in a knowledge unit. The designer/user consultation is facilitated by a backtracking mechanism like Prolog. With this subsystem, the designer can represent the design choices available as a fuzzy AND/OR tree. The fuzzy clustering and ranking algorithms employed in the system are able to evaluate and select the (near) overall optimal design that best satisfies customer requirements. The selected design choice is highlighted in the represented tree. Figure 15 gives two screen snapshots for the prototype evaluation system used for the power supply concept evaluation and selection.

Screen snapshots for a power supply product family evaluation and selection session.

The developed approach, which differs from existing methods and systems (e.g., Jiao & Tseng, 1998a), is knowledge based and embodies an effective and efficient method to evaluate and select design alternatives or product variants in a product family. The system described above can provide advisory service for design of mass customized products and explain the results. Specifically, it is able to provide a common language at the concept level, allowing a designer to describe a design alternative or product variant so that an expert advisory system can decide and select which design alternative and product variant can satisfy the customers' requirements. This means that the system is designed as a tool for finding a “good” concept/solution for a product while still at the conceptual level of design. It makes a diverse catalog of design alternatives/product variants available to designers/users so that they can experiment with different requirements/technologies in business.

The Web-based nature of the system provides a flexible platform-independent tool for mass customization, that is, designing and building up a reconfigurable modular product platform and customizing it based on the remote-site customer requirements. The widespread use of the system is likely to lead many companies to put their product database searches on-line, allowing users to filter inventories/catalogs based on user-entered requirements. In addition, the system allows developers to provide intelligent knowledge services and an open environment to support and coordinate highly distributed and decentralized collaborative design and modeling activities for designers/users. A Web-based interface lets designers/users customize products and submit them for review if necessary. Thus, the system provides the remote users advice that indicates which product variant is the most suited to the customers' requirement and how the design could best be modified to satisfy the customers' requirements and constraints. This results in a rapid conversion of customer requirements to product (family) design. In addition, the customer is able to explore more design alternatives.

This paper presented an approach to the knowledge decision support for product family evaluation and selection. A comprehensive fuzzy knowledge support scheme and the relevant technologies were developed for product family evaluation and selection in CDFMC. The developed systematic fuzzy clustering and ranking methodology can model the imprecision inherent in design decision making with fuzzy preference relations and carry out fuzzy analysis and evaluation that is capable of handling linguistic as well as ordinary quantitative information, thus solving the multicriteria decision-making problem. The employment of neural network can adjust membership functions of evaluation and selection criteria and rationalize the determination of customer preferences and incorporates them into fuzzy analysis. Thus, typical barriers to decision-making processes, including incomplete and evolving information, uncertain evaluations, and inconsistency of team members' inputs, can be compensated. The results obtained from the case study illustrate the potential and feasibility of the knowledge-intensive decision support scheme as well as the fuzzy clustering and ranking methodology for use in product family design evaluation and selection. This work can help bring products to market faster, and with more certainty of success. Based on the results of assessment, best practices in industry can be identified. These can help improve product quality, cost, time to market, and right to market. The developed methodology is generic and flexible enough to be used in a variety of decision problems, for example, concept evaluation and selection.

The authors would like to express their gratitude to anonymous reviewers of this paper for their insightful comments and suggestions that helped improve the paper. Commercial equipment and software, much of which are either registered or trademarked, are identified to adequately specify certain procedures. In no case does such identification imply recommendation or endorsement by the National Institute of Standards and Technology, nor does it imply that the materials or equipment identified are necessarily the best available for the purpose.

The framework for CDFMC based on the module-based product family design.

The architecture of the product family for mass customization.

Product families, modules, and attributes.

The modularization process in modular product family design.

The knowledge support framework for CDFMC.

Modular product family design for the mass customization process.

The knowledge-based decision support scheme.

Various combinations of solution principles, of which boxed areas belong to the same family

Fuzzy similarity matrices between product variants (PV-A, PV-B) in a family.

A fuzzy similarity matrix between conceptual gear-reducer layout variants in a family.

A linguistic scale representation for fuzzy customer preferences and performance.

A network trained on membership values for fuzzy numbers.

Configurations and clusters of power supply products.

A scenario of knowledge support for product evaluation and selection for customization.

The knowledge used in power supply product evaluation and selection for customization.

Screen snapshots for a power supply product family evaluation and selection session.